Nhựa LLDPE D139FK của hãng Marlex có chỉ số chảy (MI) = 1 dùng để sản xuất các loại film theo phương pháp thổi như các loại bao bì công nghiệp, bao bì trong suốt.

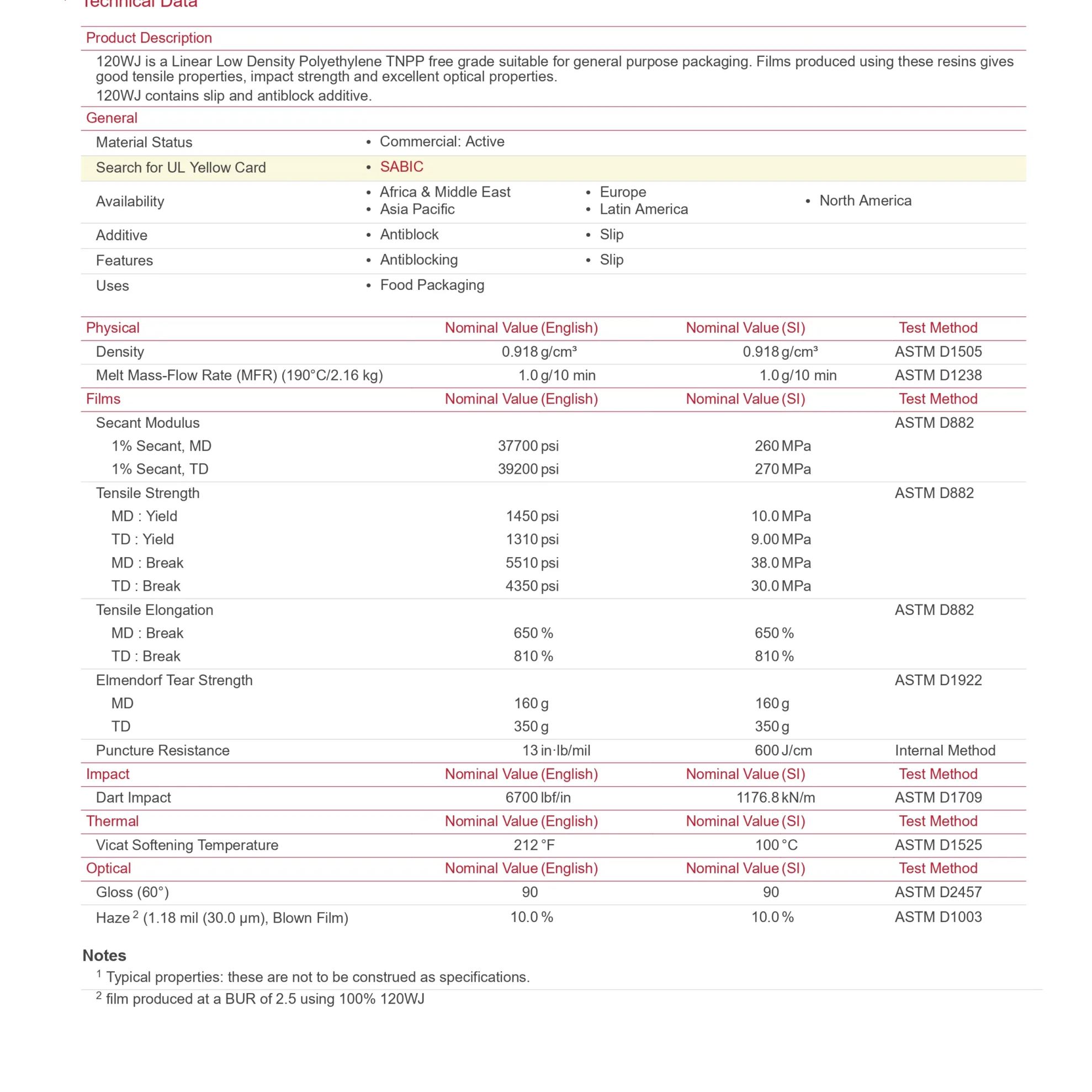

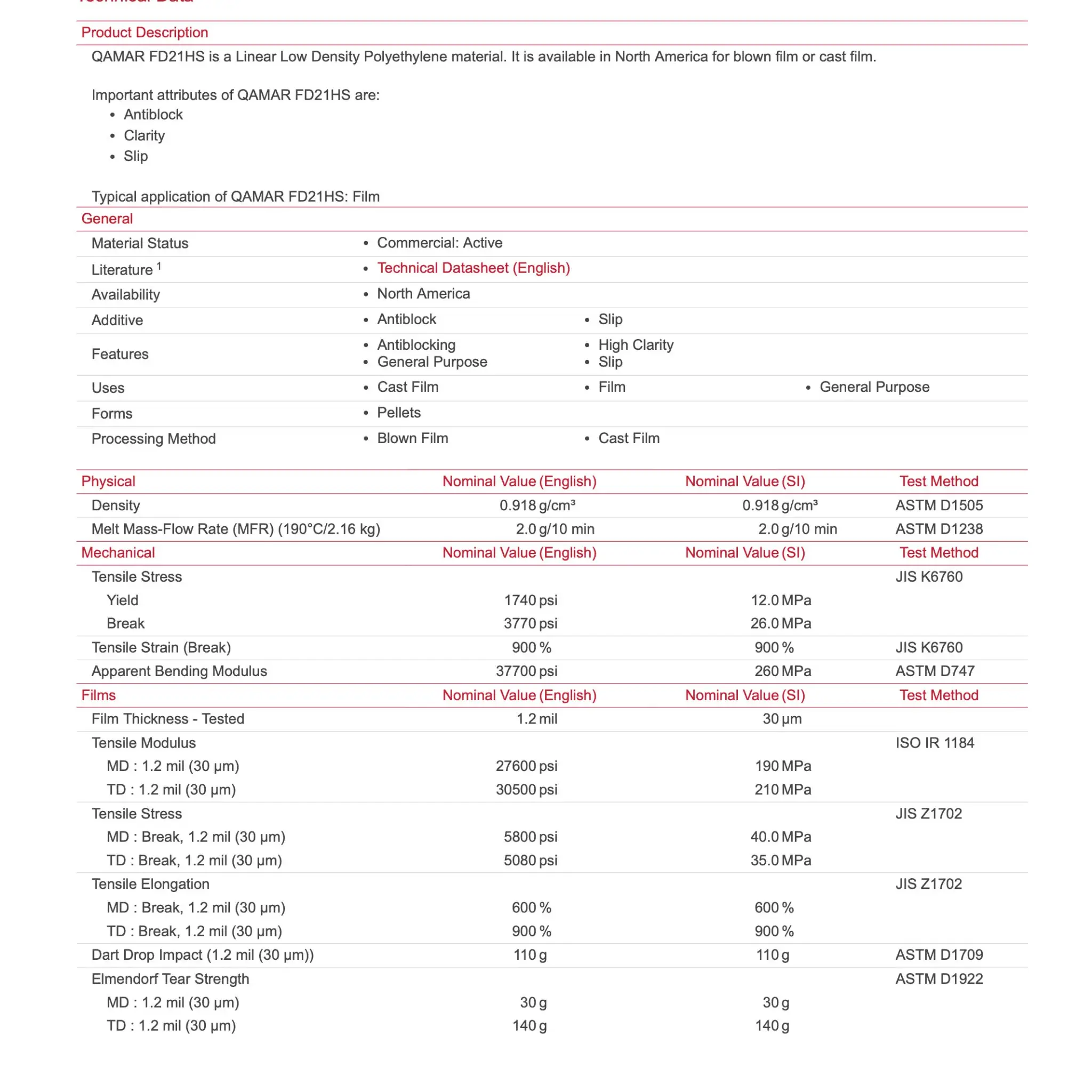

General Material Status Availability Additive Features Uses Forms Processing Method

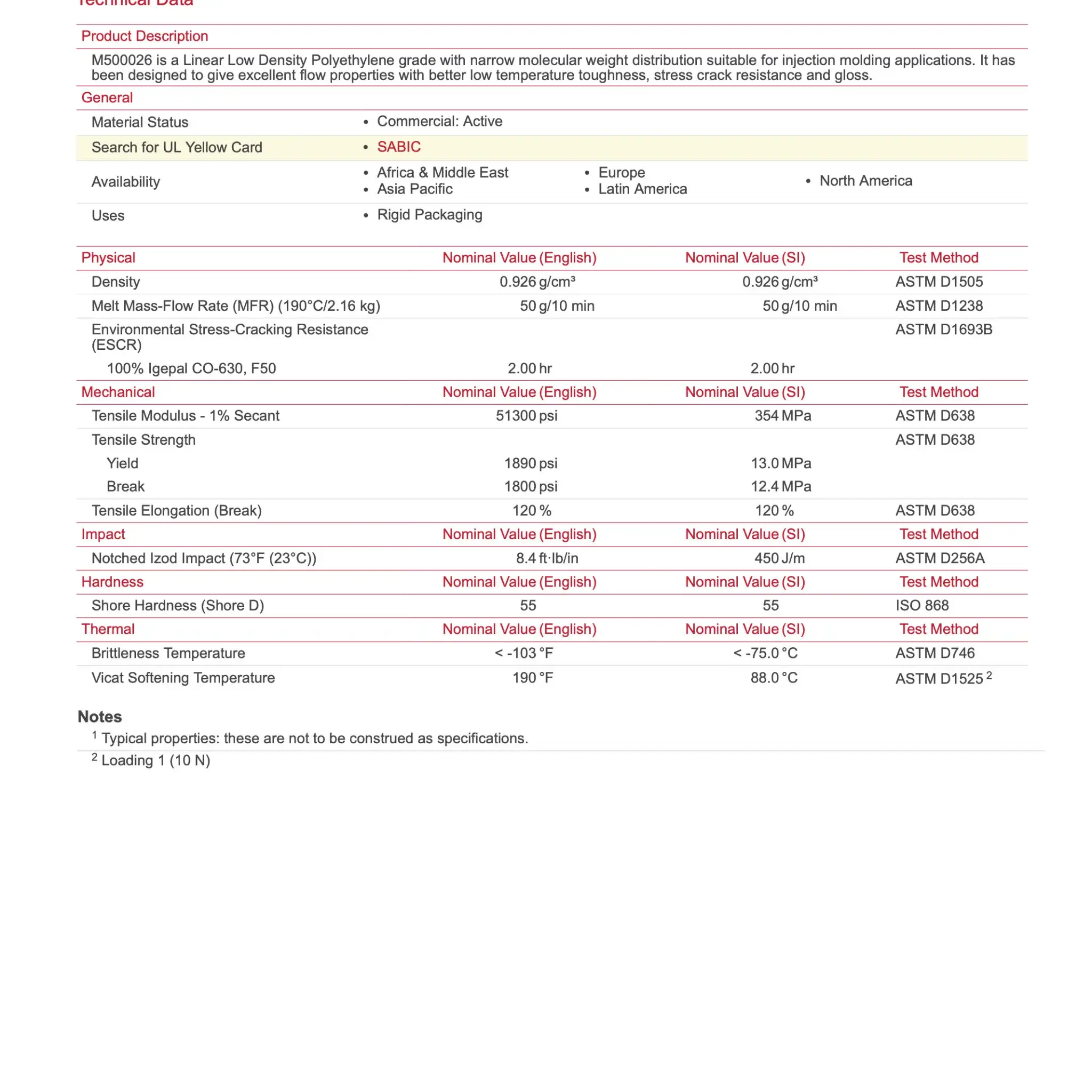

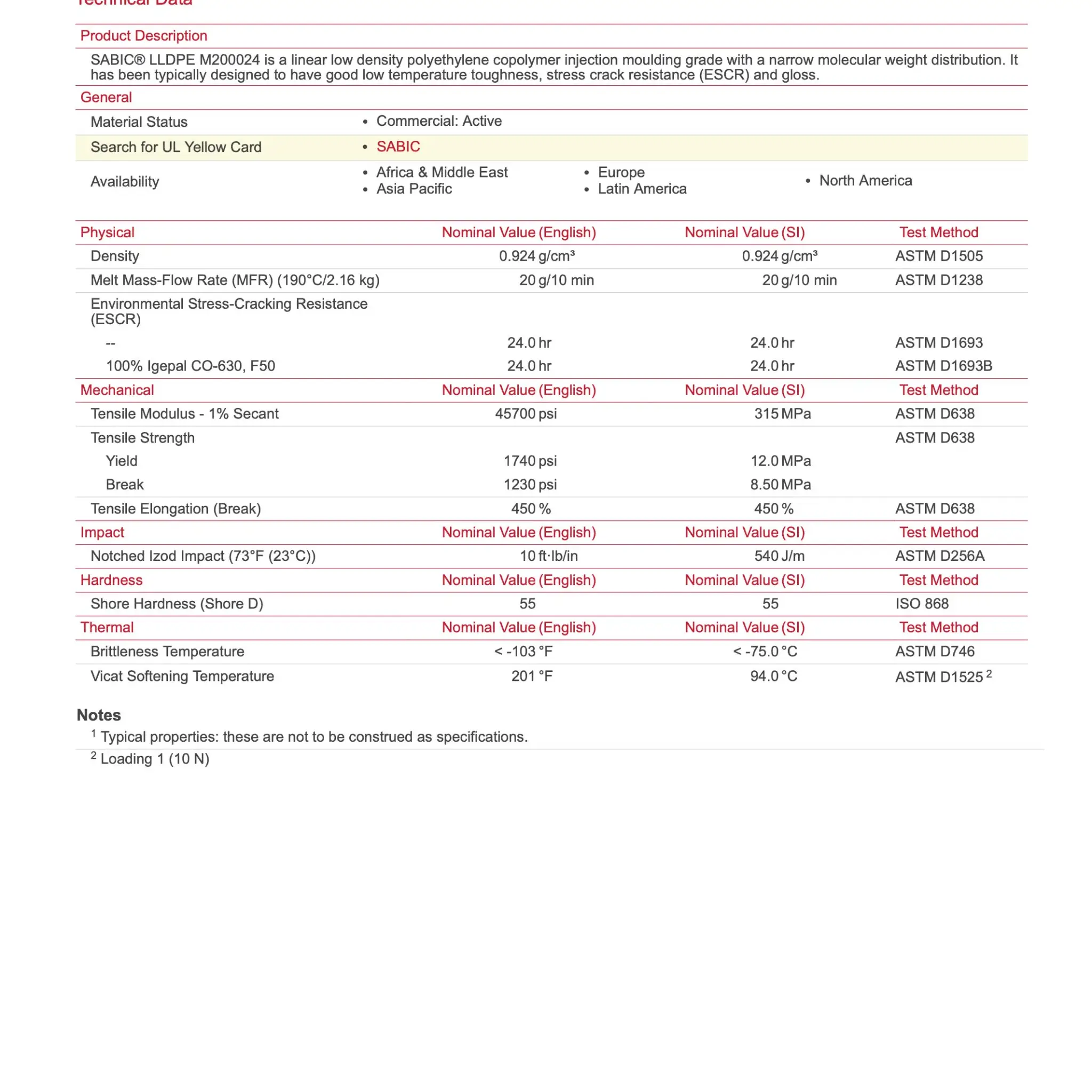

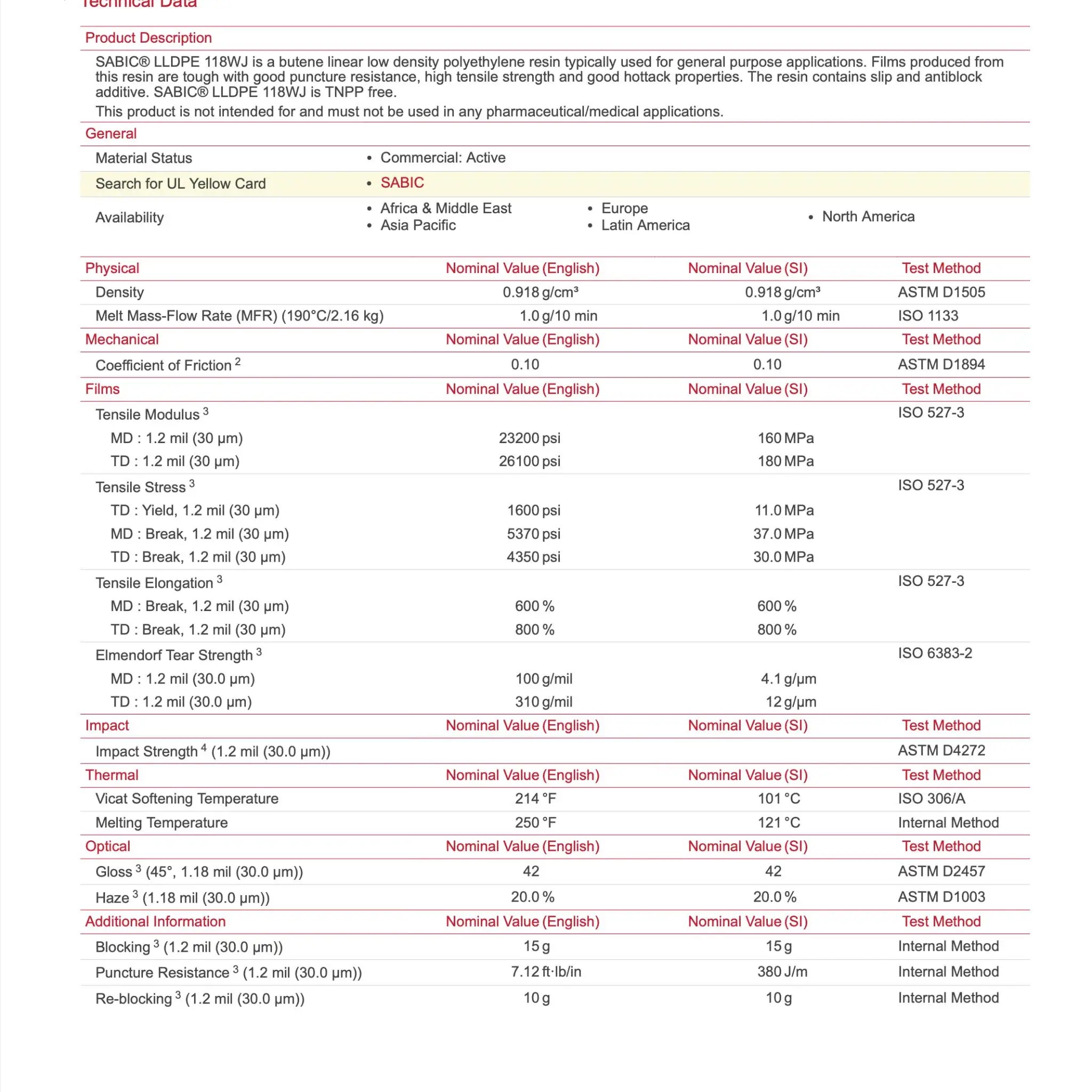

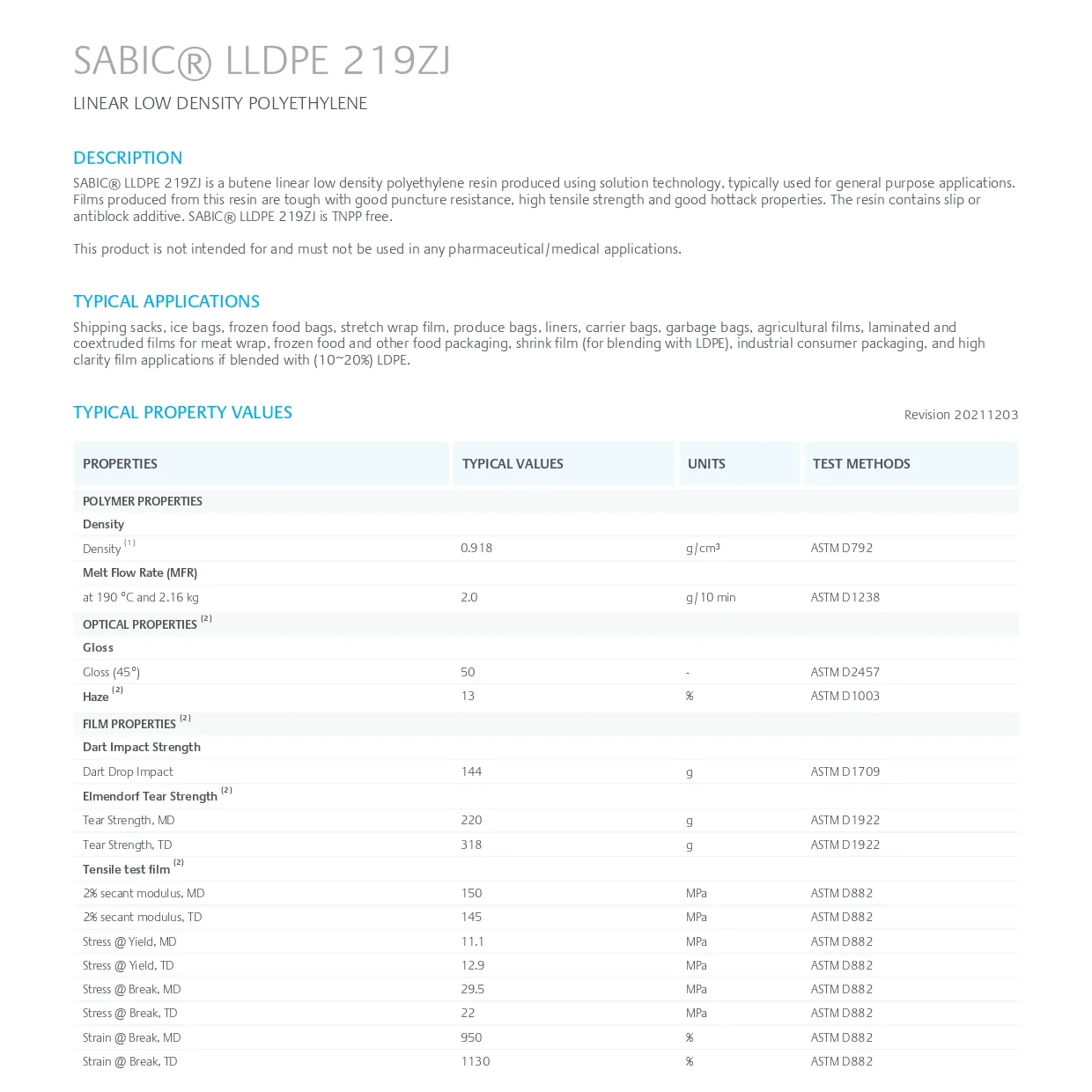

Physical Density ASTM D1505 Melt Mass-Flow Rate (MFR) (190°C/2.16 kg) ASTM D1238

Mechanical Coefficient of Friction (Blown Film) ASTM D1894

Films Film Thickness - Tested Secant Modulus ASTM D882 1% Secant, MD : 1.0 mil, Blown Film ASTM D882 1% Secant, TD : 1.0 mil, Blown Film ASTM D882 Tensile Strength ASTM D882 MD : Yield, 0.98 mil, Blown Film ASTM D882 TD : Yield, 0.98 mil, Blown Film ASTM D882 MD : Break, 0.98 mil, Blown Film ASTM D882 TD : Break, 0.98 mil, Blown Film ASTM D882 Tensile Elongation ASTM D882 MD : Break, 1.0 mil, Blown Film ASTM D882 TD : Break, 1.0 mil, Blown Film ASTM D882 Dart Drop Impact (0.98 mil, Blown Film) ASTM D1709 Elmendorf Tear Strength ASTM D1922 MD : 0.98 mil, Blown Film ASTM D1922 TD : 0.98 mil, Blown Film ASTM D1922 Seal Initiation Temperature (1.0 mil, Blown Film) ASTM F88

Optical Gloss (60°, 0.984 mil, Blown Film) ASTM D2457 Haze (0.984 mil, Blown Film) ASTM D1003