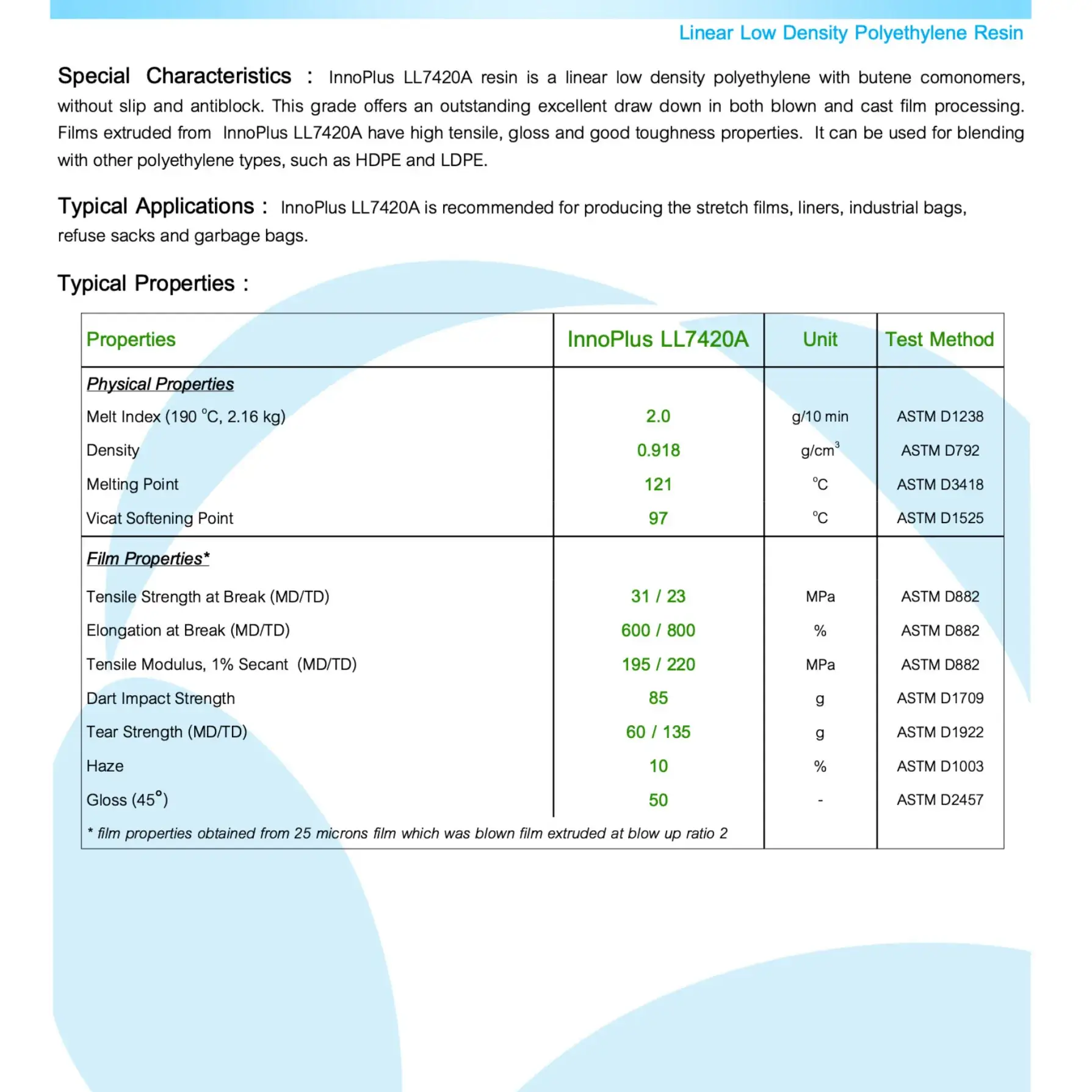

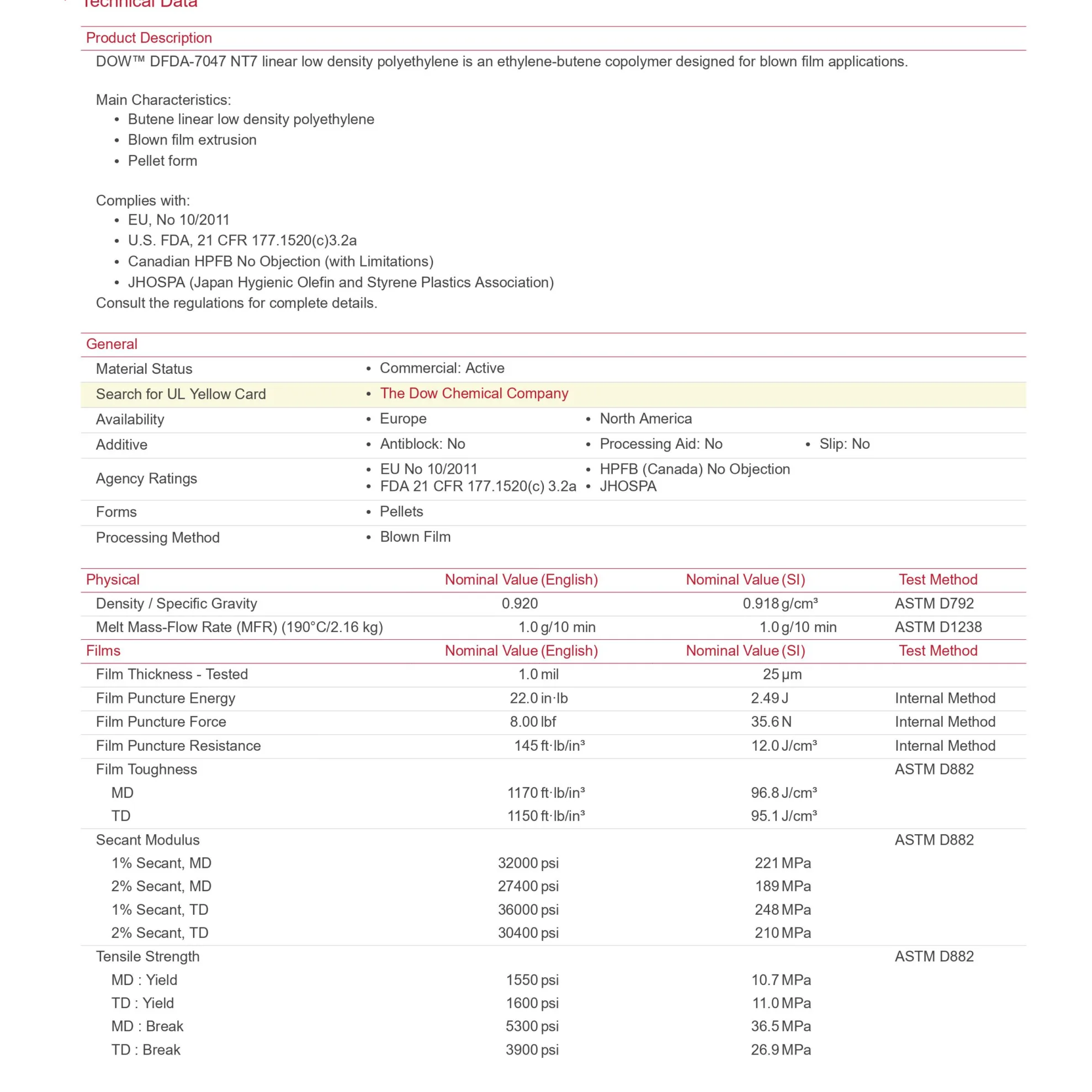

Nhựa LLDPE FC21HN của hãng SPDC có chỉ số chảy (MI) = 1 dùng để sản xuất các loại film theo phương pháp thổi.

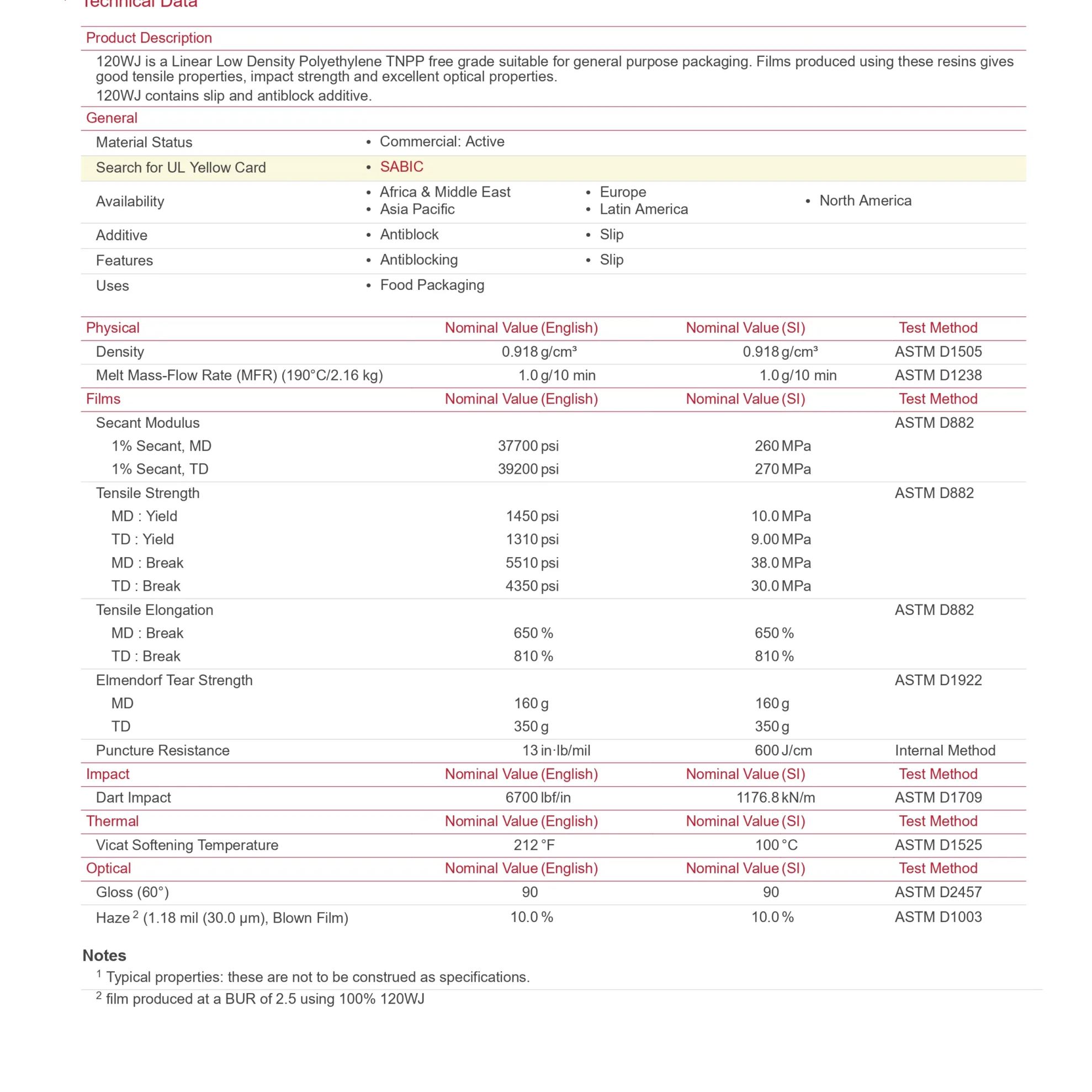

General Material Status Availability Additive Features Uses Processing Method

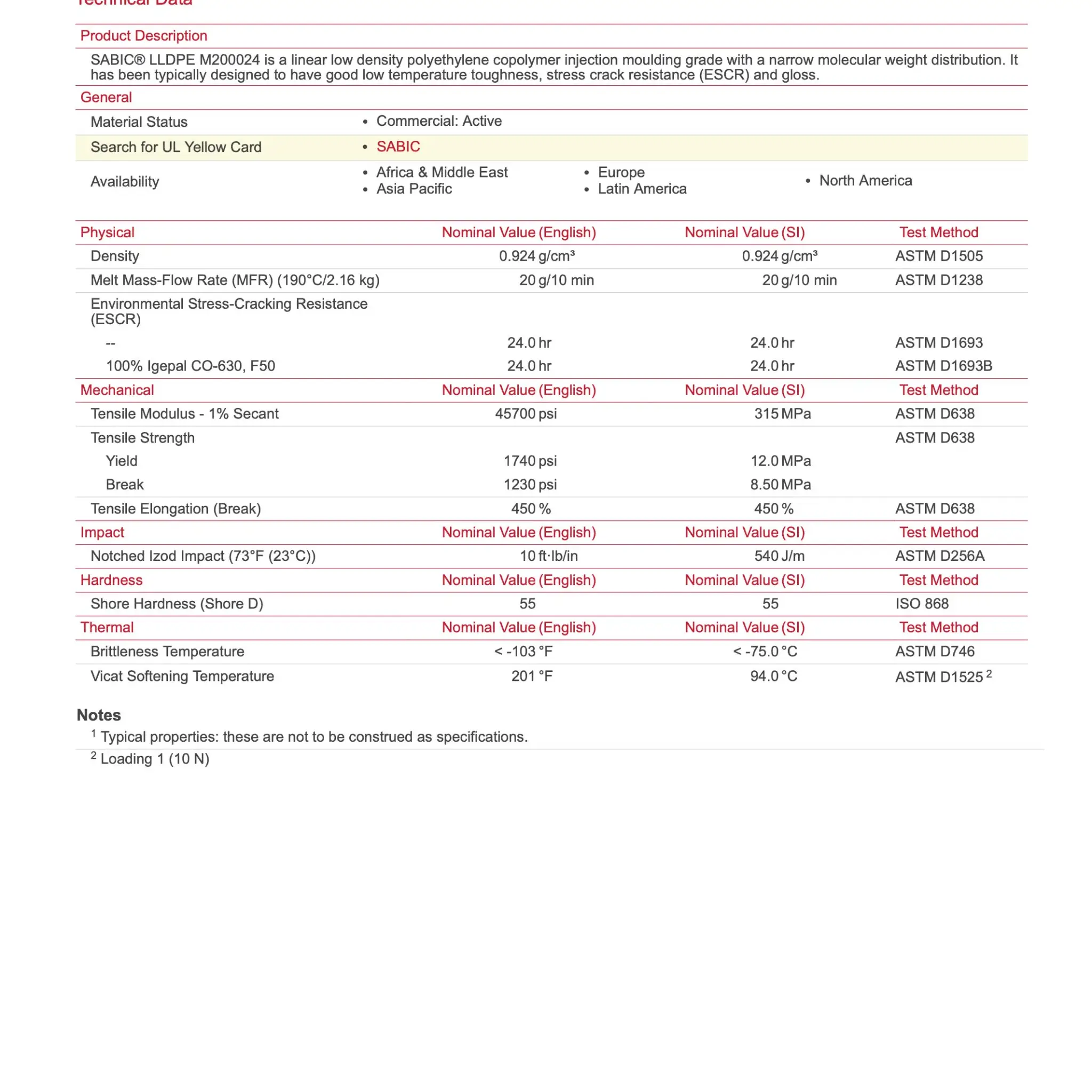

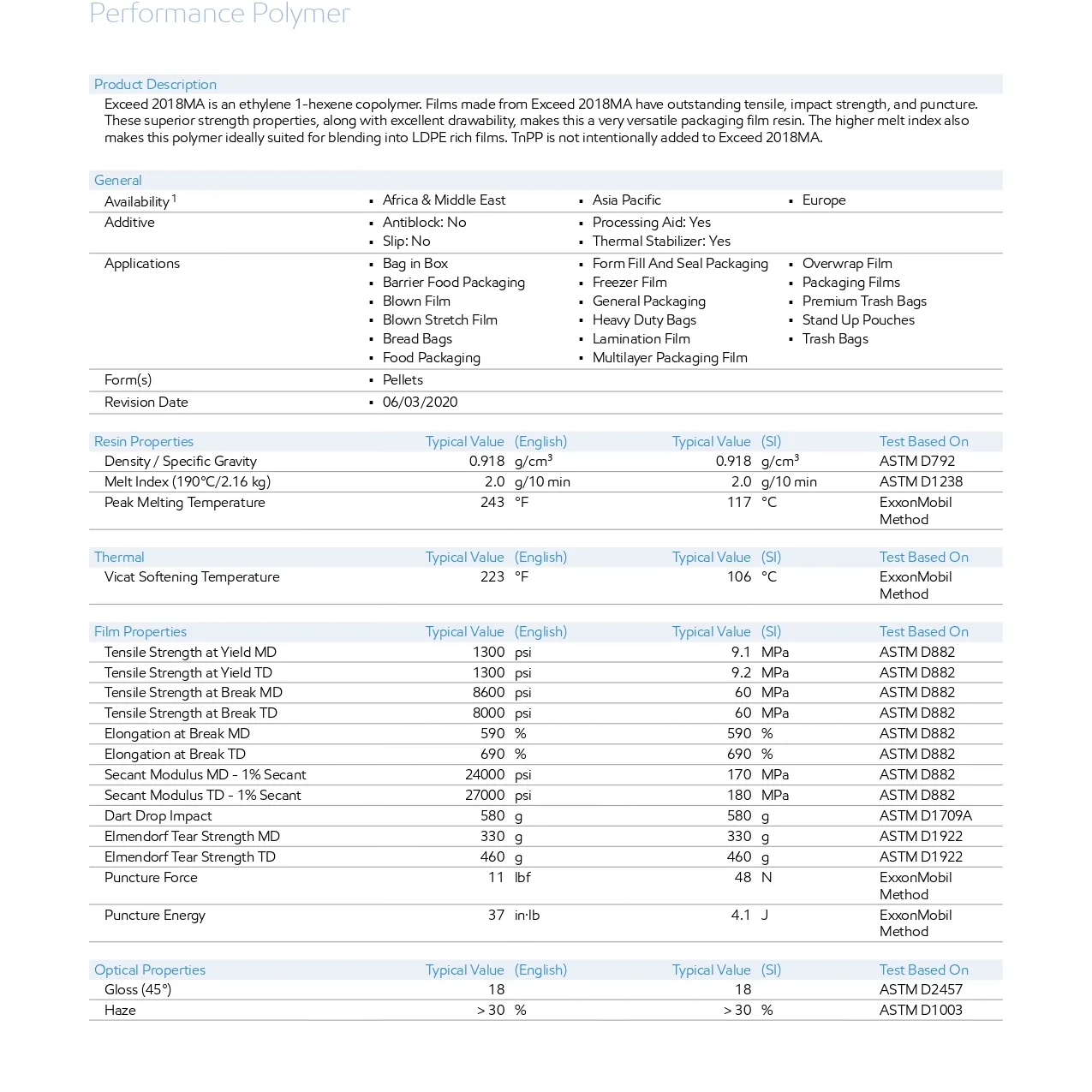

Physical Density ASTM D4883 Melt Mass-Flow Rate (MFR) (190°C/2.16 kg) ISO 1872-2

Mechanical Tensile Stress (Yield) ISO 1872-2 Tensile Strain (Break) ISO 1872-2 Flexural Modulus ISO 1872-2

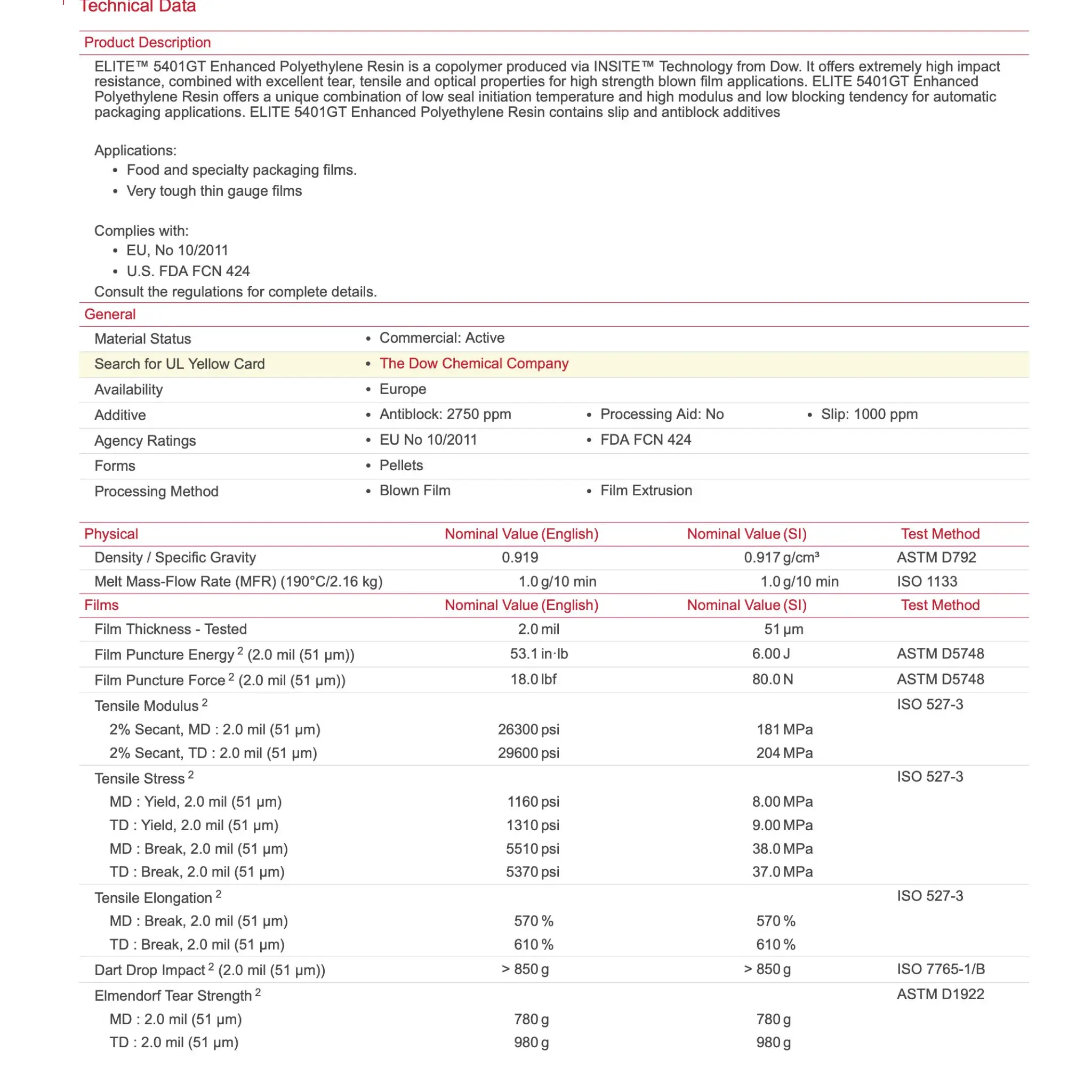

Films Film Thickness - Tested Tensile Modulus ISO 527-3 MD : 1.2 mil ISO 527-3 TD : 1.2 mil ISO 527-3 Tensile Stress ISO 527-3 MD : Break, 1.2 mil ISO 527-3 TD : Break, 1.2 mil ISO 527-3 Tensile Elongation ISO 527-3 MD : Break, 1.2 mil ISO 527-3 TD : Break, 1.2 mil ISO 527-3 Dart Drop Impact (1.2 mil) ISO 7765-1 Elmendorf Tear Strength ISO 6383-2 MD : 1.2 mil ISO 6383-2 TD : 1.2 mil ISO 6383-2

Hardness Shore Hardness (Shore D) ISO 868

Thermal Brittleness Temperature ISO 974 Vicat Softening Temperature ISO 306 Melting Temperature ISO 11357-3

Optical Haze (1.18 mil) ISO 14782

Extrusion Screw L/D Ratio Extrusion Notes

Blow up ratio: 2.0

Extruder: 40 mm, L/D=24

Die Diameter: 75mm