5401GT là loại nhựa LLDPE C8 của hãng Dow Chemical, chỉ số chảy là 1.0 g/10min, chuyên dùng làm màng đa lớp, màng stretch film, rất dai, chống đâm thủng tốt.

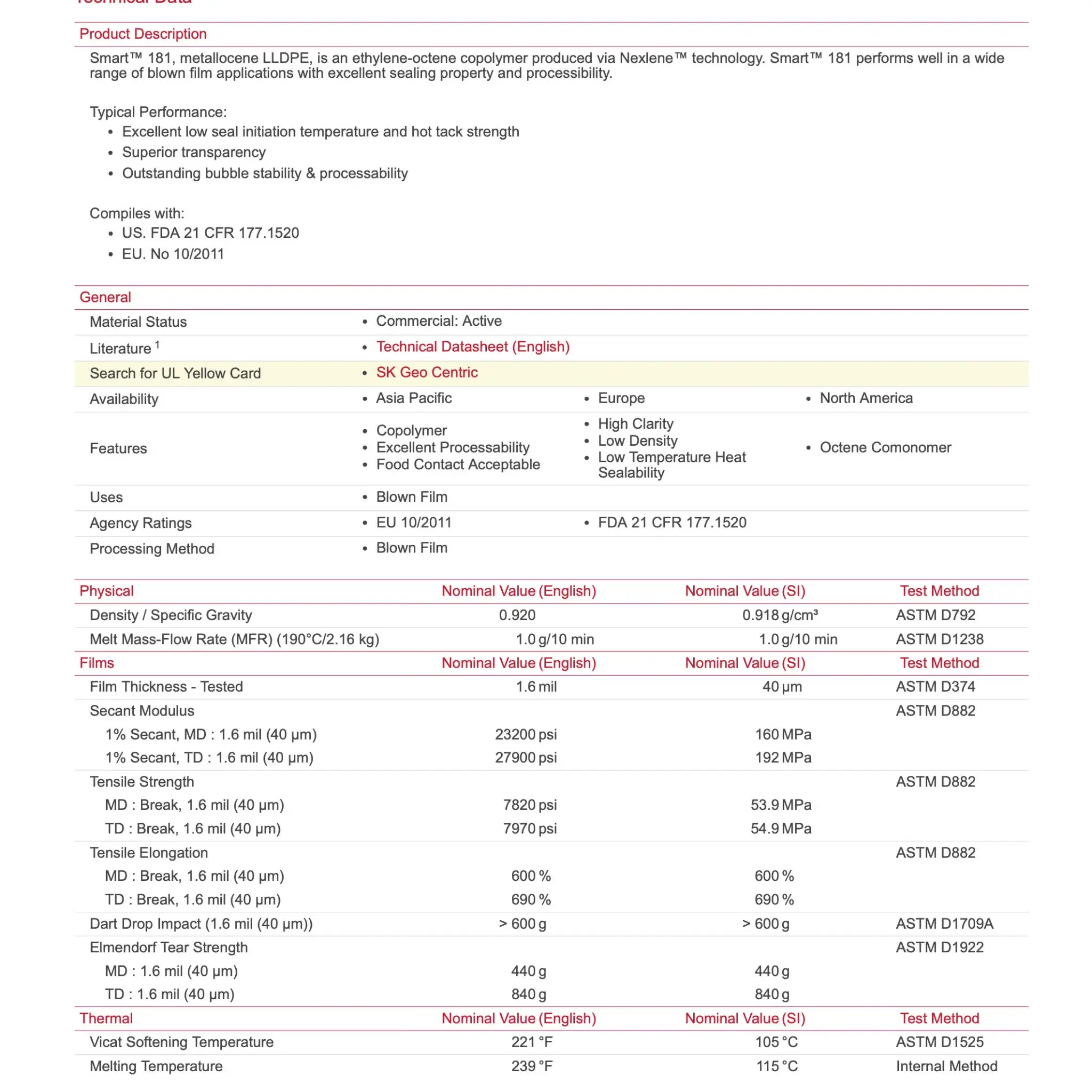

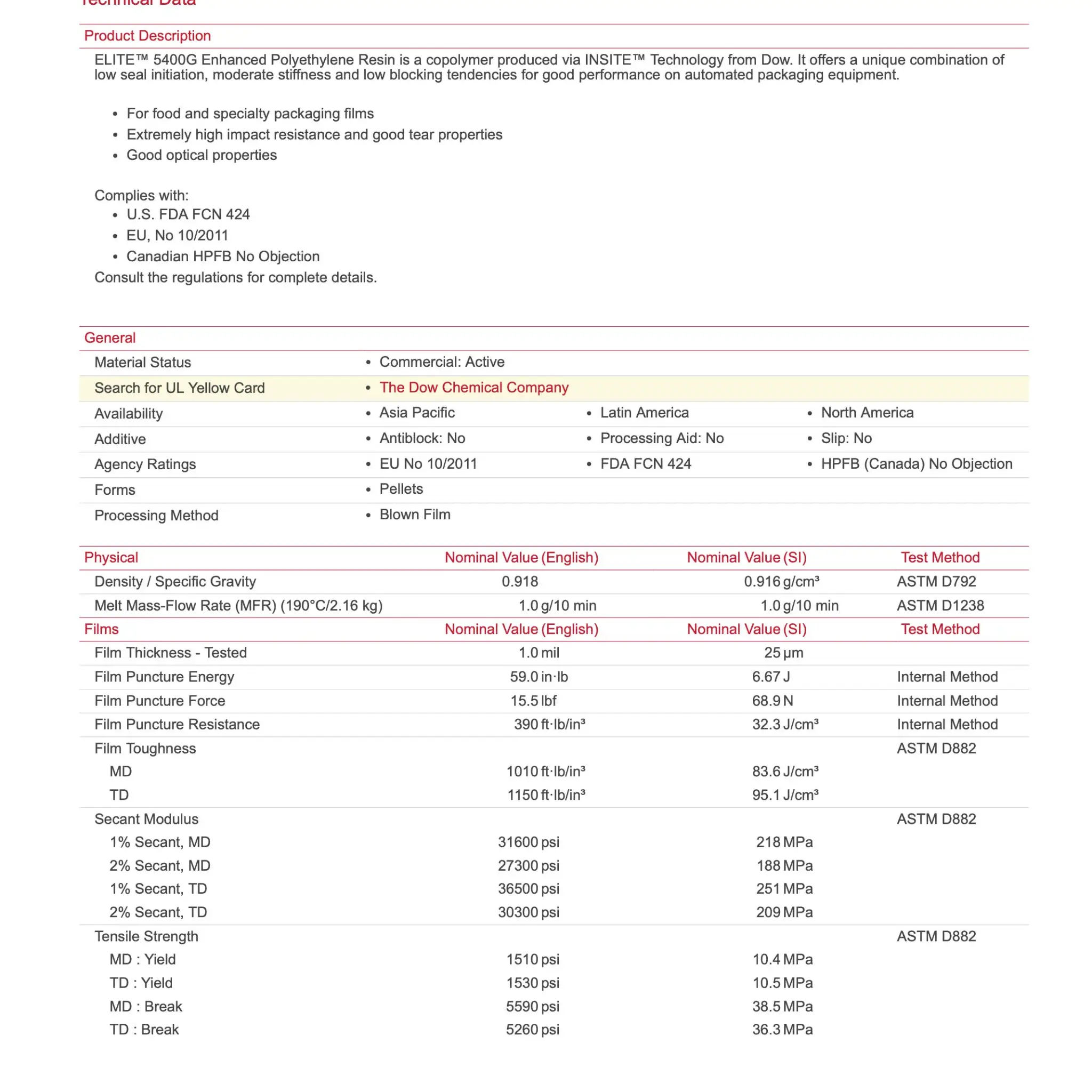

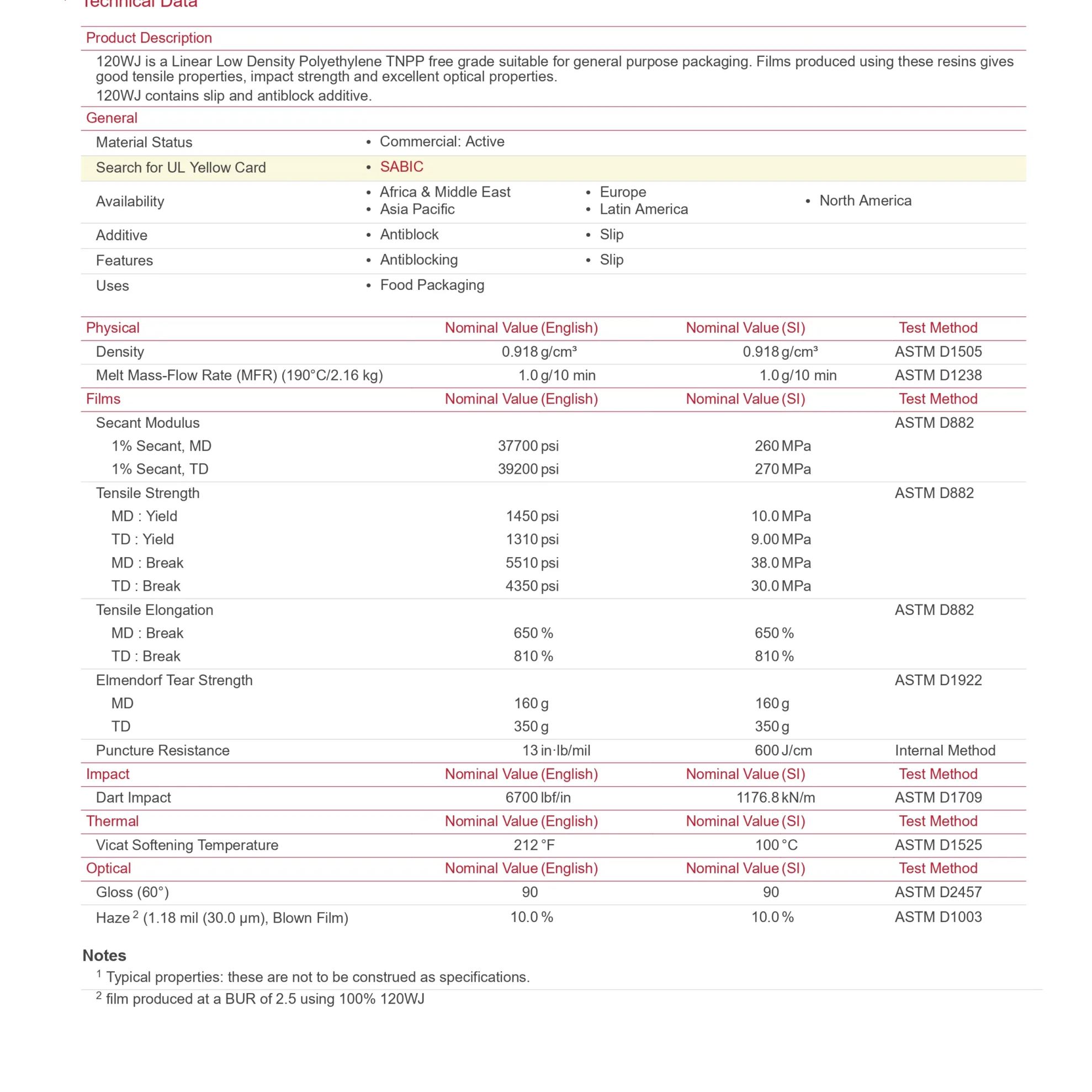

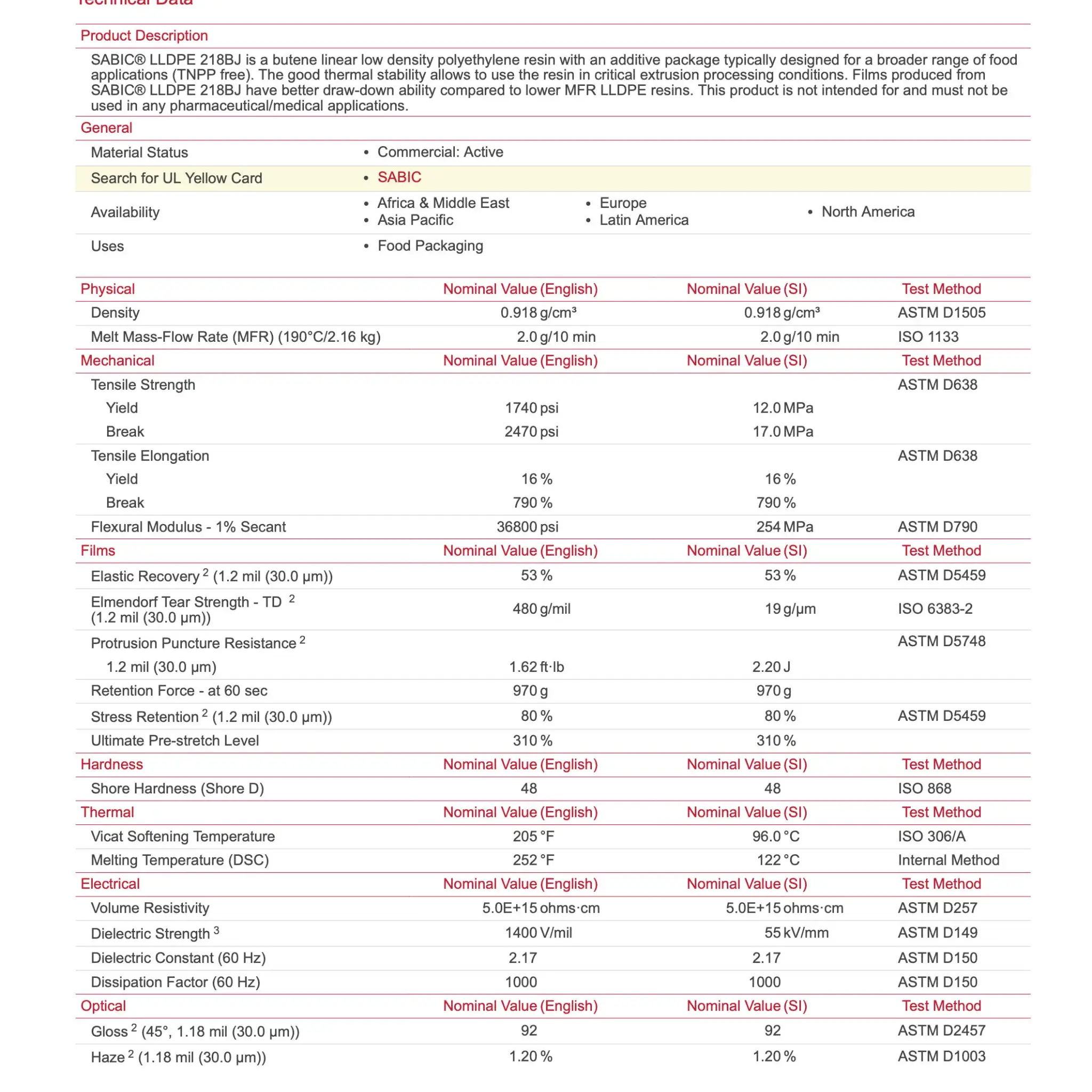

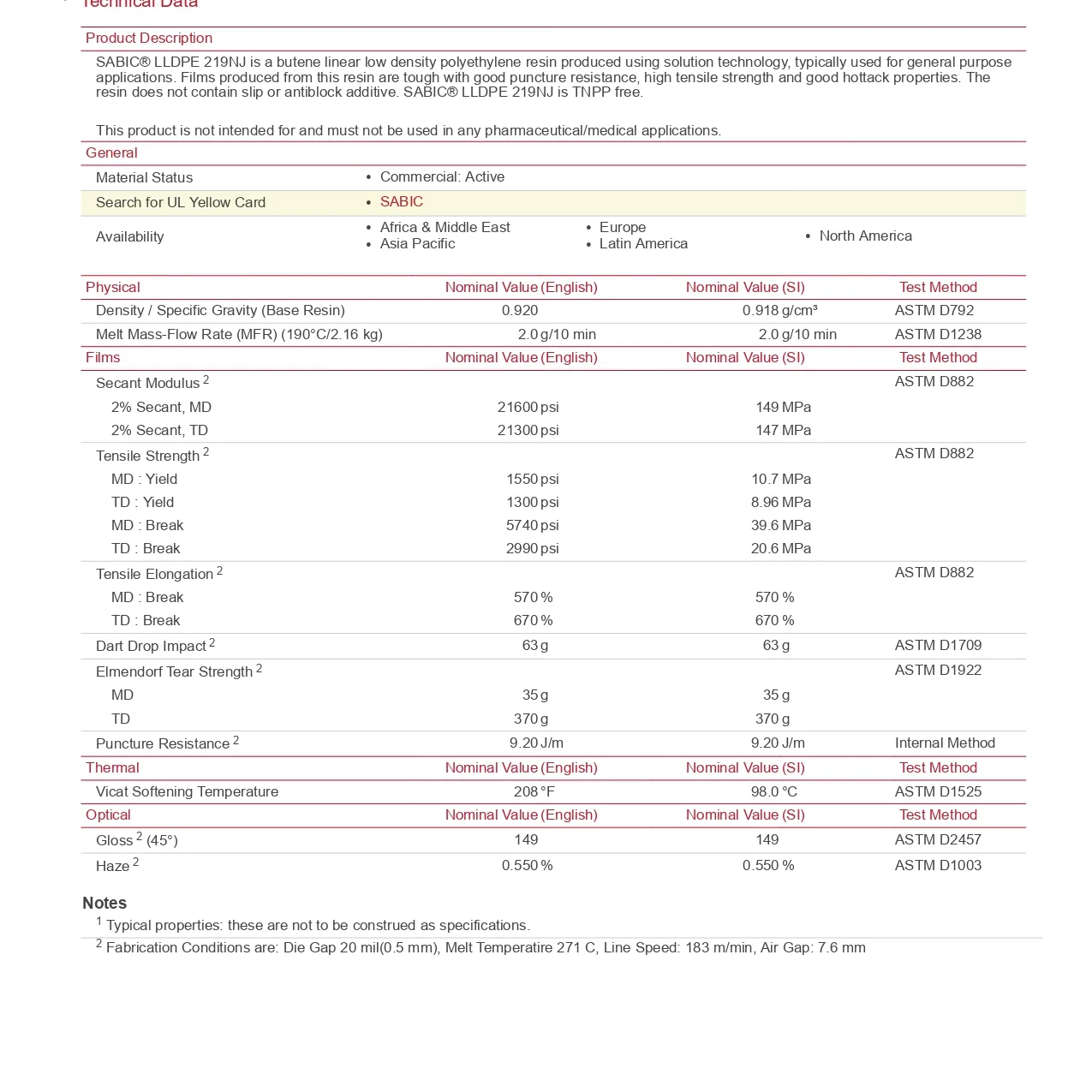

General Material Status Availability Additive Agency Ratings Forms Processing Method

Physical Density / Specific Gravity ASTM D792 Melt Mass-Flow Rate (MFR) (190°C/2.16 kg) ISO 1133

Films Film Thickness - Tested Film Puncture Energy (2.0 mil) ASTM D5748 Film Puncture Force (2.0 mil) ASTM D5748 Tensile Modulus ISO 527-3 2% Secant, MD : 2.0 mil ISO 527-3 2% Secant, TD : 2.0 mil ISO 527-3 Tensile Stress ISO 527-3 MD : Yield, 2.0 mil ISO 527-3 TD : Yield, 2.0 mil ISO 527-3 MD : Break, 2.0 mil ISO 527-3 TD : Break, 2.0 mil ISO 527-3 Tensile Elongation ISO 527-3 MD : Break, 2.0 mil ISO 527-3 TD : Break, 2.0 mil ISO 527-3 Dart Drop Impact (2.0 mil) ISO 7765-1/B Elmendorf Tear Strength ASTM D1922 MD : 2.0 mil ASTM D1922 TD : 2.0 mil ASTM D1922 Seal Initiation Temperature (2.0 mil) Internal Method

Thermal Vicat Softening Temperature ASTM D1525 Melting Temperature DSC

Optical Gloss (45°, 2.01 mil) ASTM D2457 Haze (2.01 mil) ISO 14782

Extrusion Melt Temperature Extrusion Notes