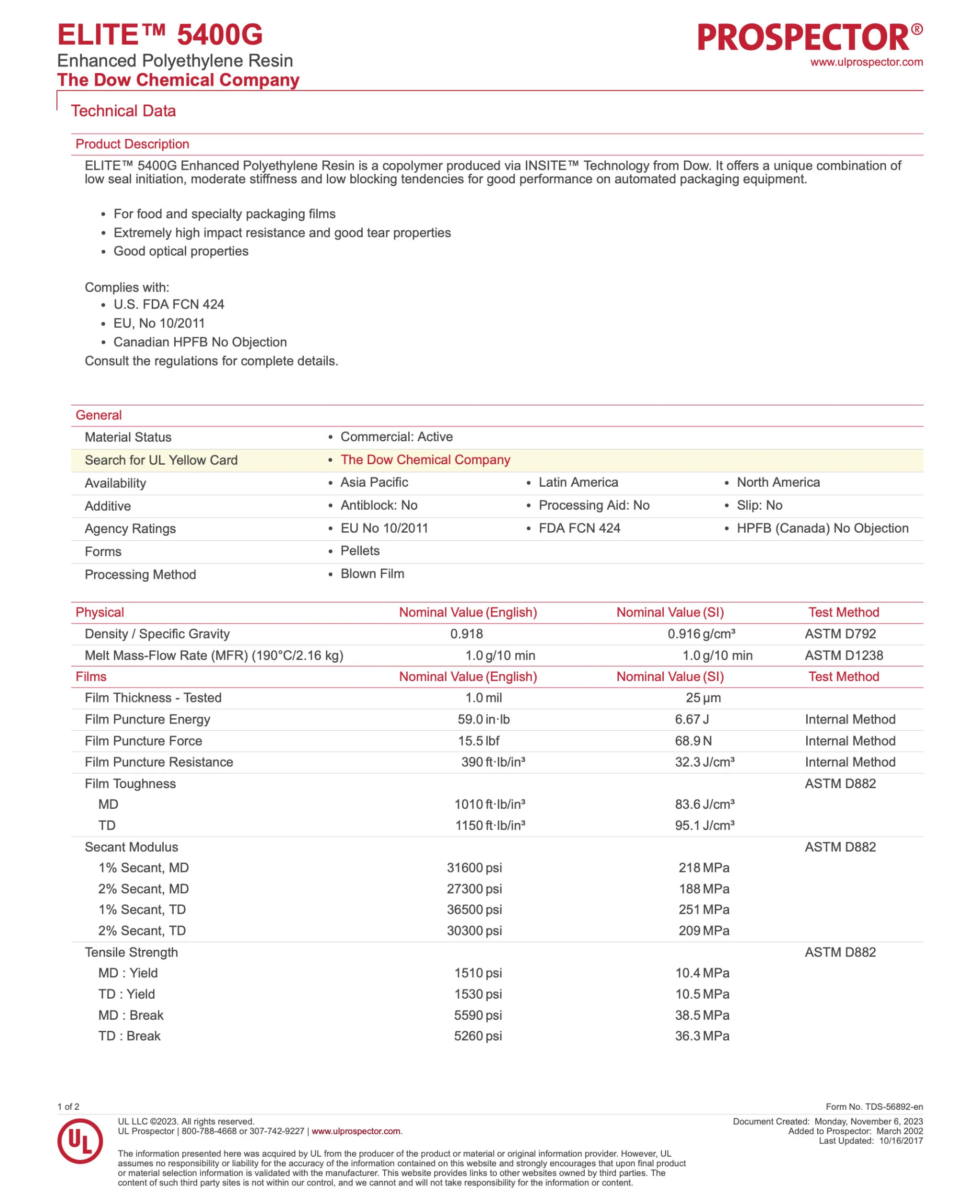

5400G là loại nhựa LLDPE C8 của hãng Dow Chemical, chỉ số chảy là 1.0 g/10min, chuyên dùng làm màng đa lớp, màng stretch film, rất dai, chống đâm thủng tốt.

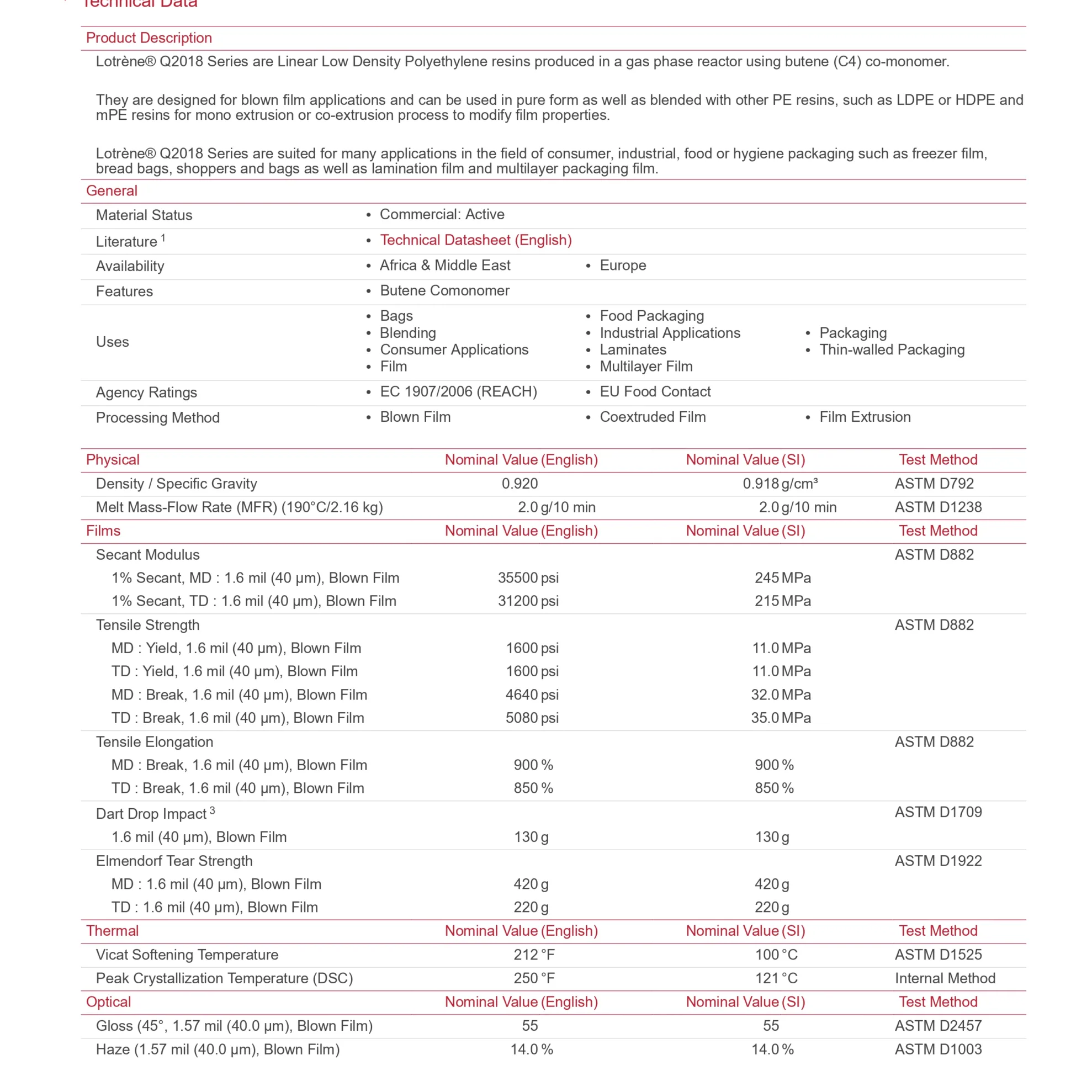

General Material Status Availability Additive Agency Ratings Forms Processing Method

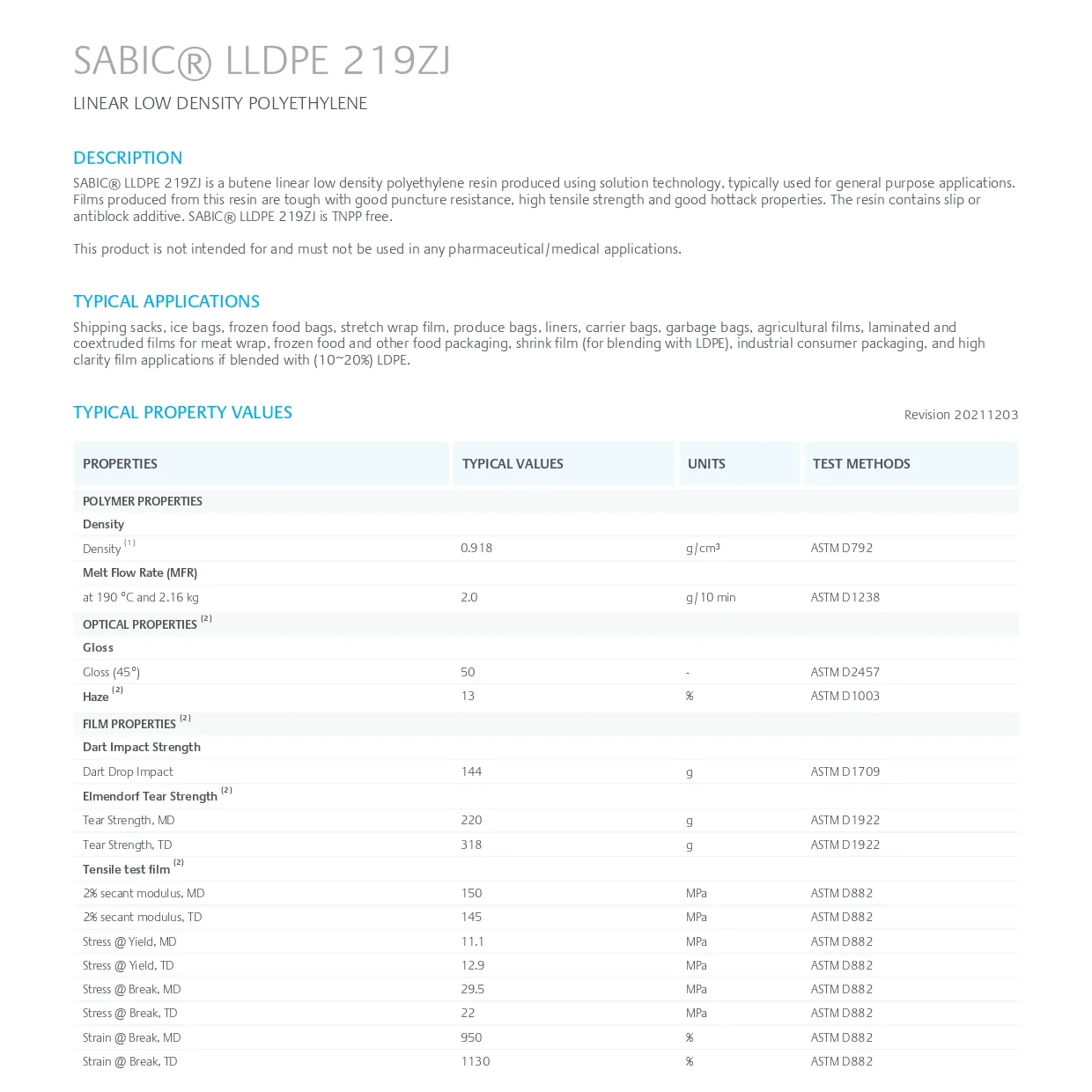

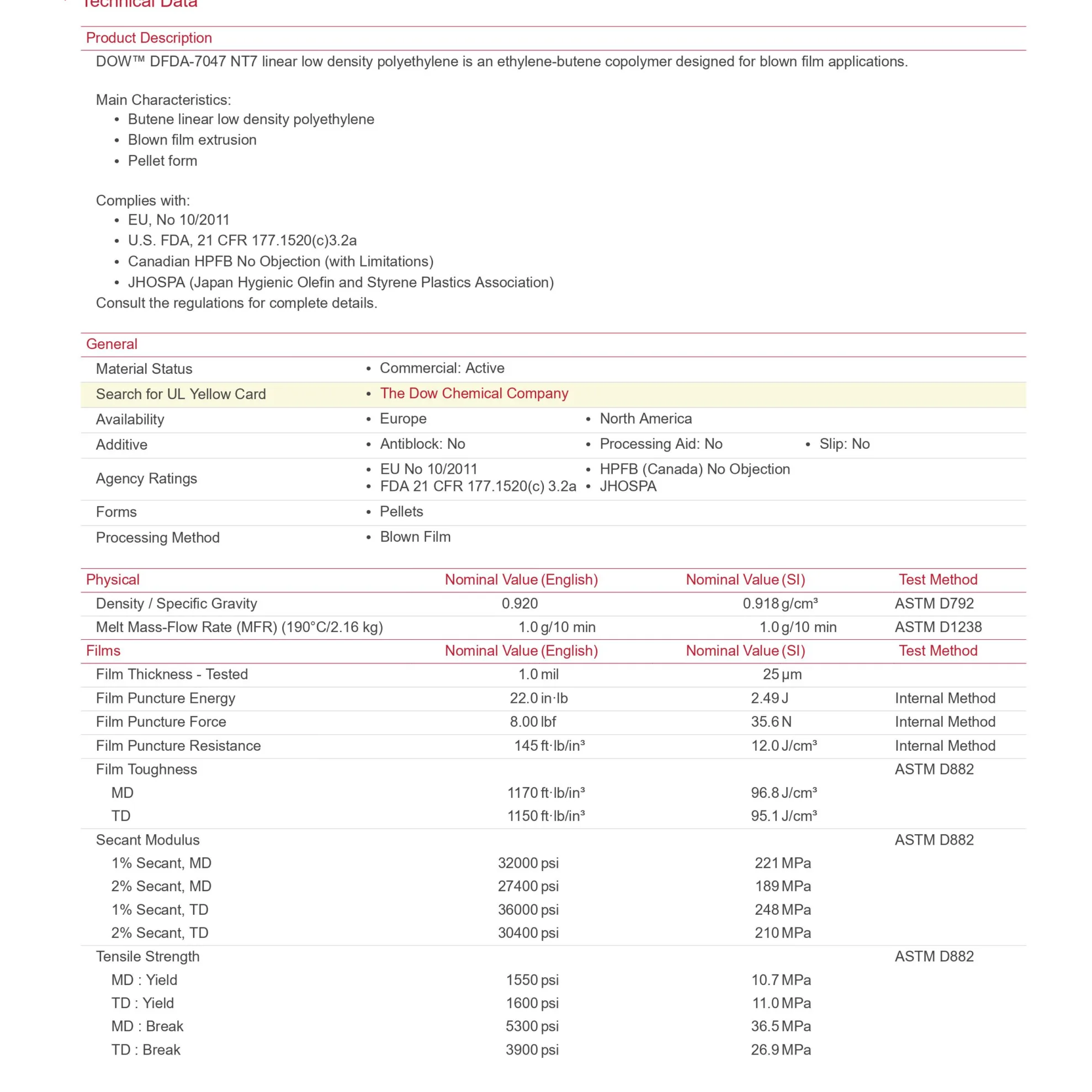

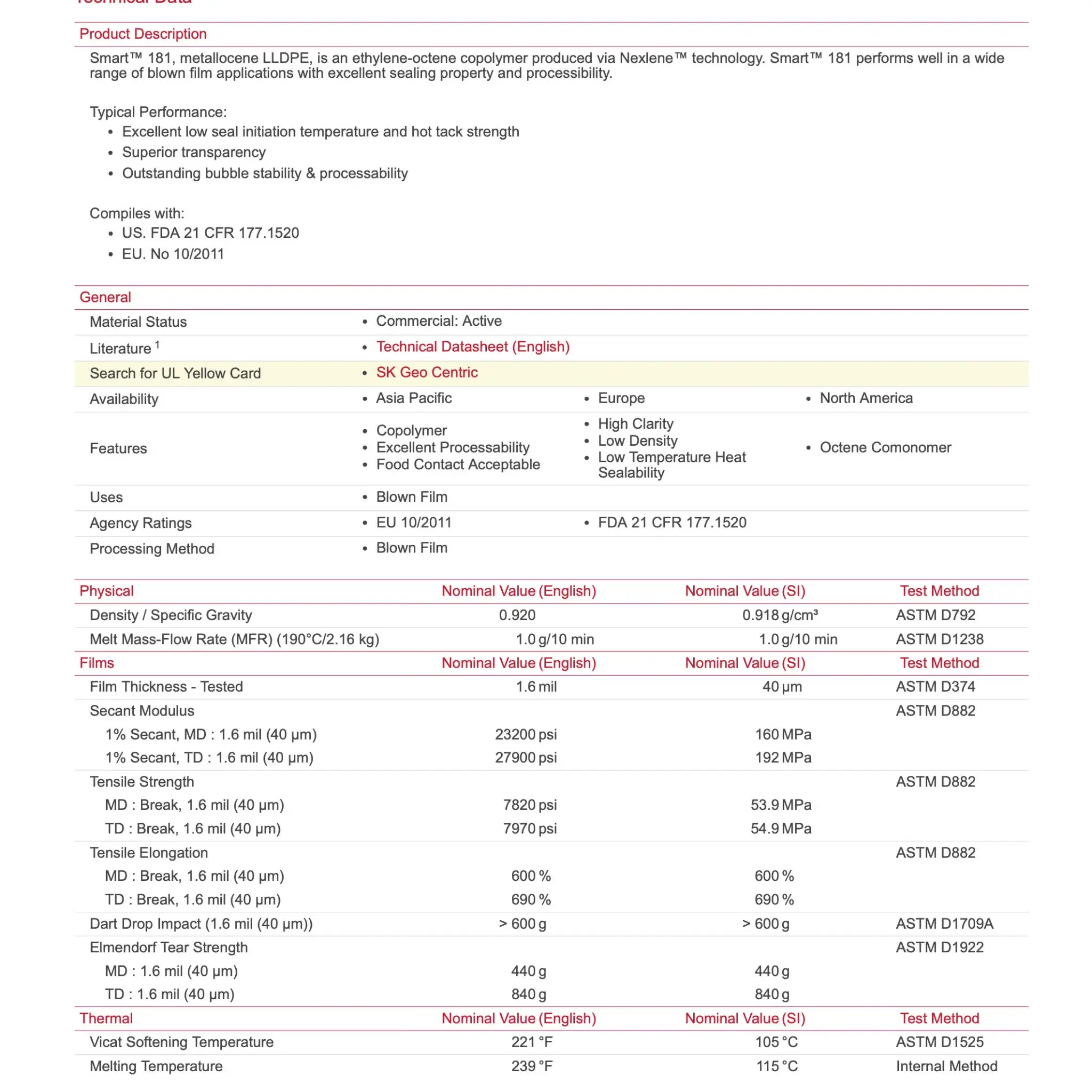

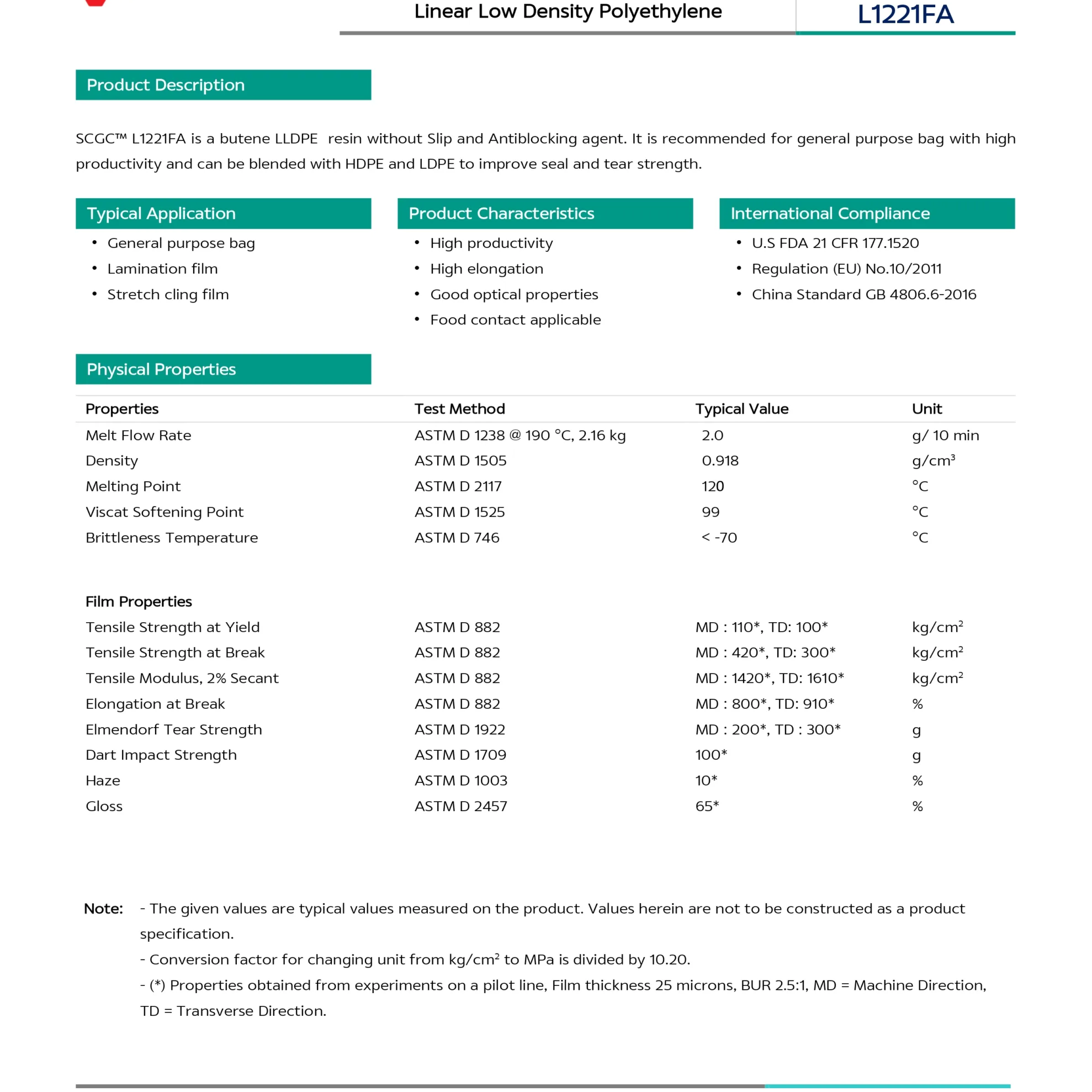

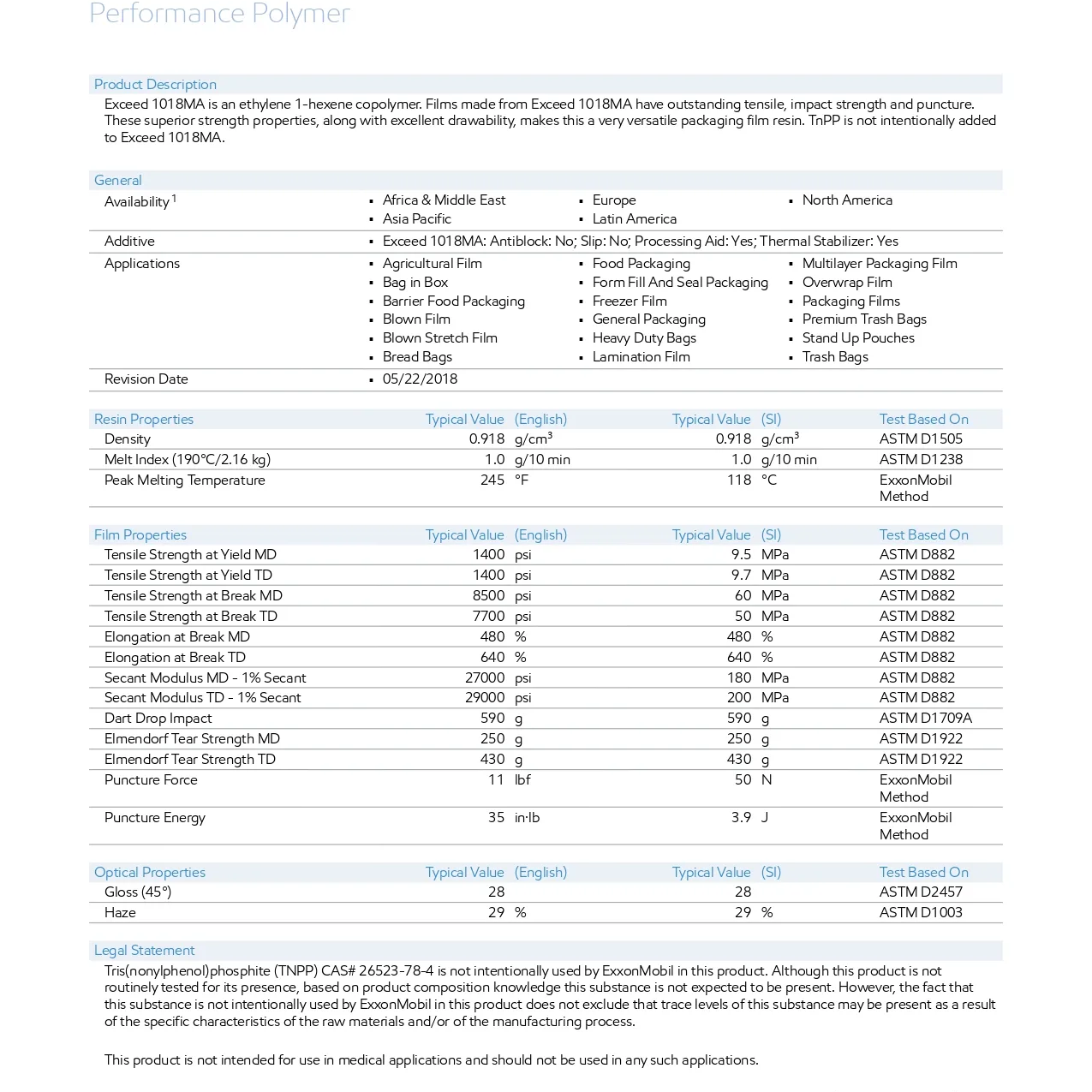

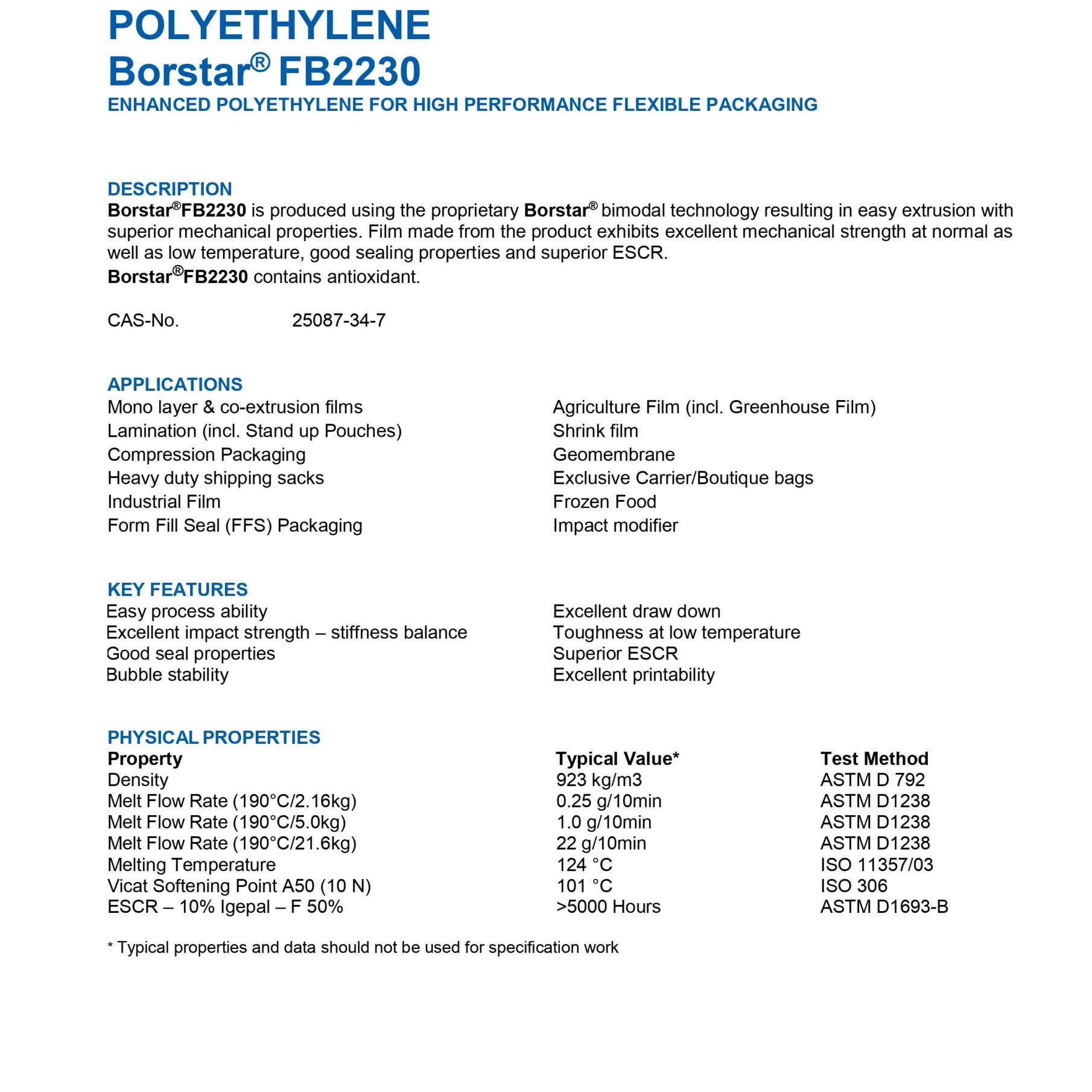

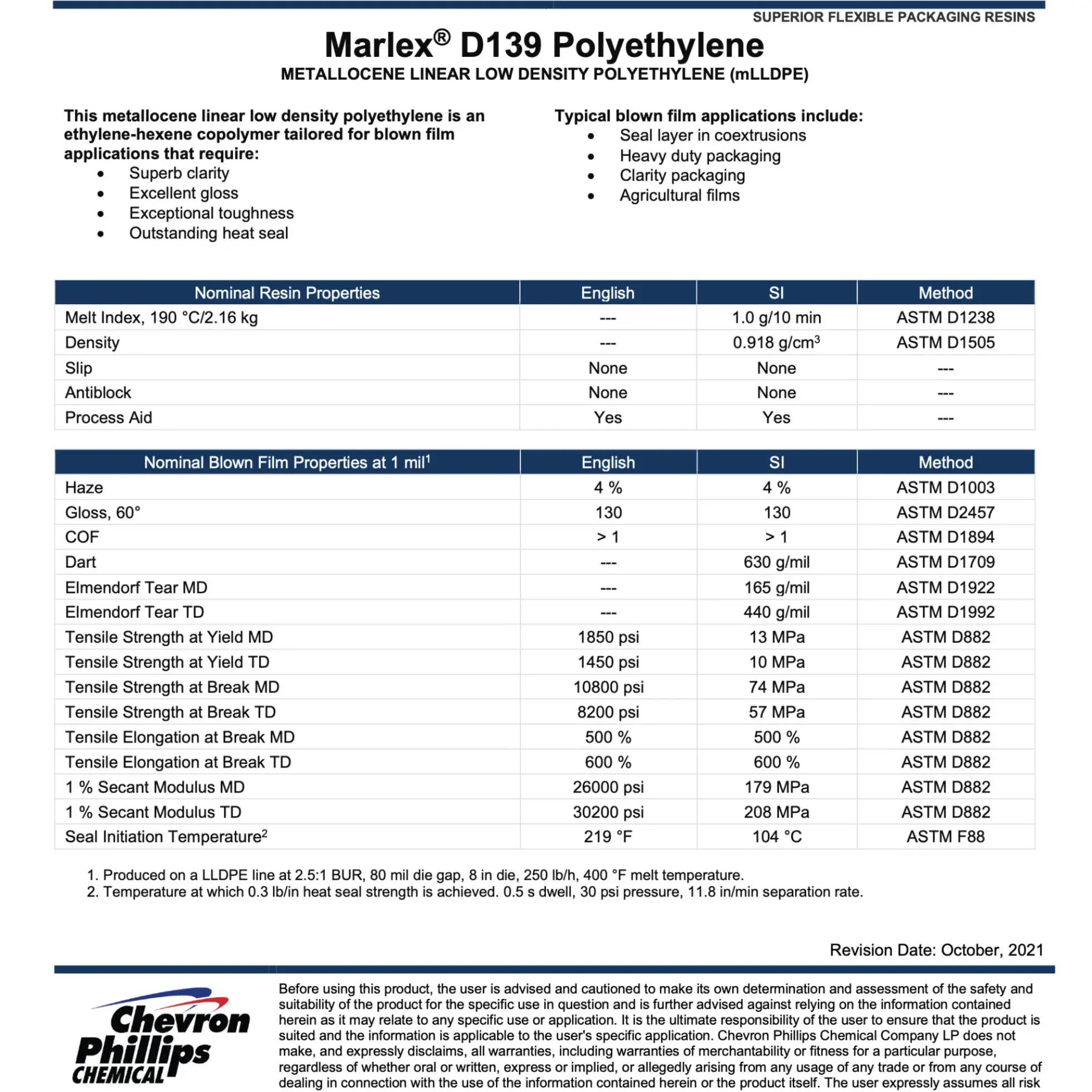

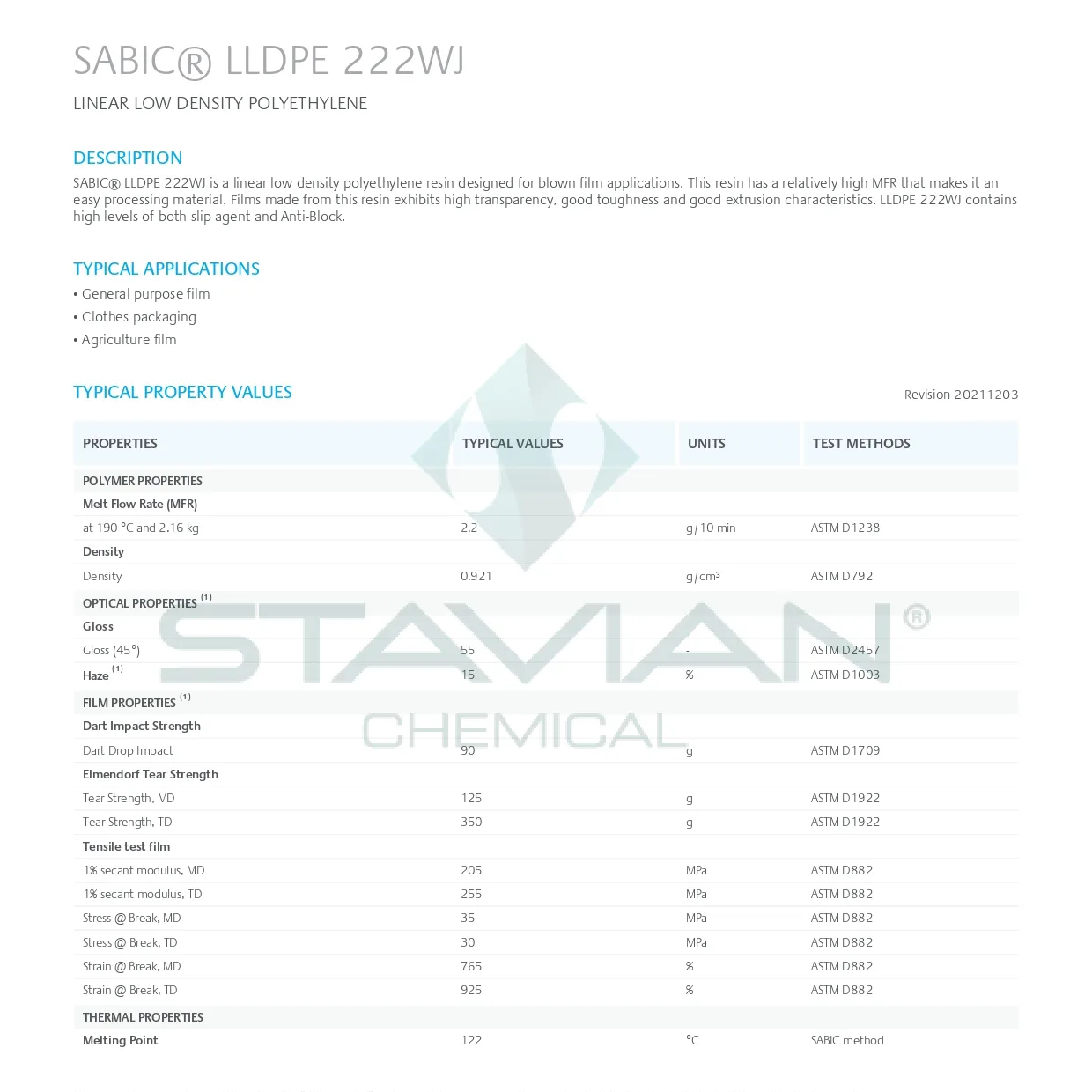

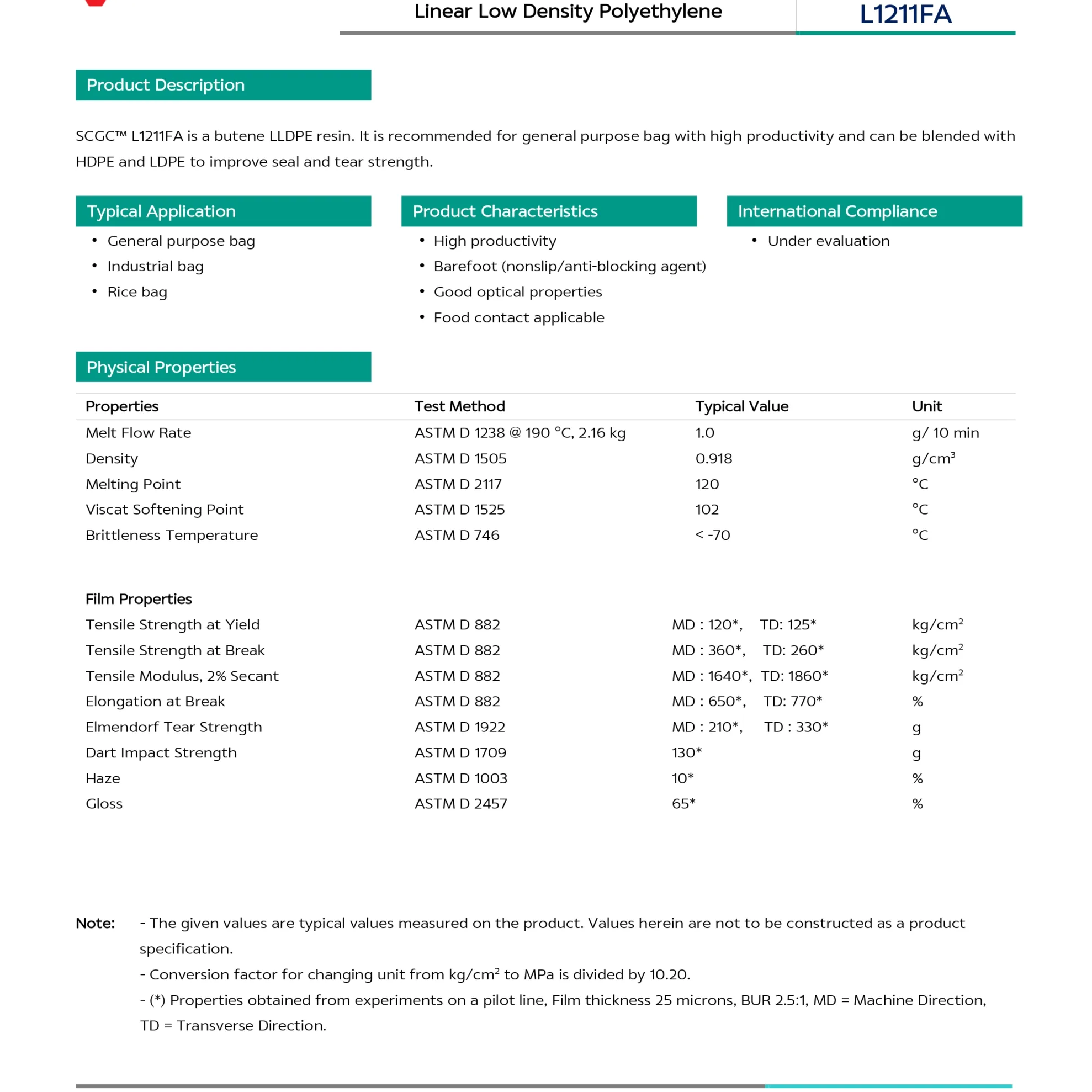

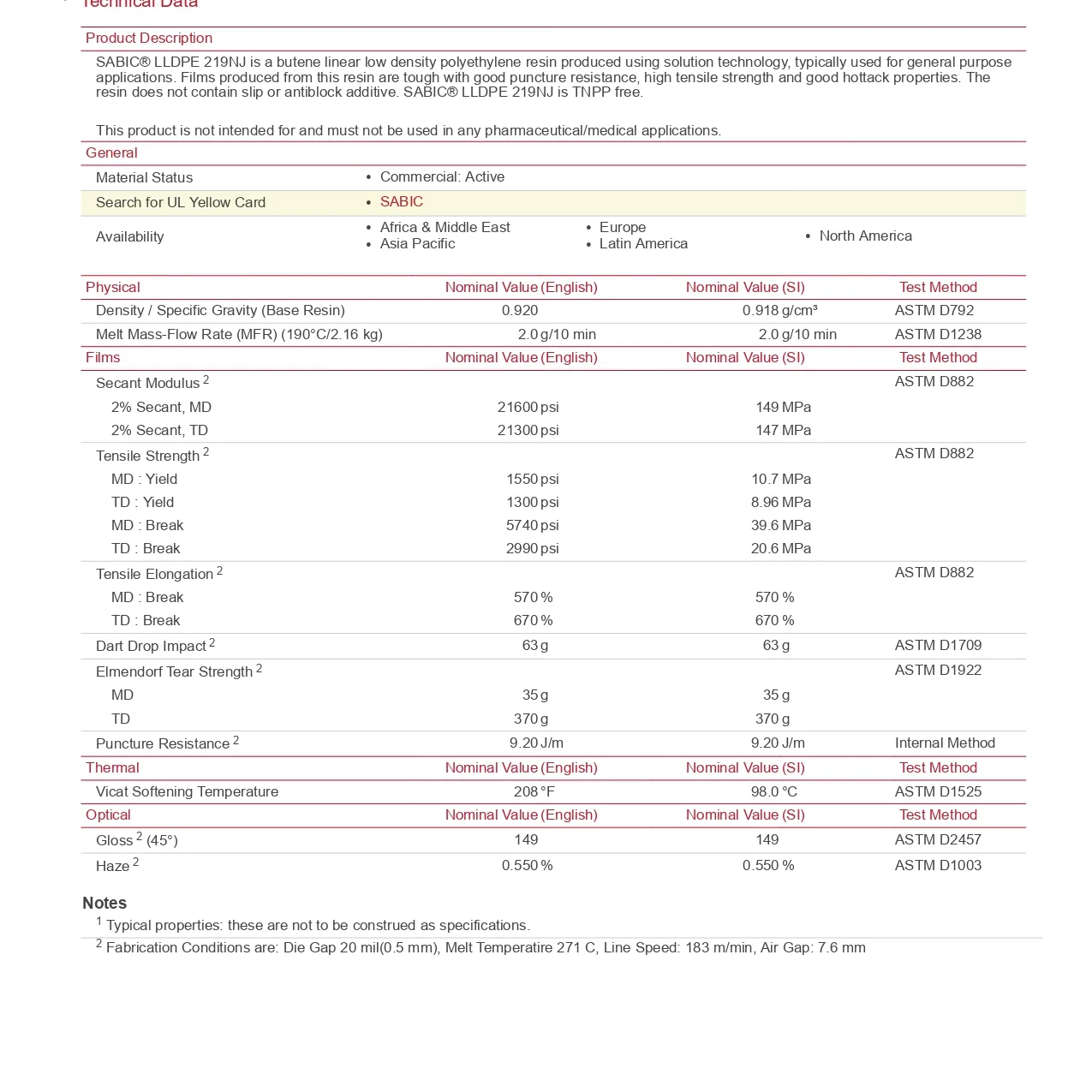

Physical Density / Specific Gravity ASTM D792 Melt Mass-Flow Rate (MFR) (190°C/2.16 kg) ASTM D1238

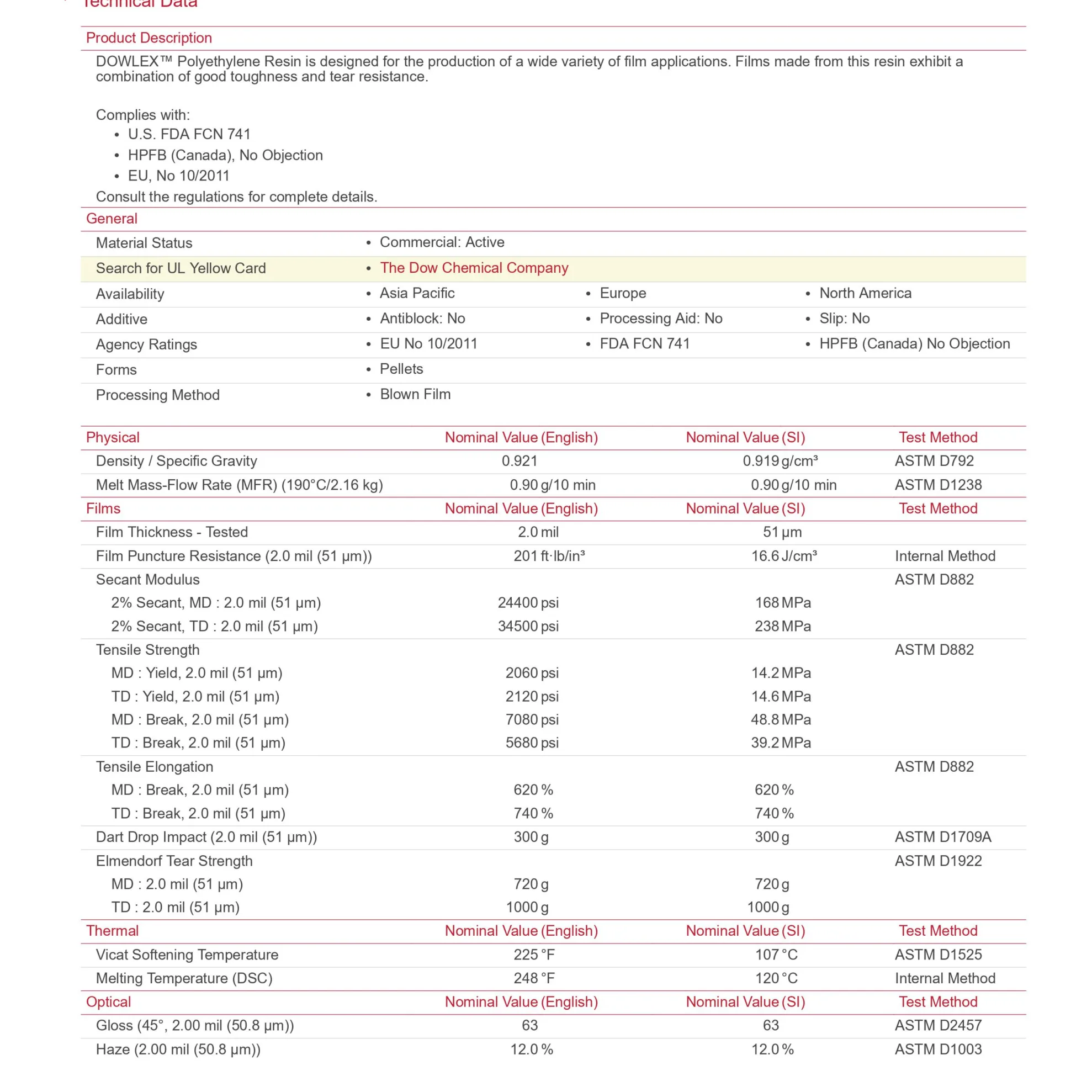

Films Film Thickness - Tested Film Puncture Energy Internal Method Film Puncture Force Internal Method Film Puncture Resistance Internal Method Film Toughness ASTM D882 MD ASTM D882 TD ASTM D882 Secant Modulus ASTM D882 1% Secant, MD ASTM D882 2% Secant, MD ASTM D882 1% Secant, TD ASTM D882 2% Secant, TD ASTM D882 Tensile Strength ASTM D882 MD : Yield ASTM D882 TD : Yield ASTM D882 MD : Break ASTM D882 TD : Break ASTM D882 Tensile Elongation ASTM D882 MD : Break ASTM D882 TD : Break ASTM D882 Dart Drop Impact ASTM D1709A Elmendorf Tear Strength ASTM D1922 MD ASTM D1922 TD ASTM D1922

Thermal Vicat Softening Temperature ASTM D1525 Melting Temperature (DSC) Internal Method

Optical Gloss (45°) ASTM D2457 Haze ASTM D1003

Extrusion Notes