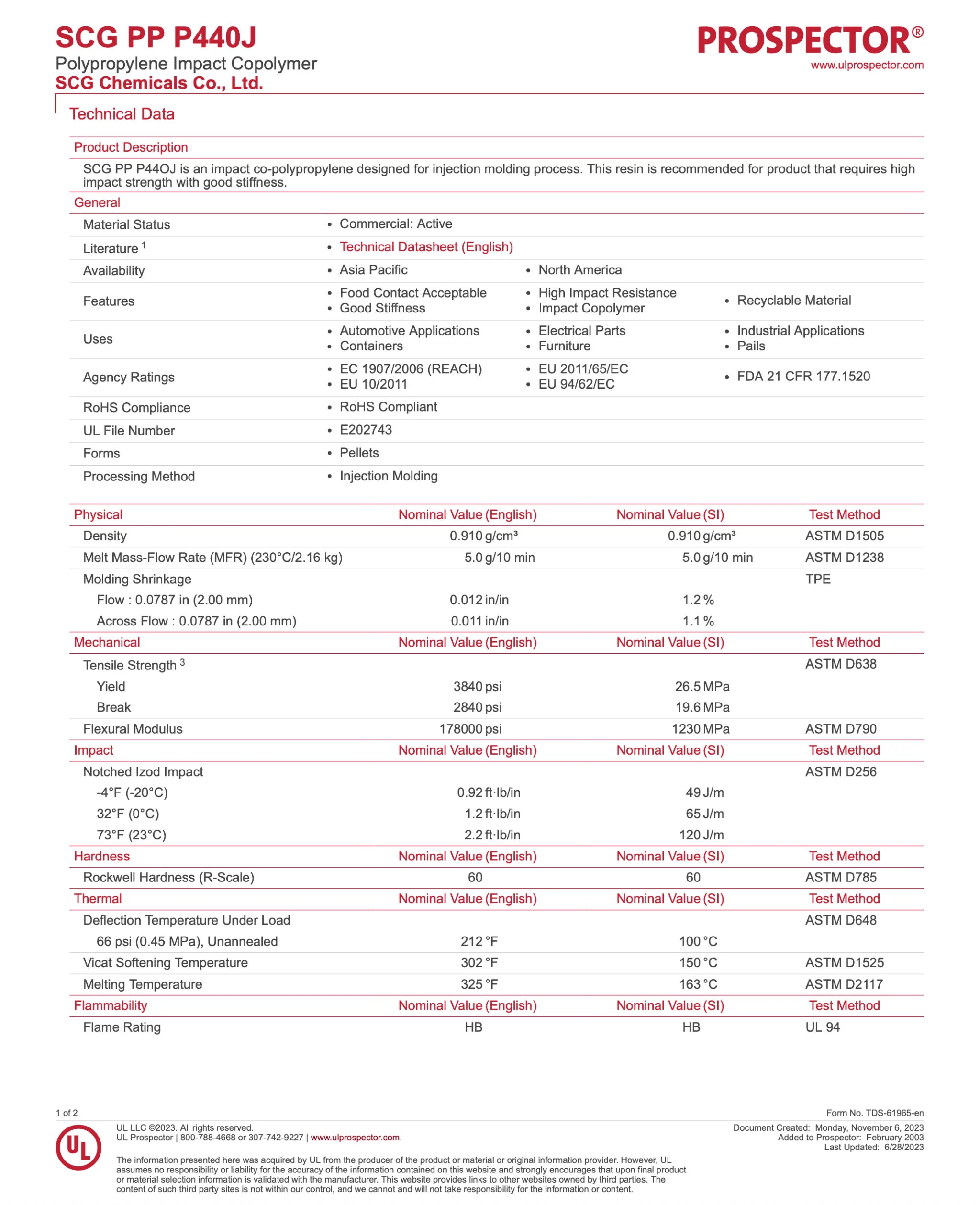

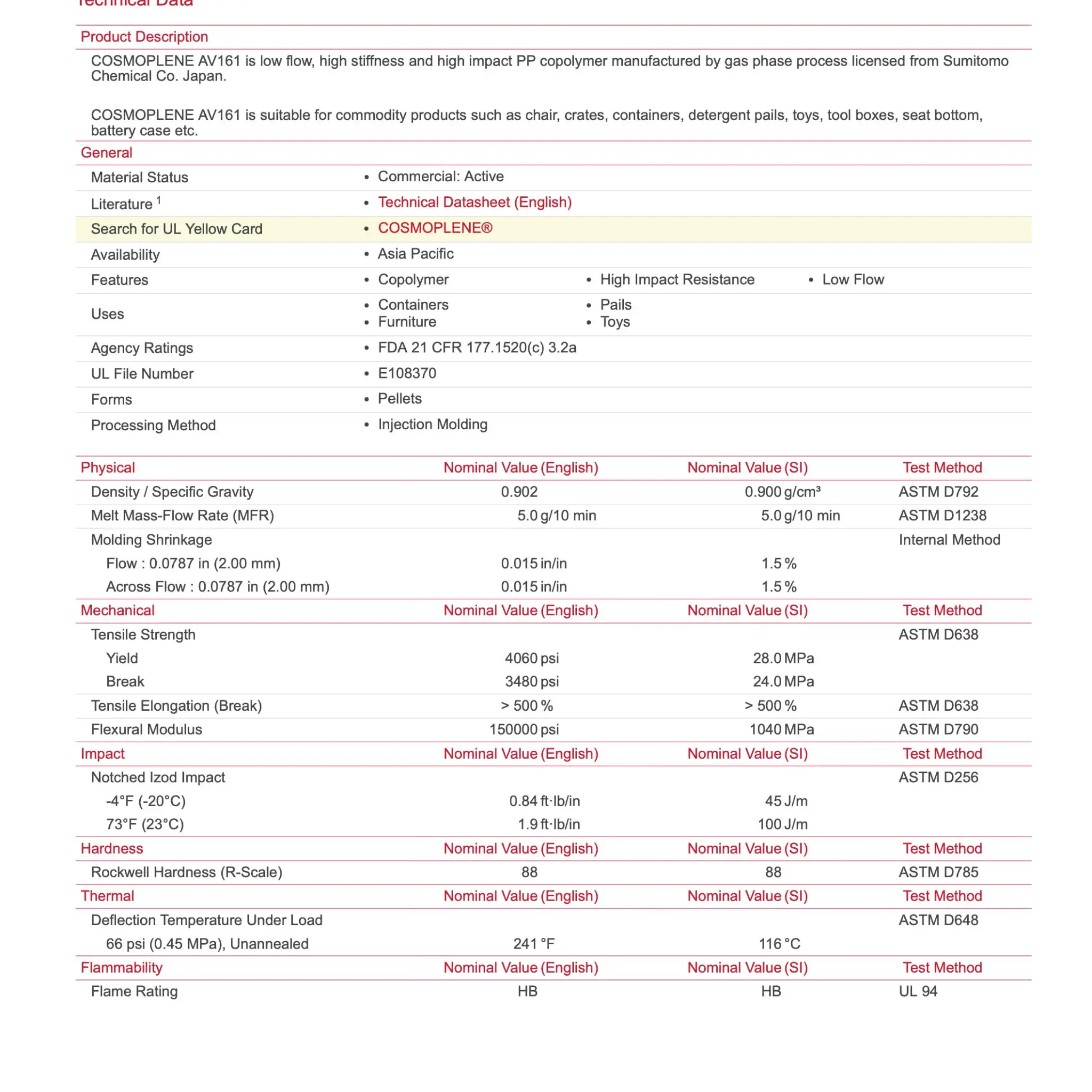

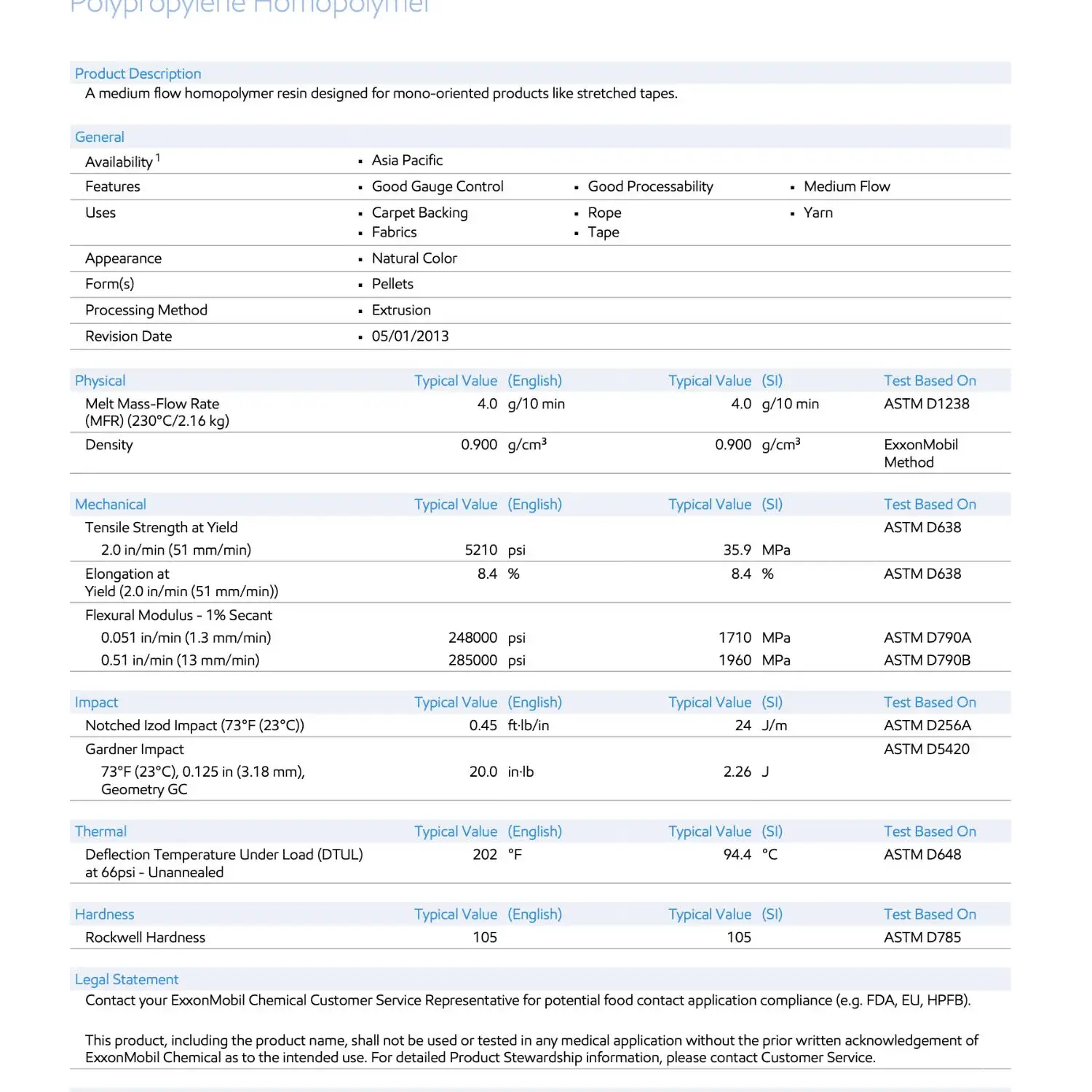

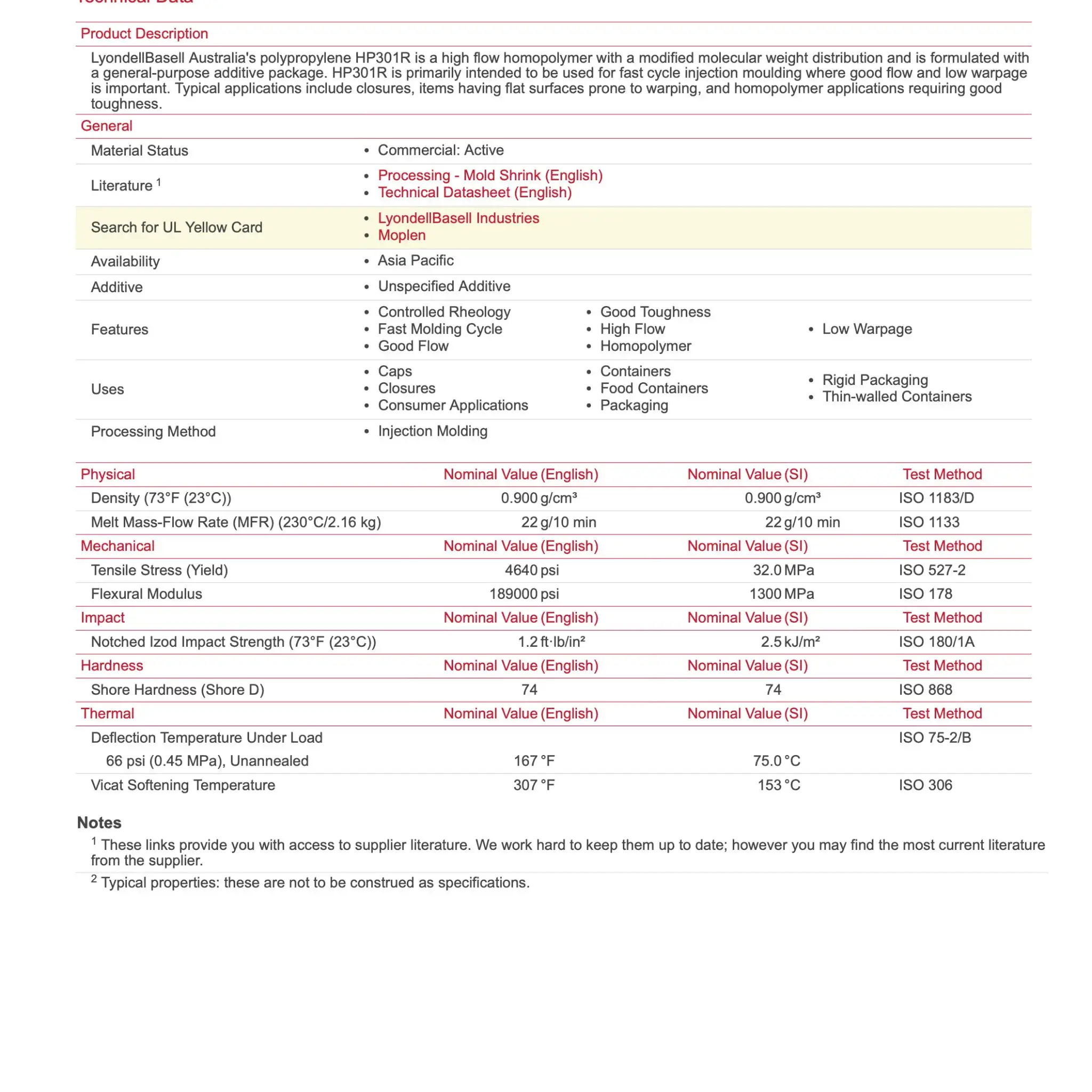

SCG PP P44OJ là co-polypropylene tác động được thiết kế cho quy trình ép phun. Loại nhựa này được khuyên dùng cho các sản phẩm yêu cầu độ bền va đập cao với độ cứng tốt.

General

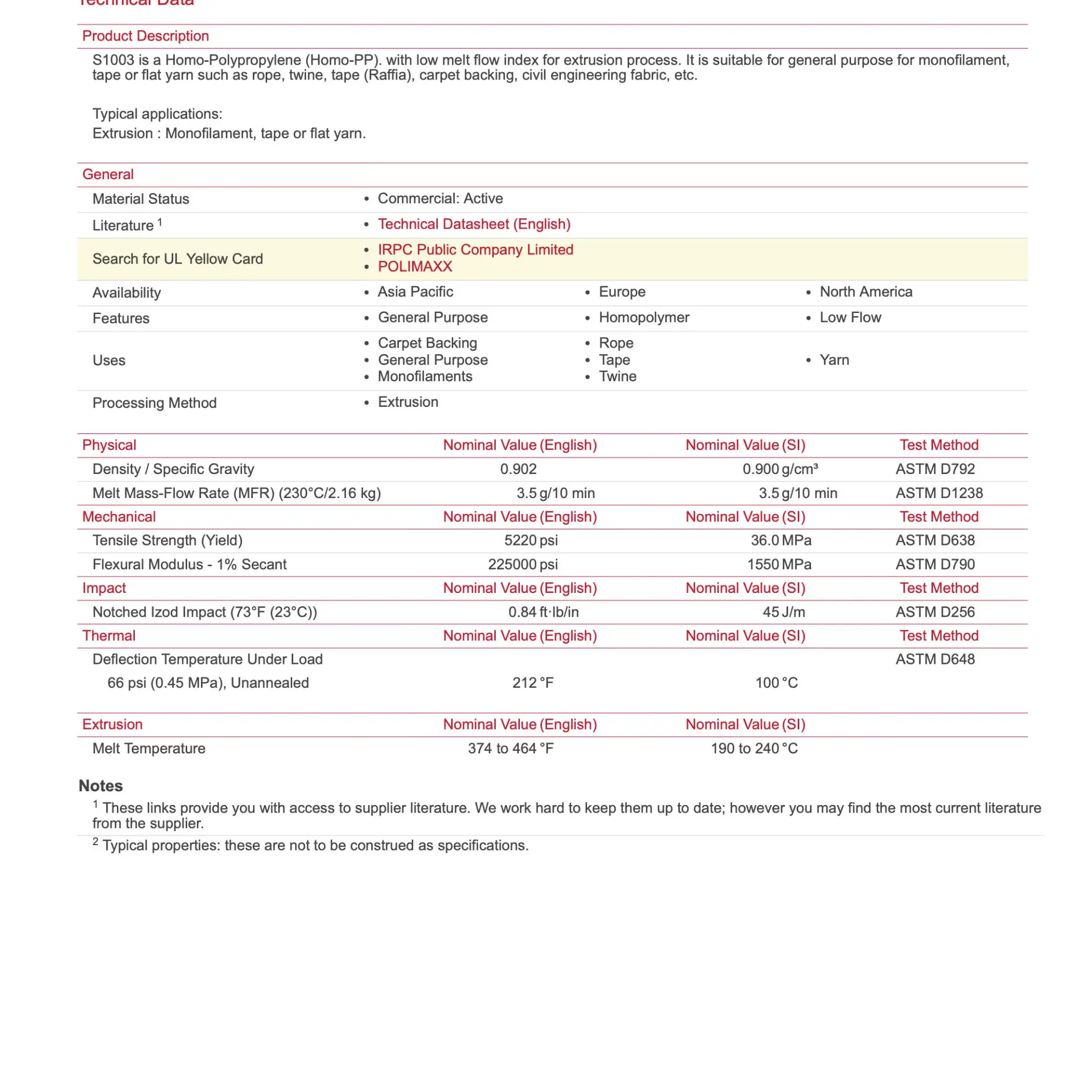

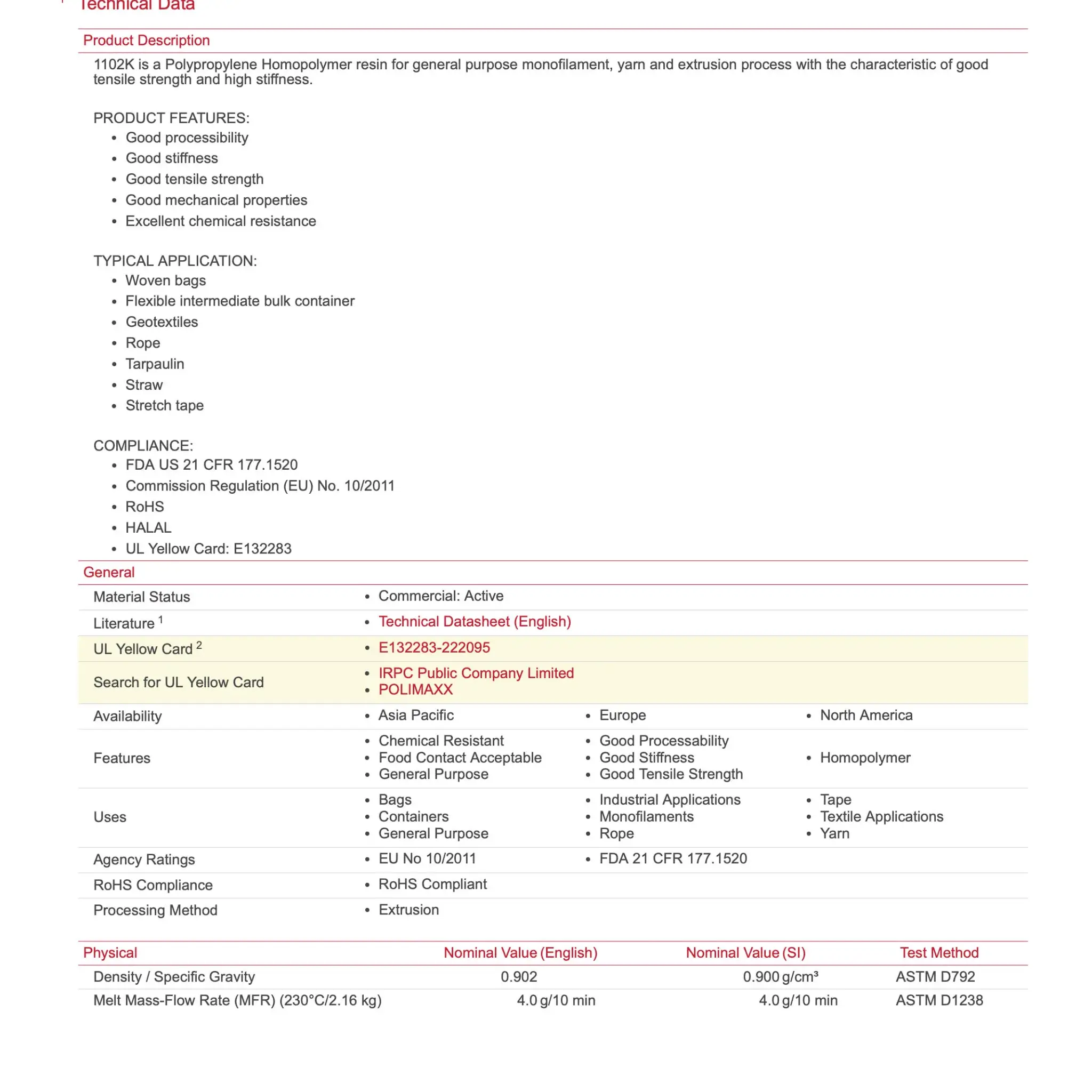

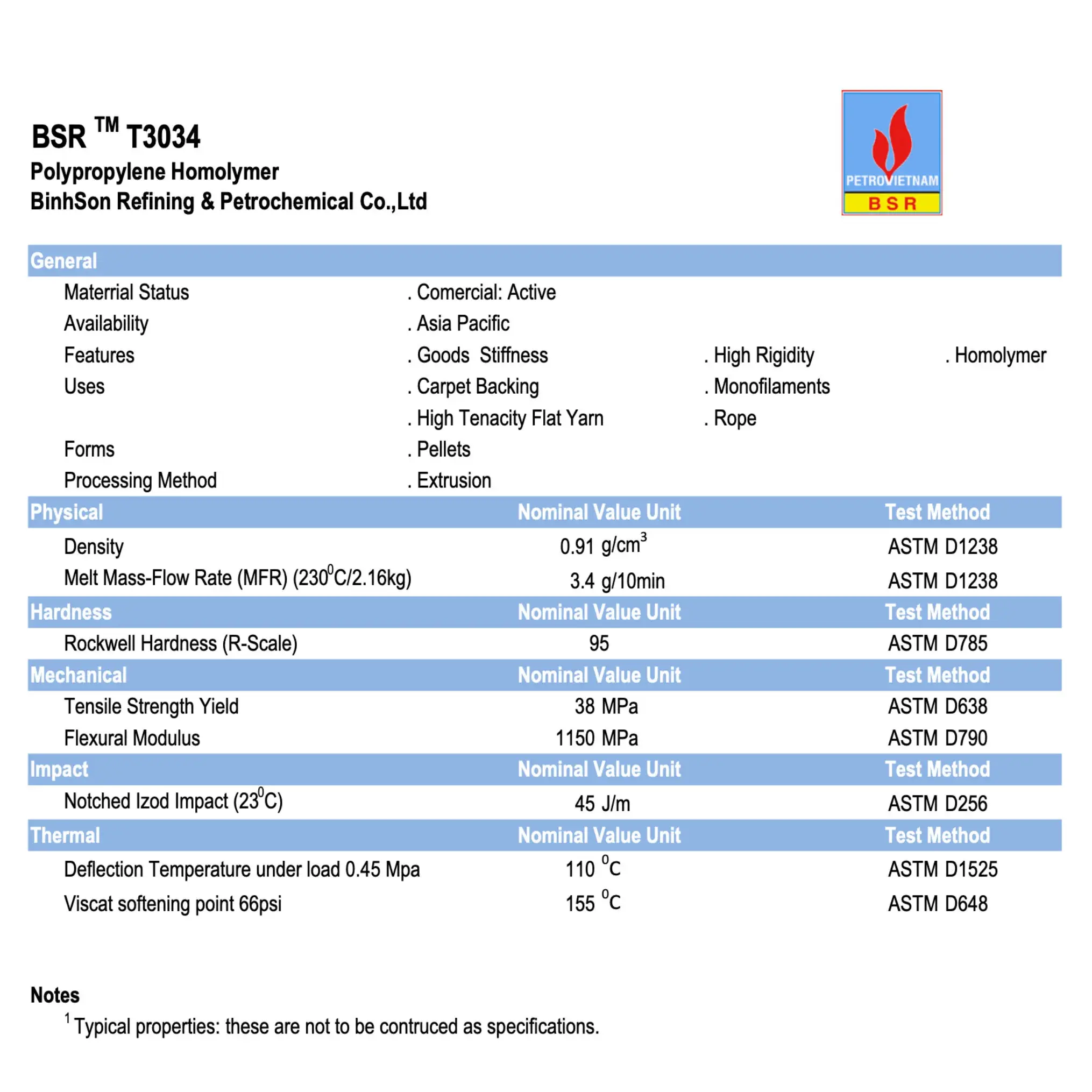

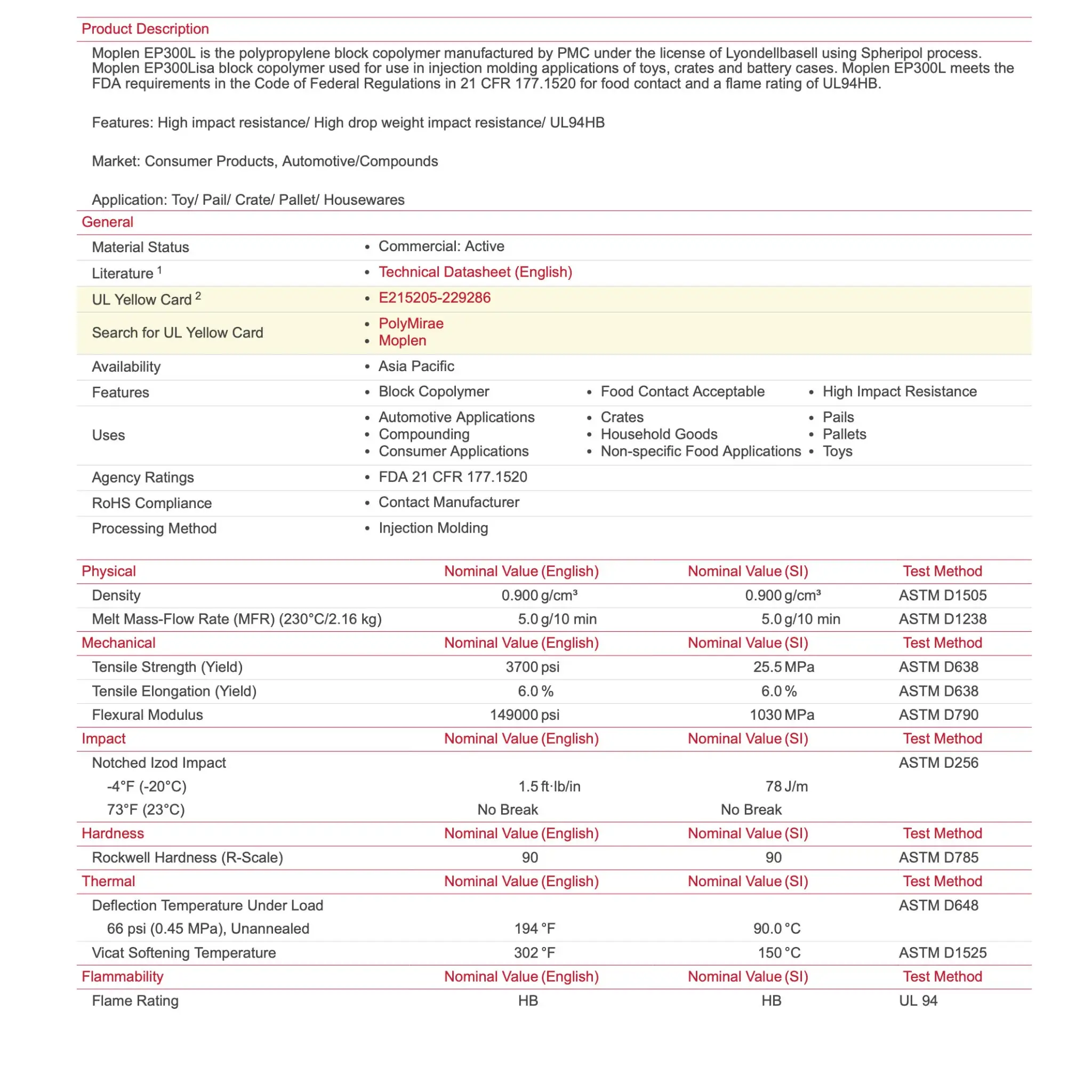

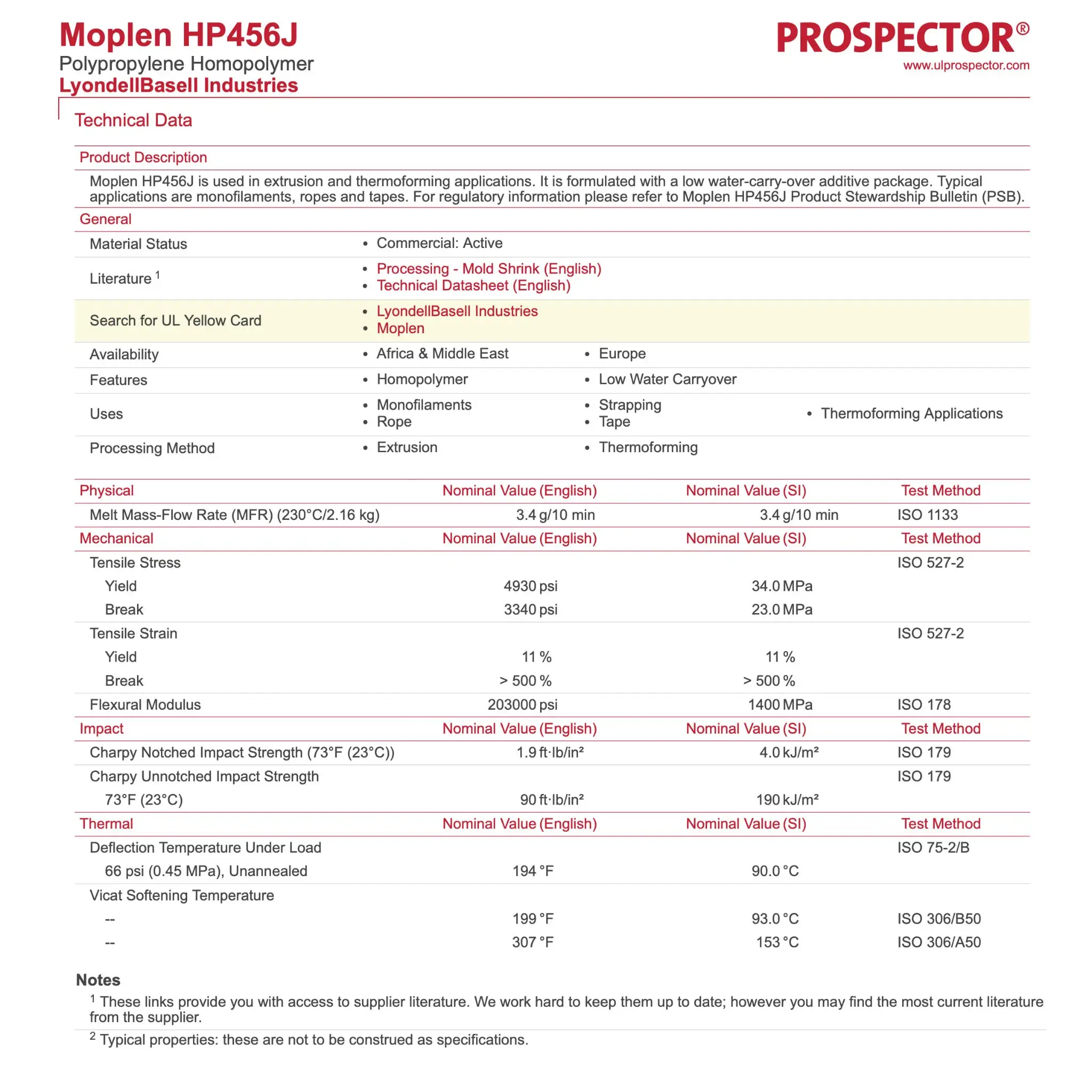

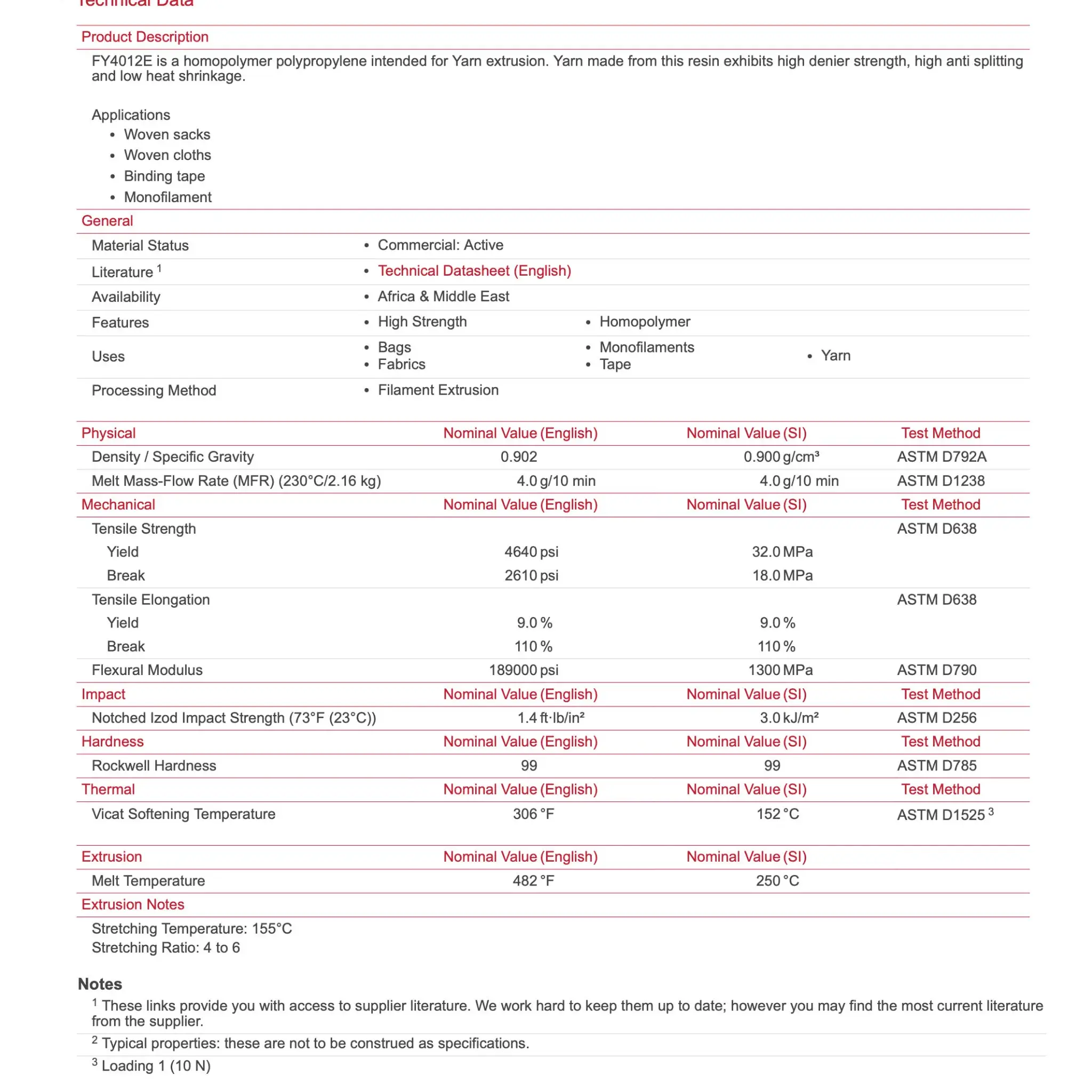

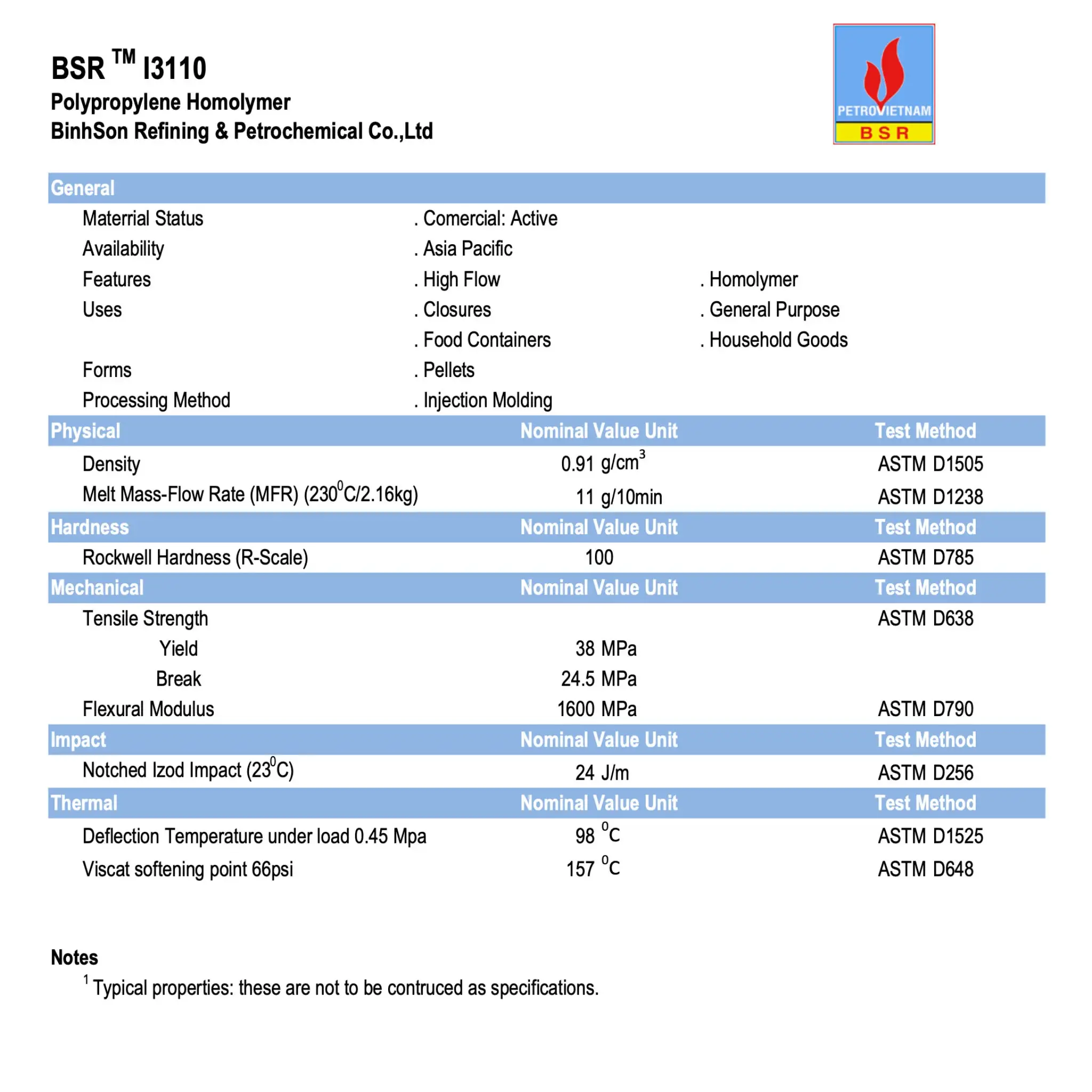

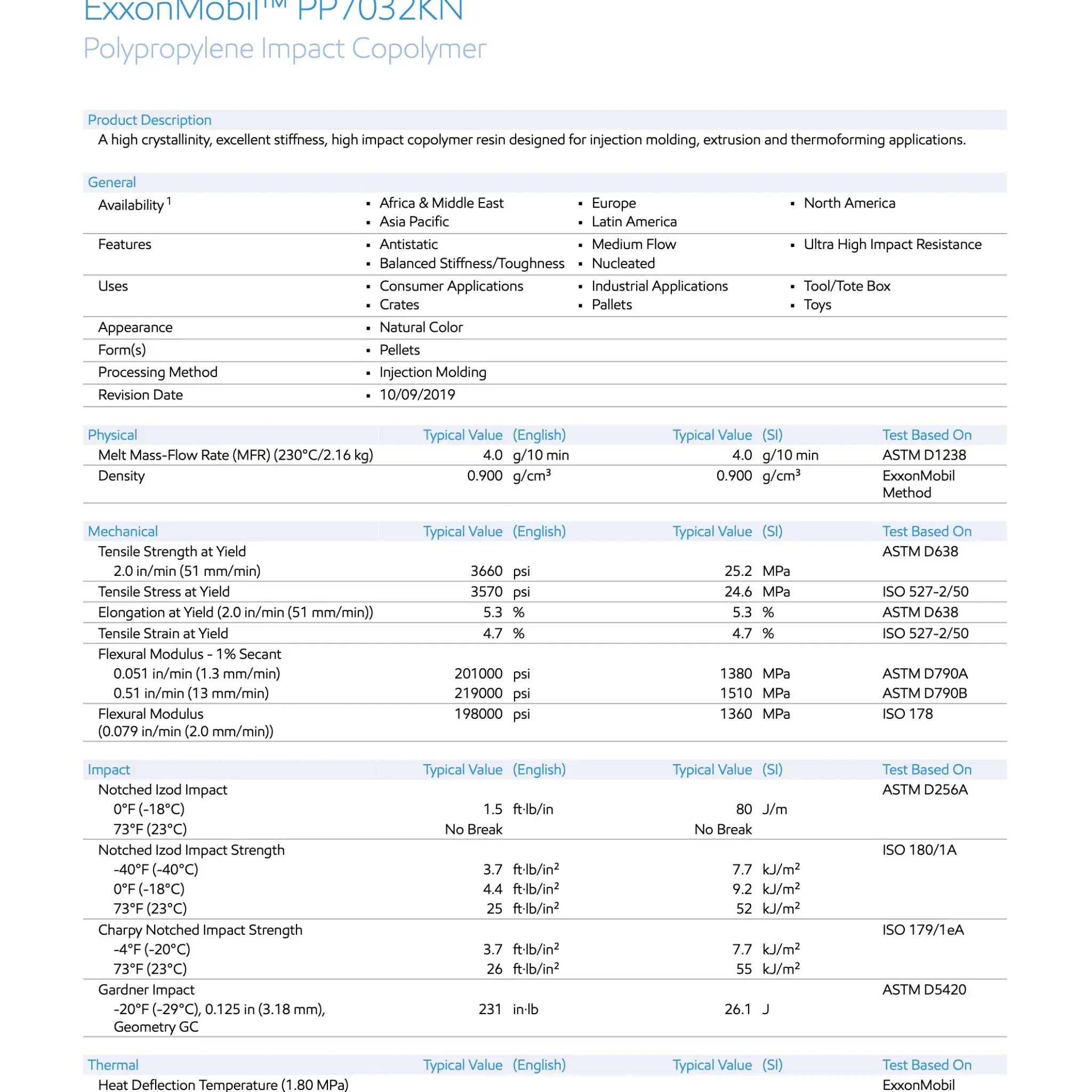

Physical ASTM D1505 ASTM D1238 TPE Hardness ASTM D785

Mechanical ASTM D638 ASTM D790 Impact ASTM D256

Thermal ASTM D648 ASTM D1525 ASTM D2117

Flammability UL 94

Injection Injection Notes

Packing and Holding: 30-60%

Back: 10% of Max Pressure