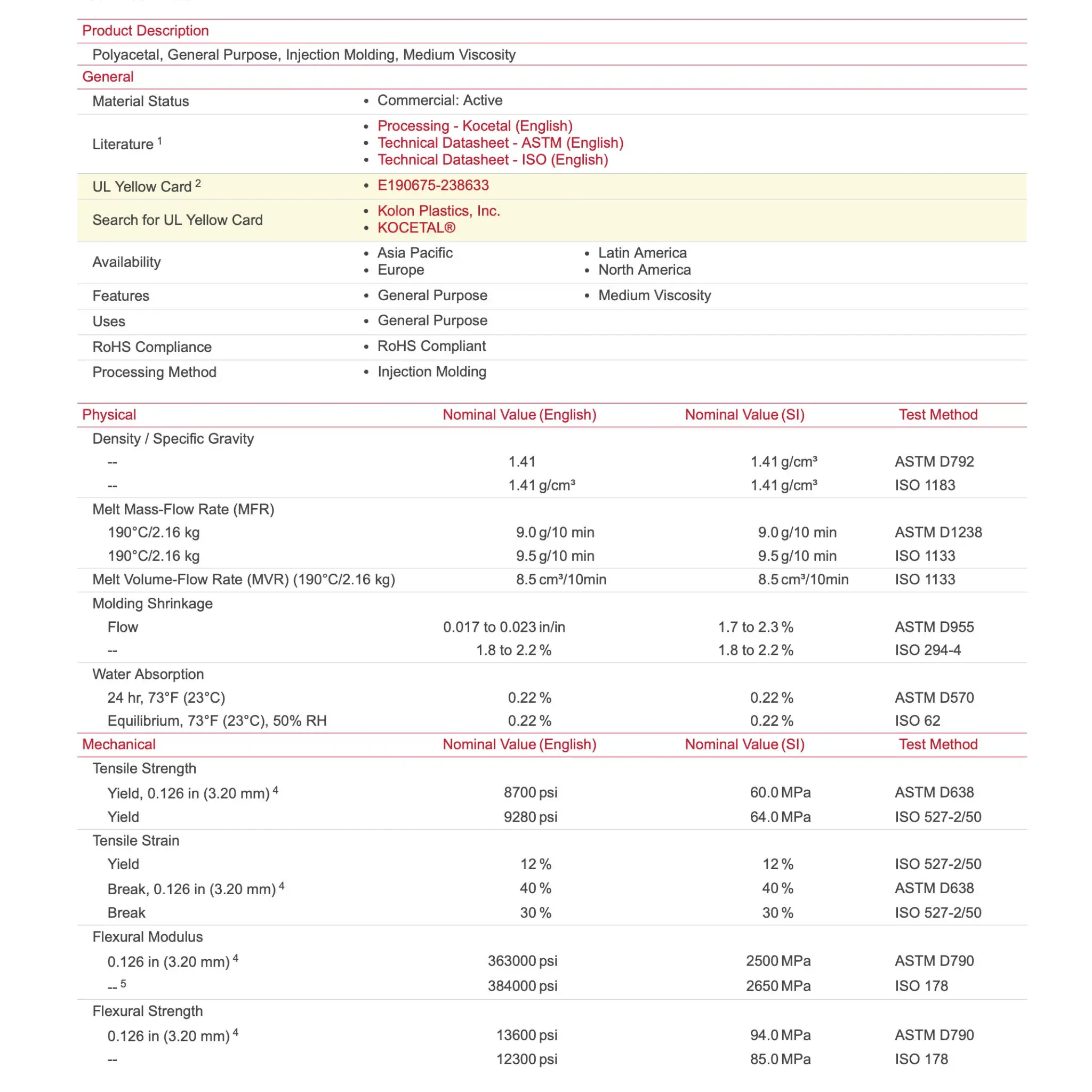

Iupital POM F20-03 là vật liệu Copolyme Acetal (POM). Nó có sẵn ở Châu Á Thái Bình Dương, Châu Âu hoặc Bắc Mỹ để ép phun. Nó có các thuộc tính quan trọng như khả năng chống cháy và độ nhớt trung bình.

General

Physical ISO 1183 ISO 1133 ISO 1133 Internal Method Internal Method

Mechanical ISO 527-1/1 ISO 527-2/50 ISO 527-2/50 ISO 178 ISO 178 Impact ISO 179 ISO 179

Thermal ISO 75-2/B ISO 75-2/A ISO 11357-3 ISO 11359-2

Electrical IEC 60093 IEC 60093 IEC 60243-1 IEC 60250 IEC 60250 IEC 60112 Flammability UL 94

Injection