5401GT Enhanced Polyethylene Resin is a copolymer produced via INSITE™ Technology from Dow. It offers extremely high impact resistance, combined with excellent tear, tensile and optical properties for high strength blown film applications. ELITE 5401GT Enhanced Polyethylene Resin offers a unique combination of low seal initiation temperature and high modulus and low blocking tendency for automatic packaging applications. ELITE 5401GT Enhanced Polyethylene Resin contains slip and antiblock additives.

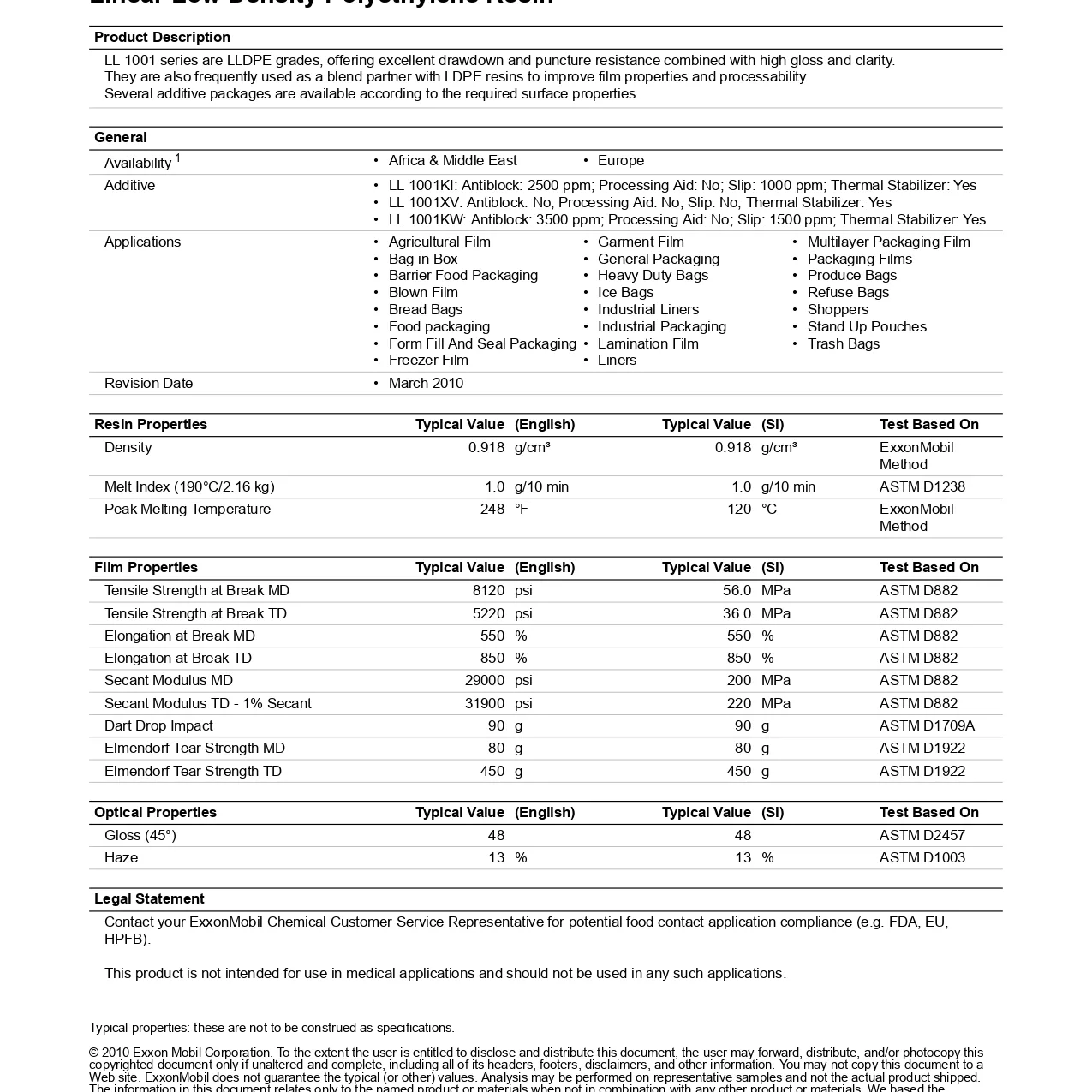

General Material Status Availability Additive Agency Ratings Forms Processing Method

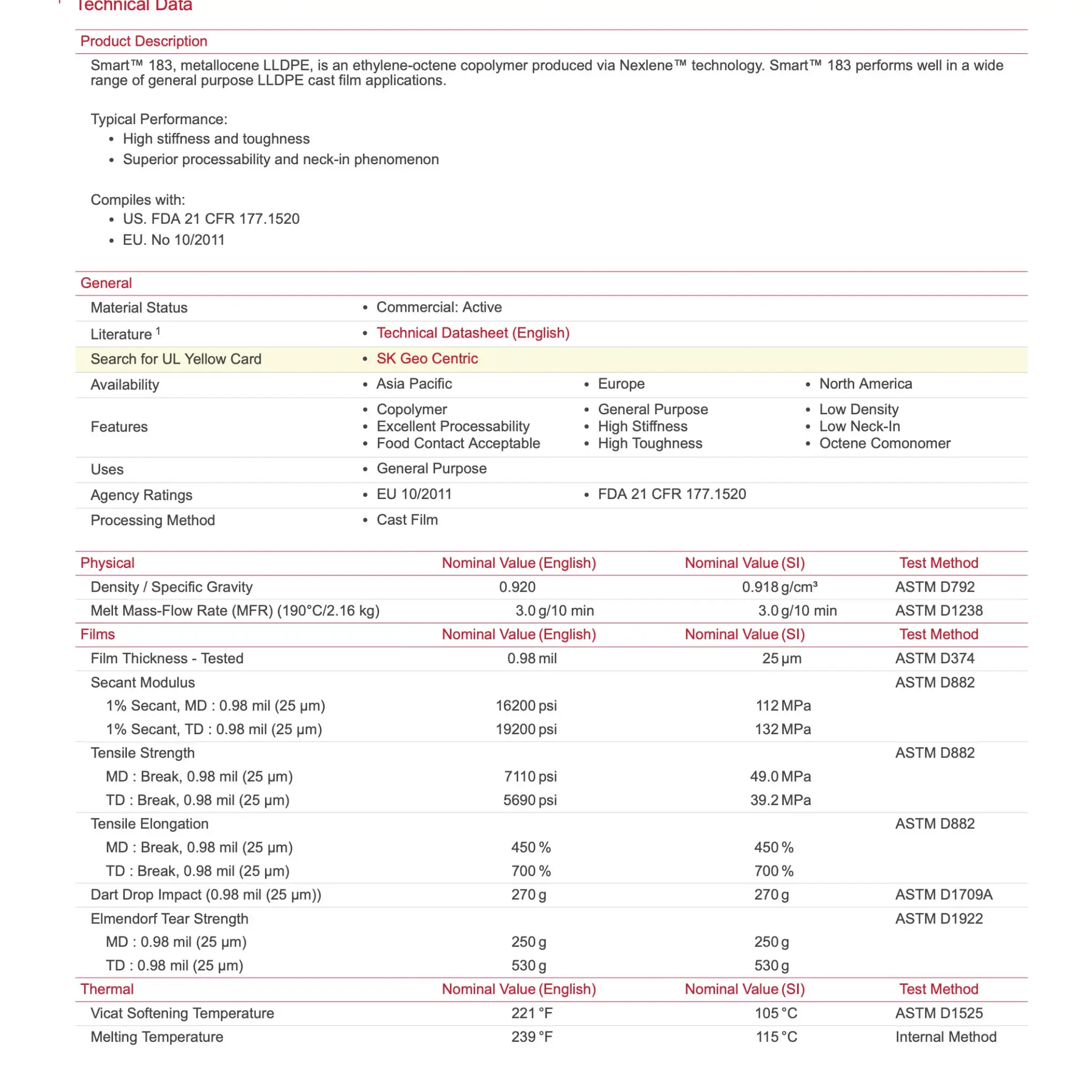

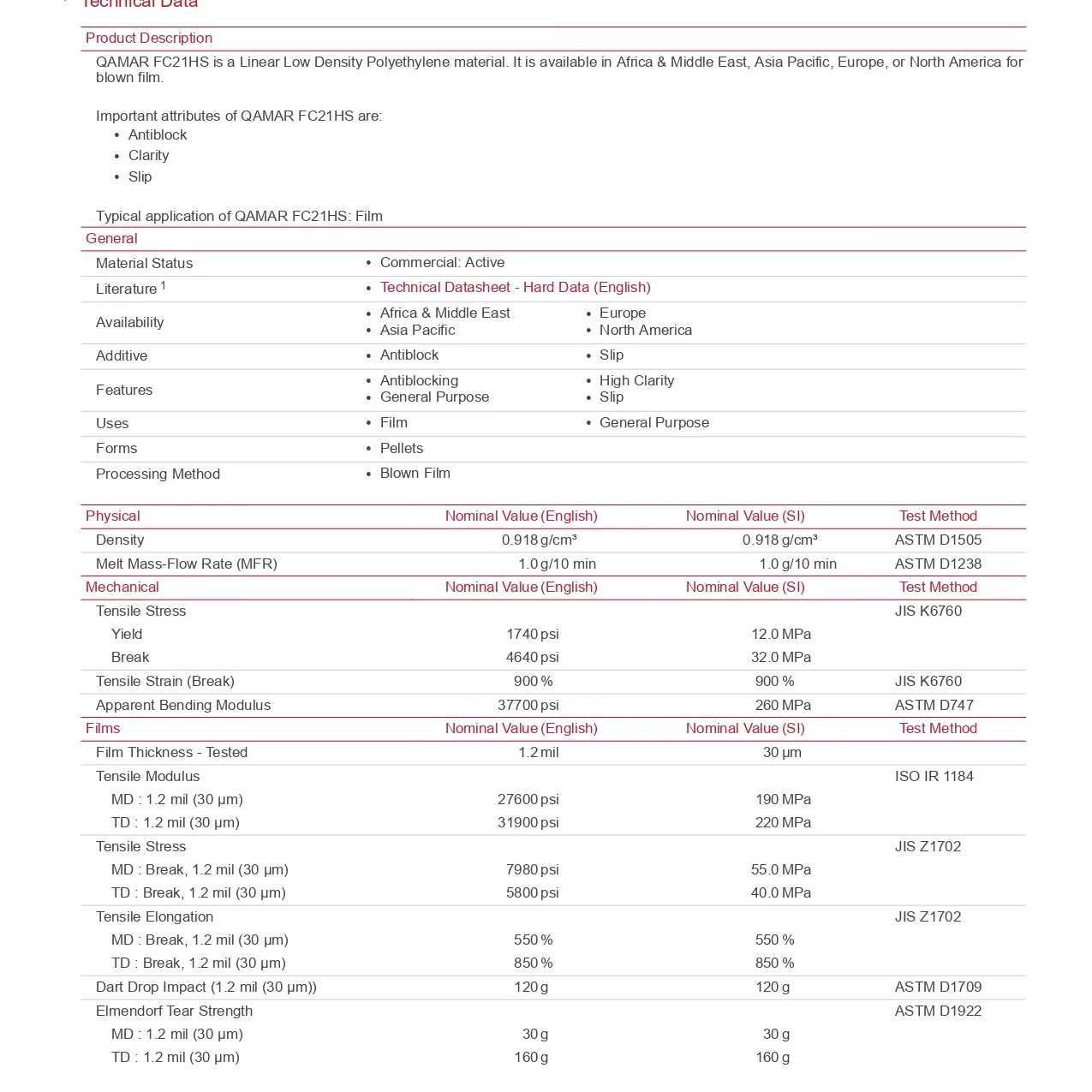

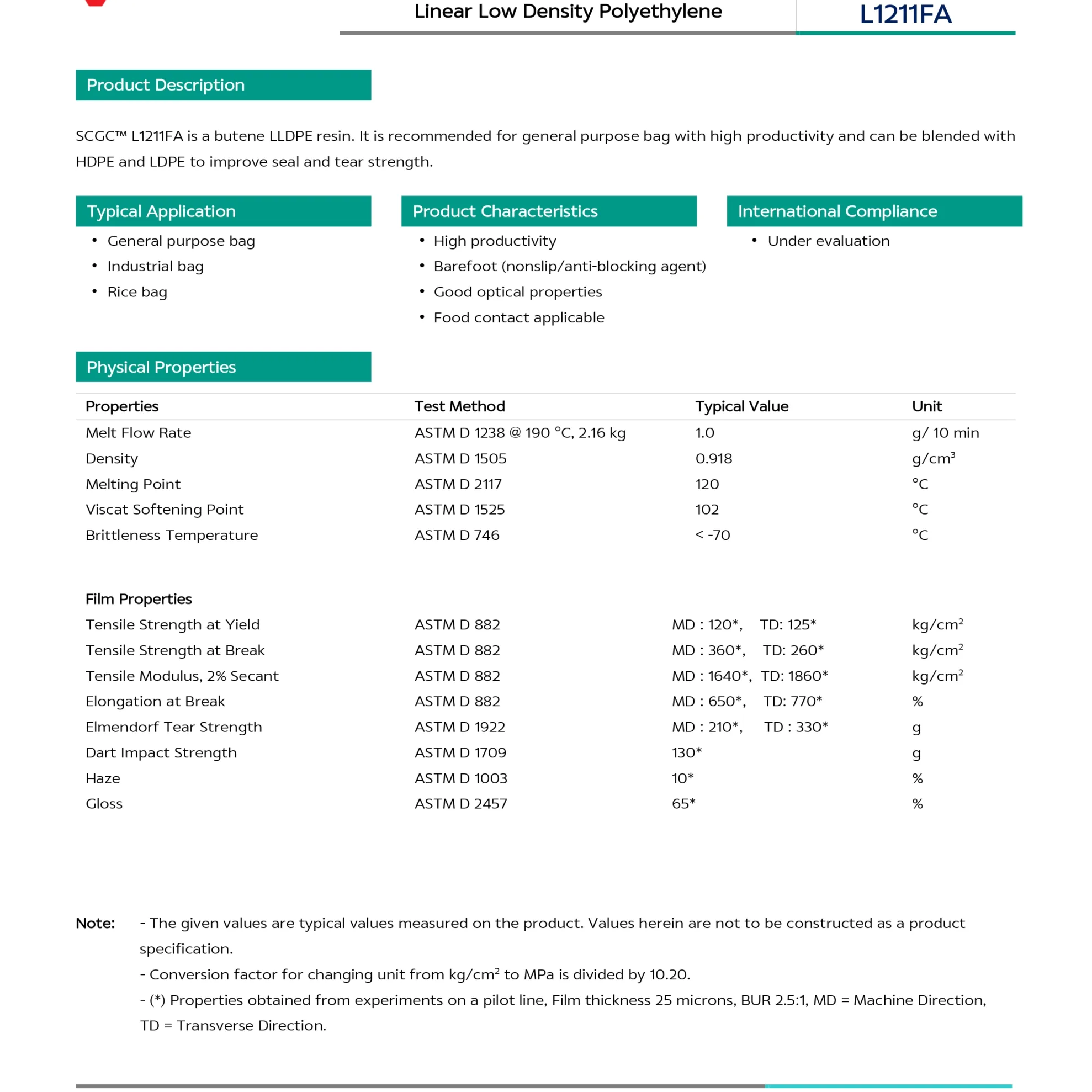

Physical Density / Specific Gravity ASTM D792 Melt Mass-Flow Rate (MFR) (190°C/2.16 kg) ISO 1133

Films Film Thickness - Tested Film Puncture Energy (2.0 mil) ASTM D5748 Film Puncture Force (2.0 mil) ASTM D5748 Tensile Modulus ISO 527-3 2% Secant, MD : 2.0 mil ISO 527-3 2% Secant, TD : 2.0 mil ISO 527-3 Tensile Stress ISO 527-3 MD : Yield, 2.0 mil ISO 527-3 TD : Yield, 2.0 mil ISO 527-3 MD : Break, 2.0 mil ISO 527-3 TD : Break, 2.0 mil ISO 527-3 Tensile Elongation ISO 527-3 MD : Break, 2.0 mil ISO 527-3 TD : Break, 2.0 mil ISO 527-3 Dart Drop Impact (2.0 mil) ISO 7765-1/B Elmendorf Tear Strength ASTM D1922 MD : 2.0 mil ASTM D1922 TD : 2.0 mil ASTM D1922 Seal Initiation Temperature (2.0 mil) Internal Method

Thermal Vicat Softening Temperature ASTM D1525 Melting Temperature DSC

Optical Gloss (45°, 2.01 mil) ASTM D2457 Haze (2.01 mil) ISO 14782

Extrusion Melt Temperature Extrusion Notes