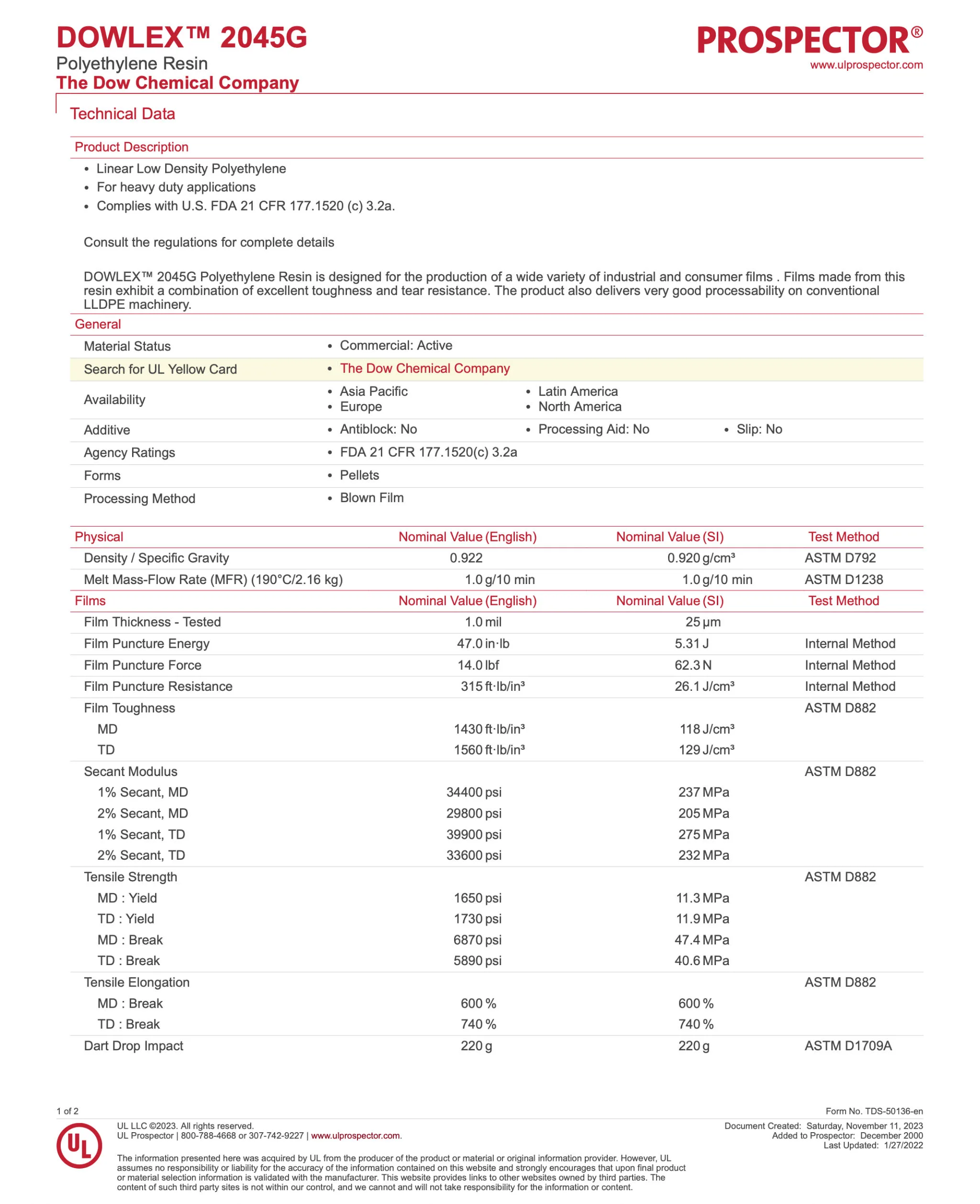

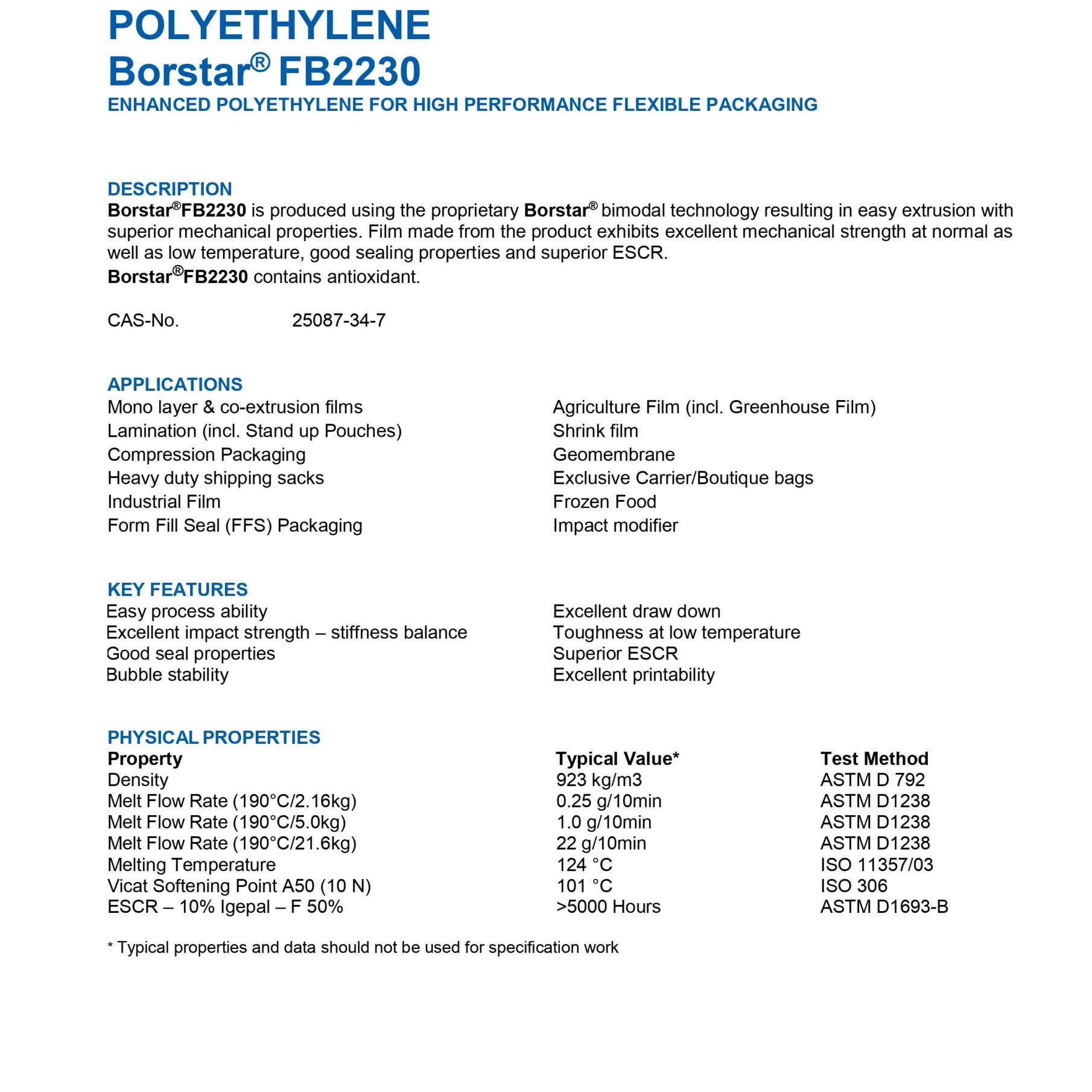

Dowlex LLDPE 2045G is designed for the production of a wide variety of industrial and consumer films. Films made from this resin exhibit a combination of excellent toughness and tear resistance. The product also delivers very good processability on conventional LLDPE machinery.

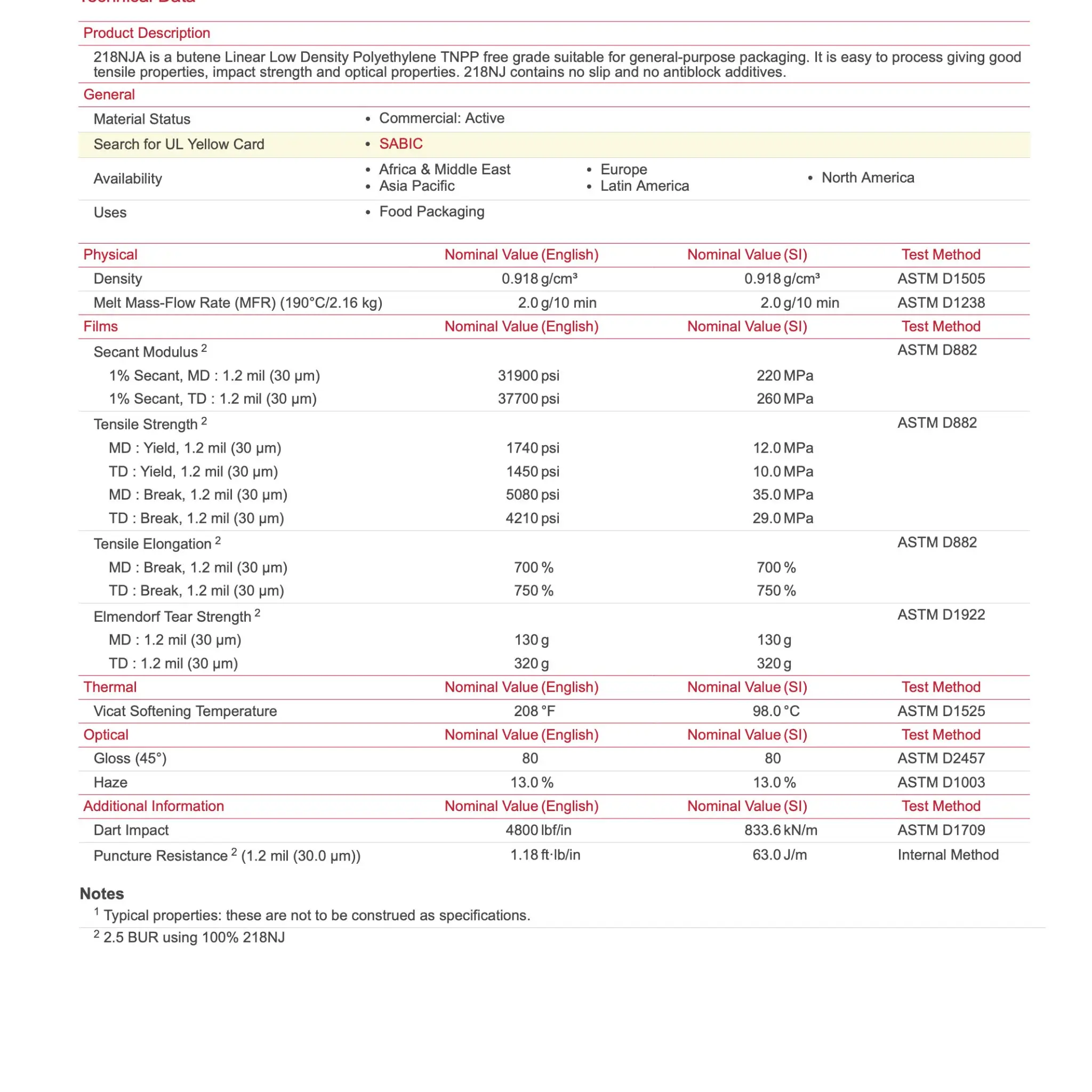

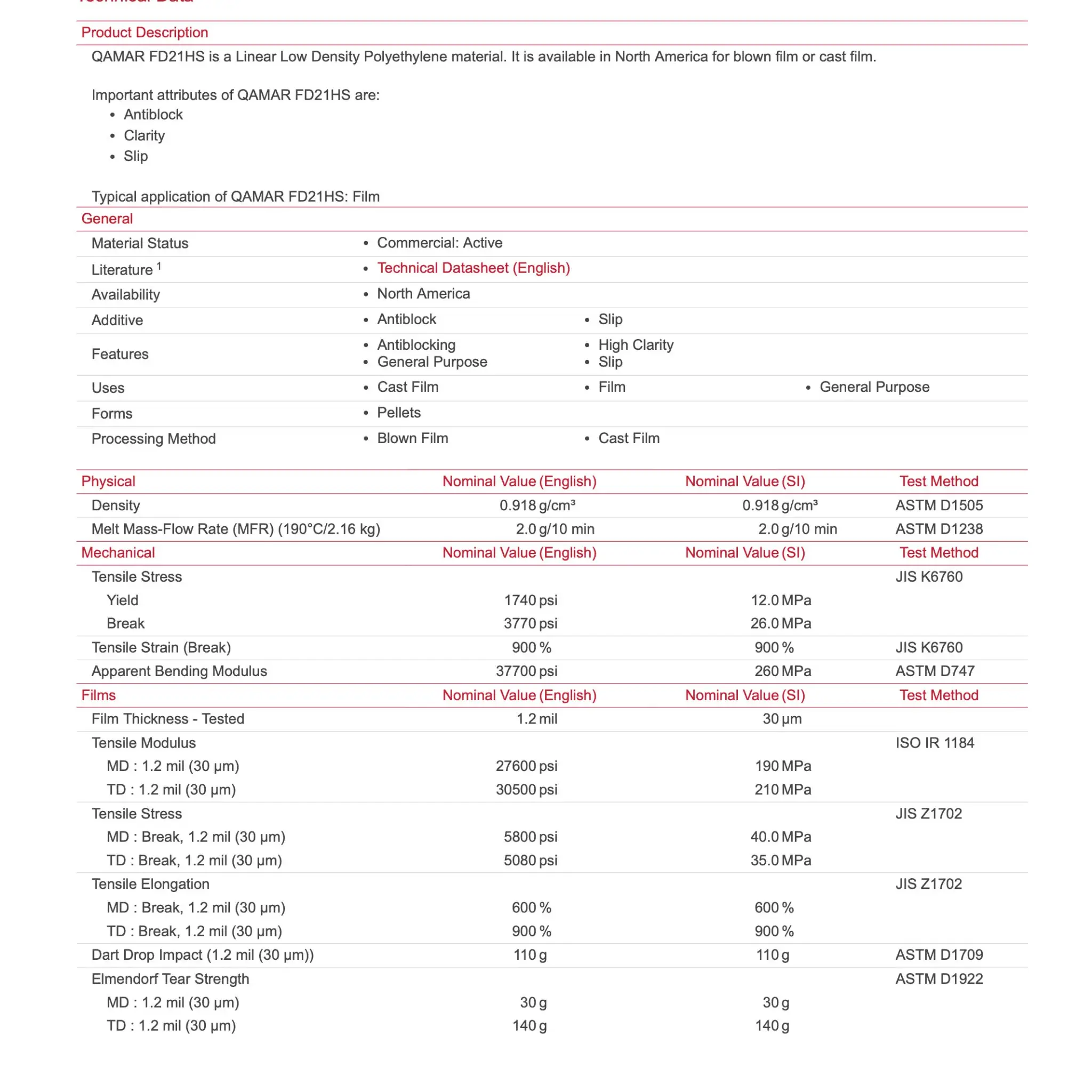

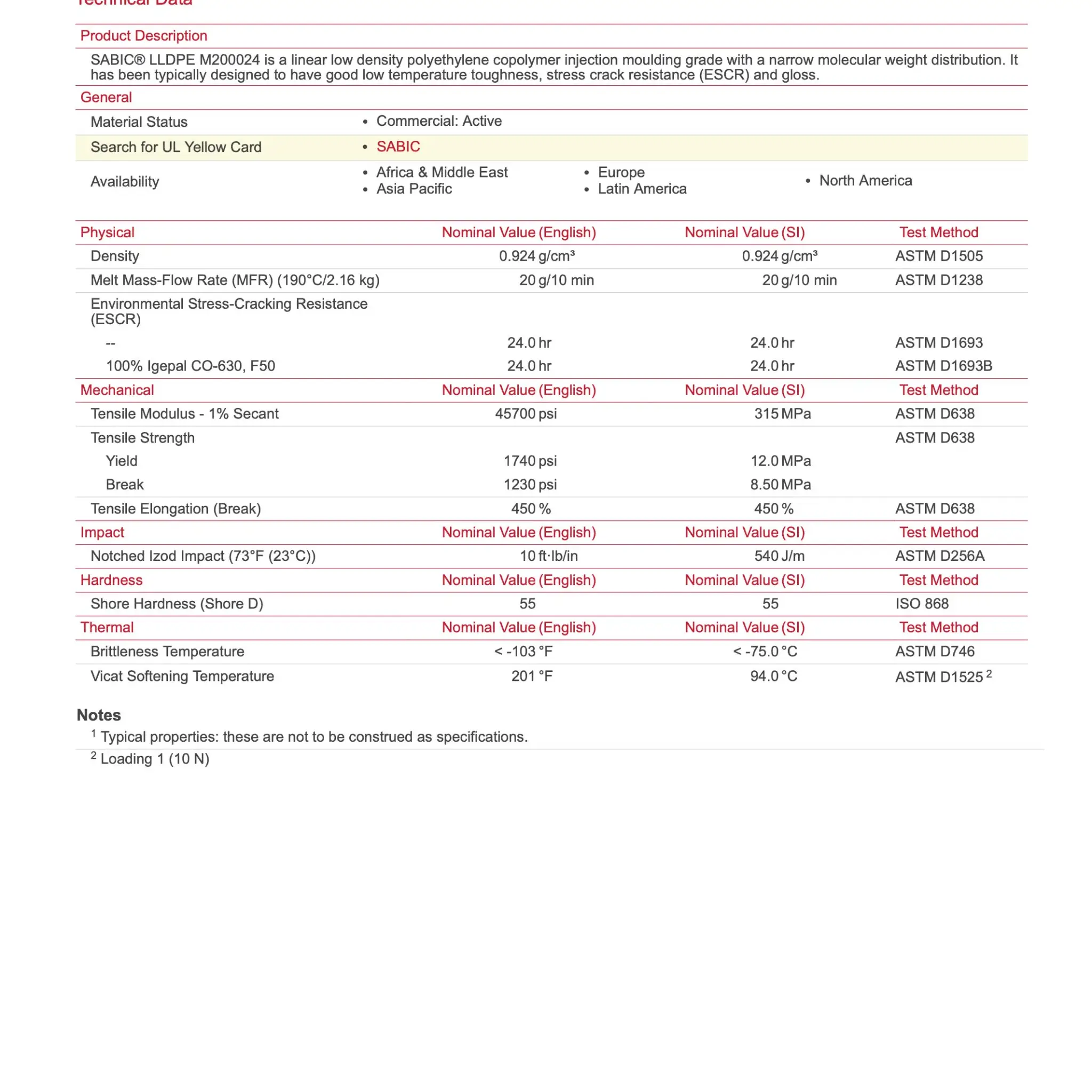

General

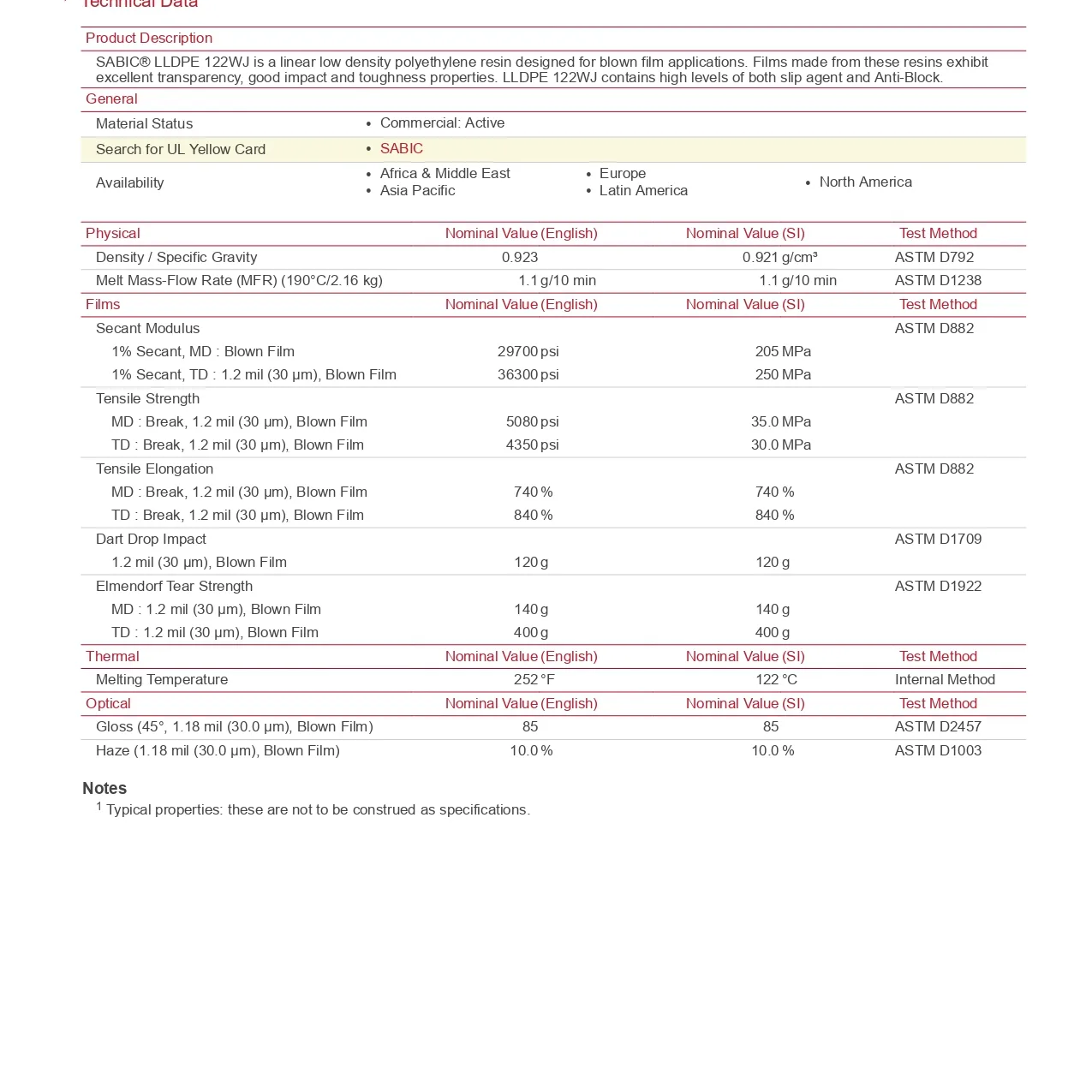

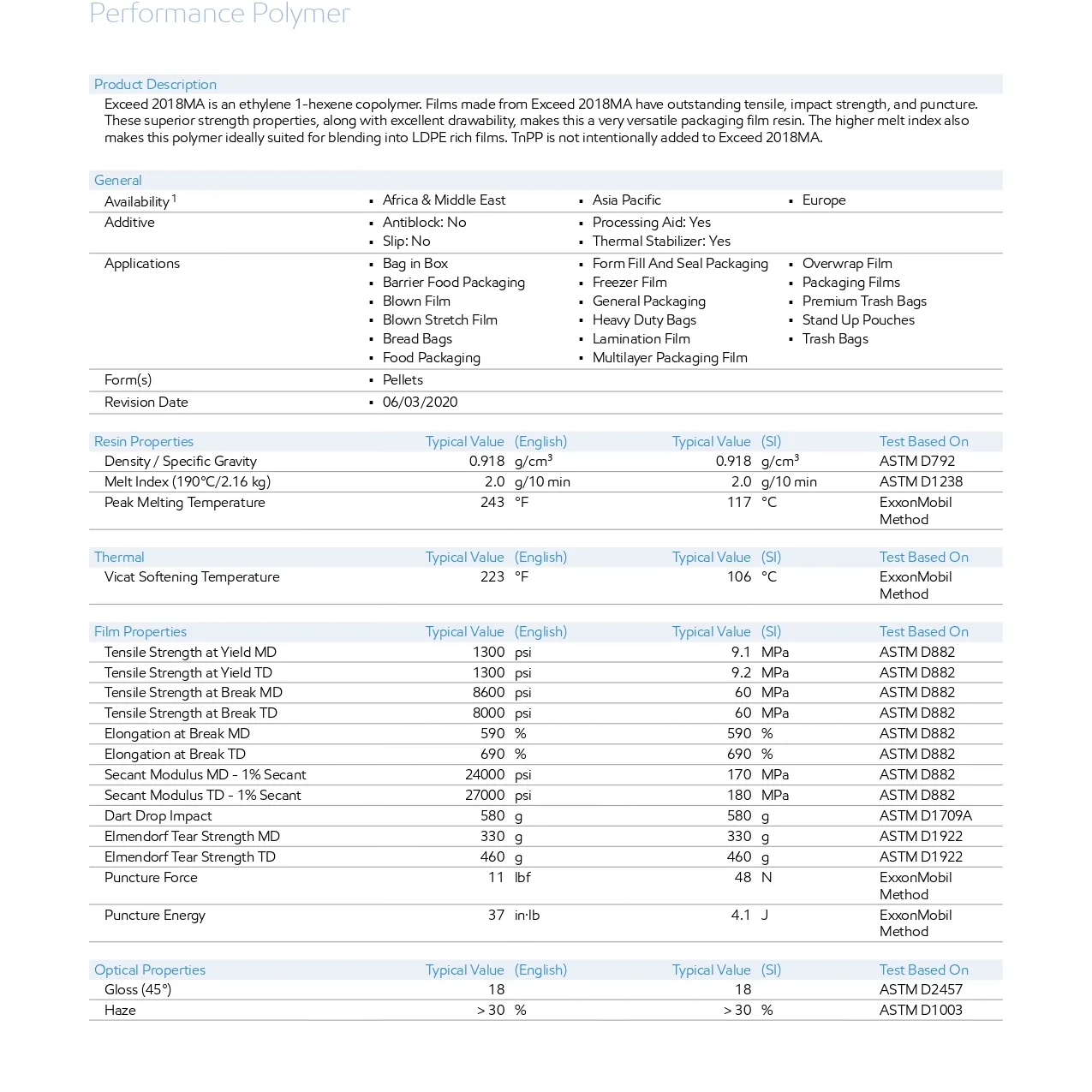

Physical ASTM D792 ASTM D1238

Films Internal Method Internal Method Internal Method ASTM D882 ASTM D882 ASTM D882 ASTM D882 ASTM D1709A ASTM D1922

Thermal ASTM D1525 Internal Method

Optical ASTM D2457 ASTM D1003

Extrusion Notes