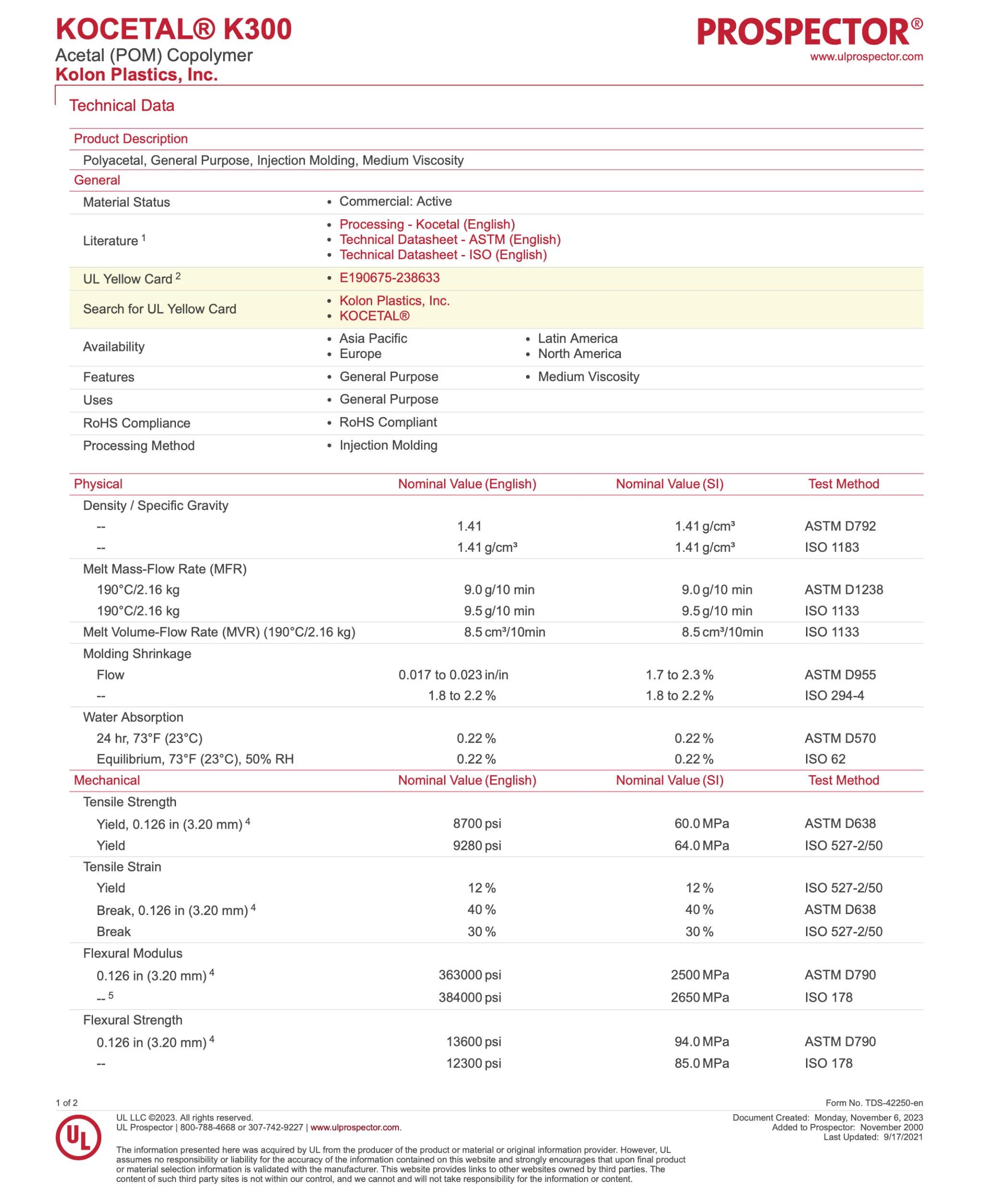

KOCETAL POM K300 by Kolon Plastics (Kolon Industries) is a general-purpose, medium-viscosity polyacetal polyoxymethylene copolymer grade that imparts good processability, high toughness, and high crystallinity and does not deflect over the heat deflection temperature. It possesses good mechanical strength, high stiffness, and good dimensional stability. It exhibits heat-, friction-, chemical-, oil, and wear resistance. It is suitable for processing by injection molding.

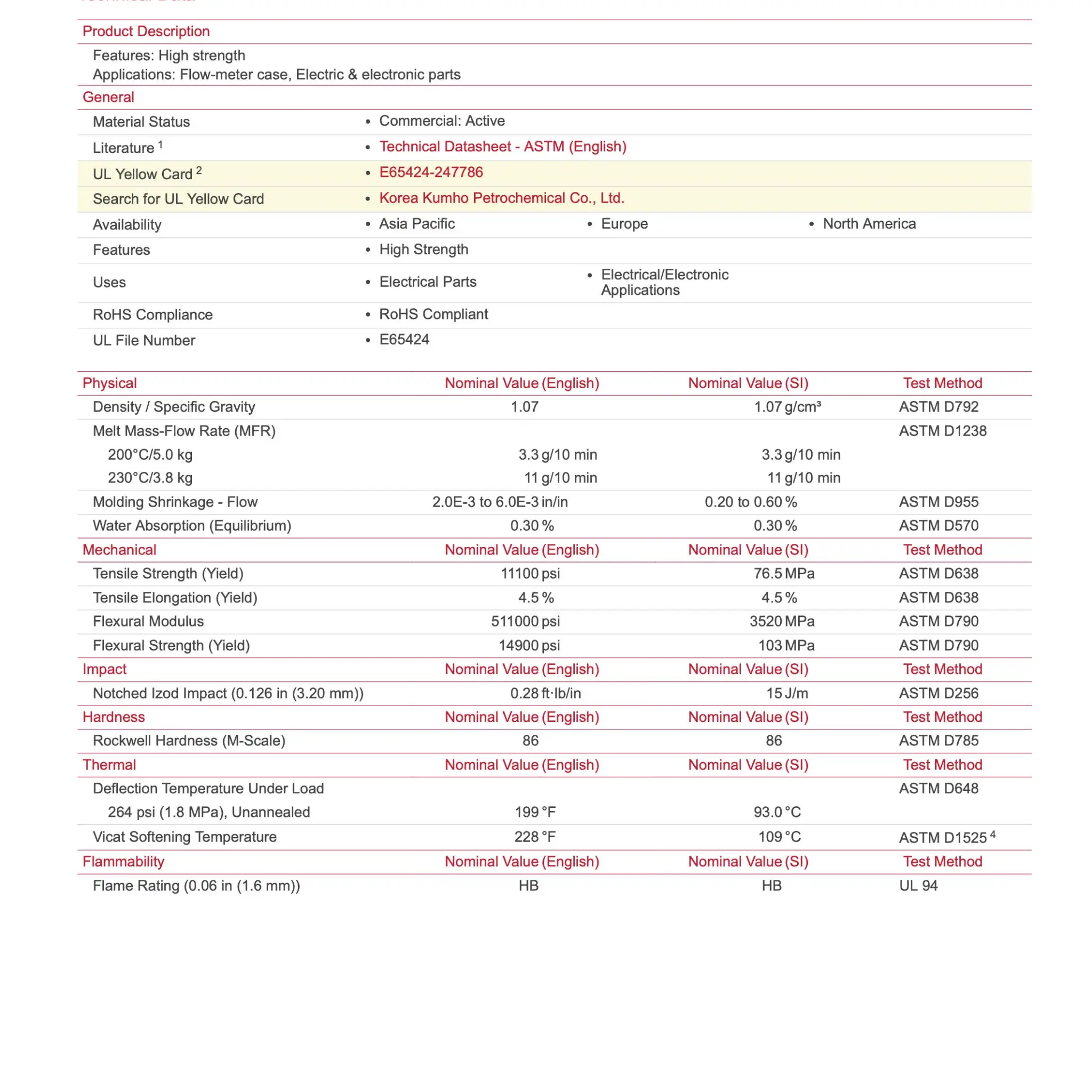

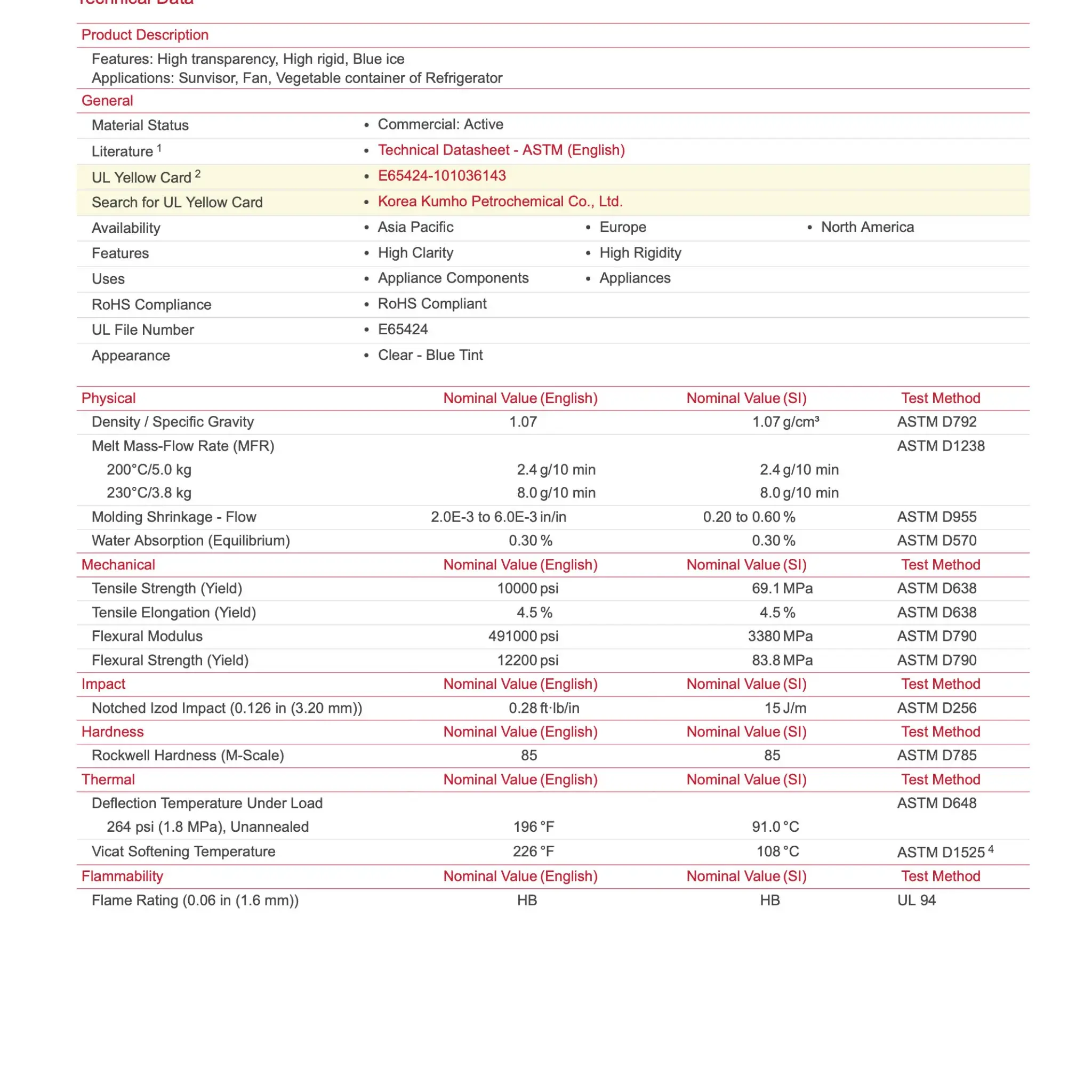

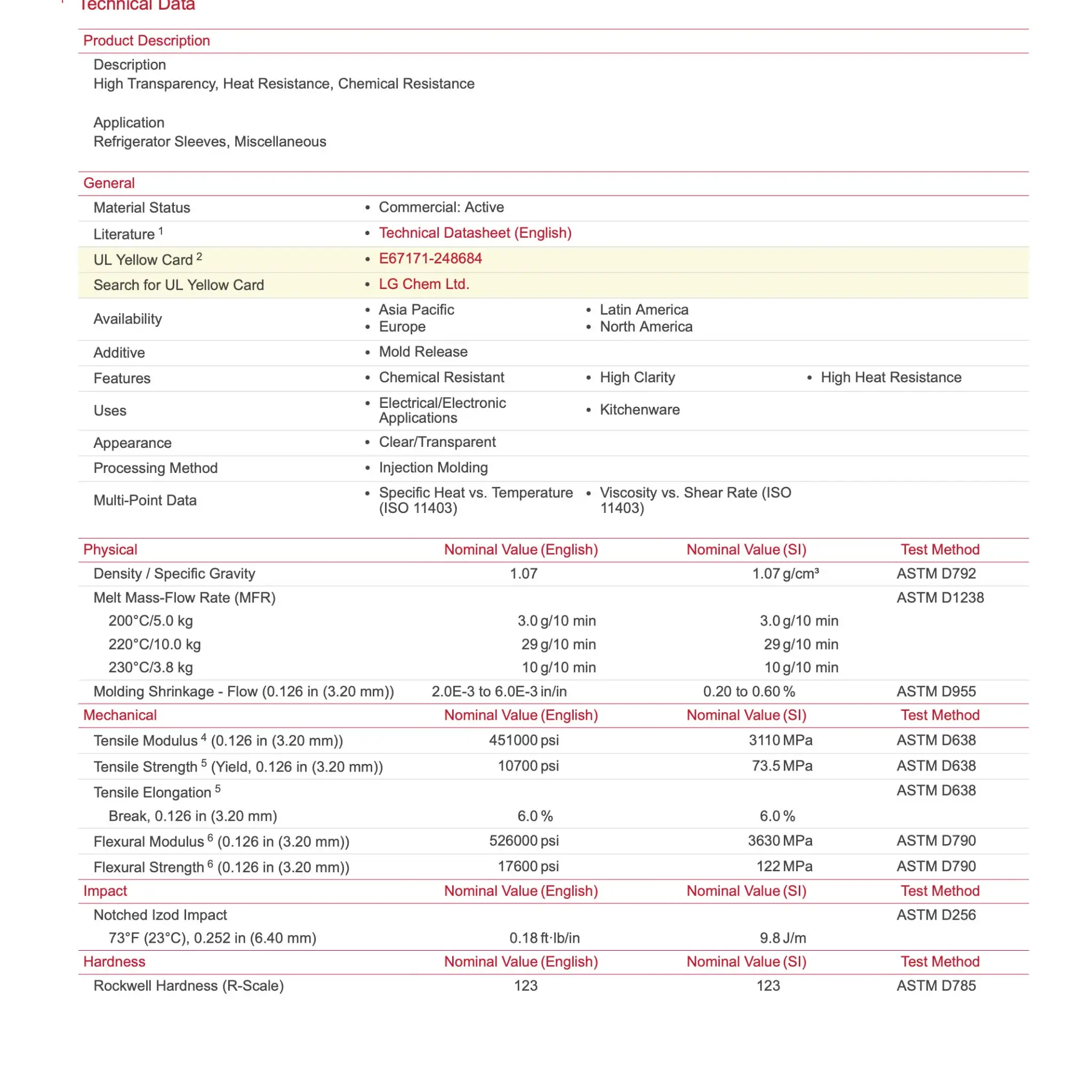

General

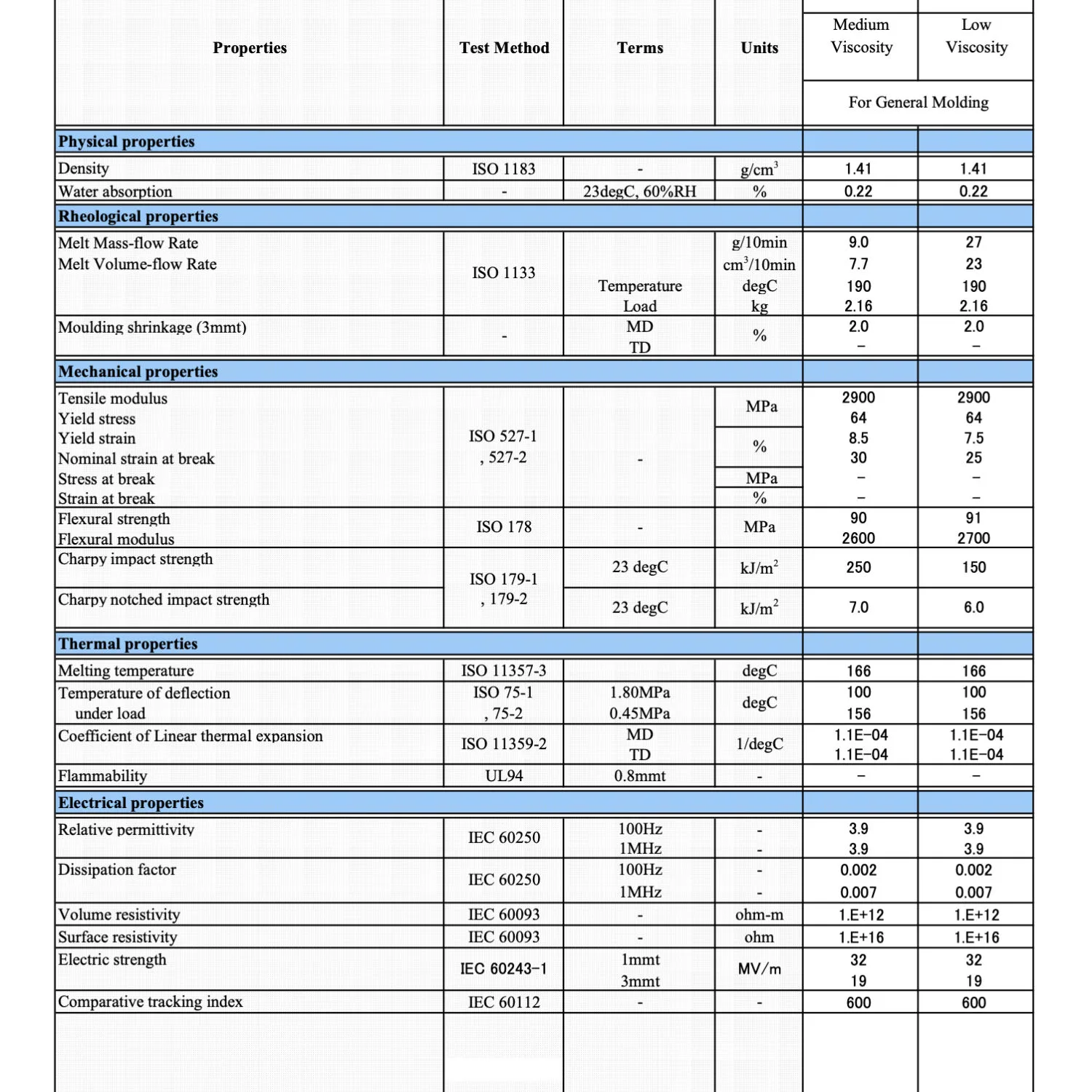

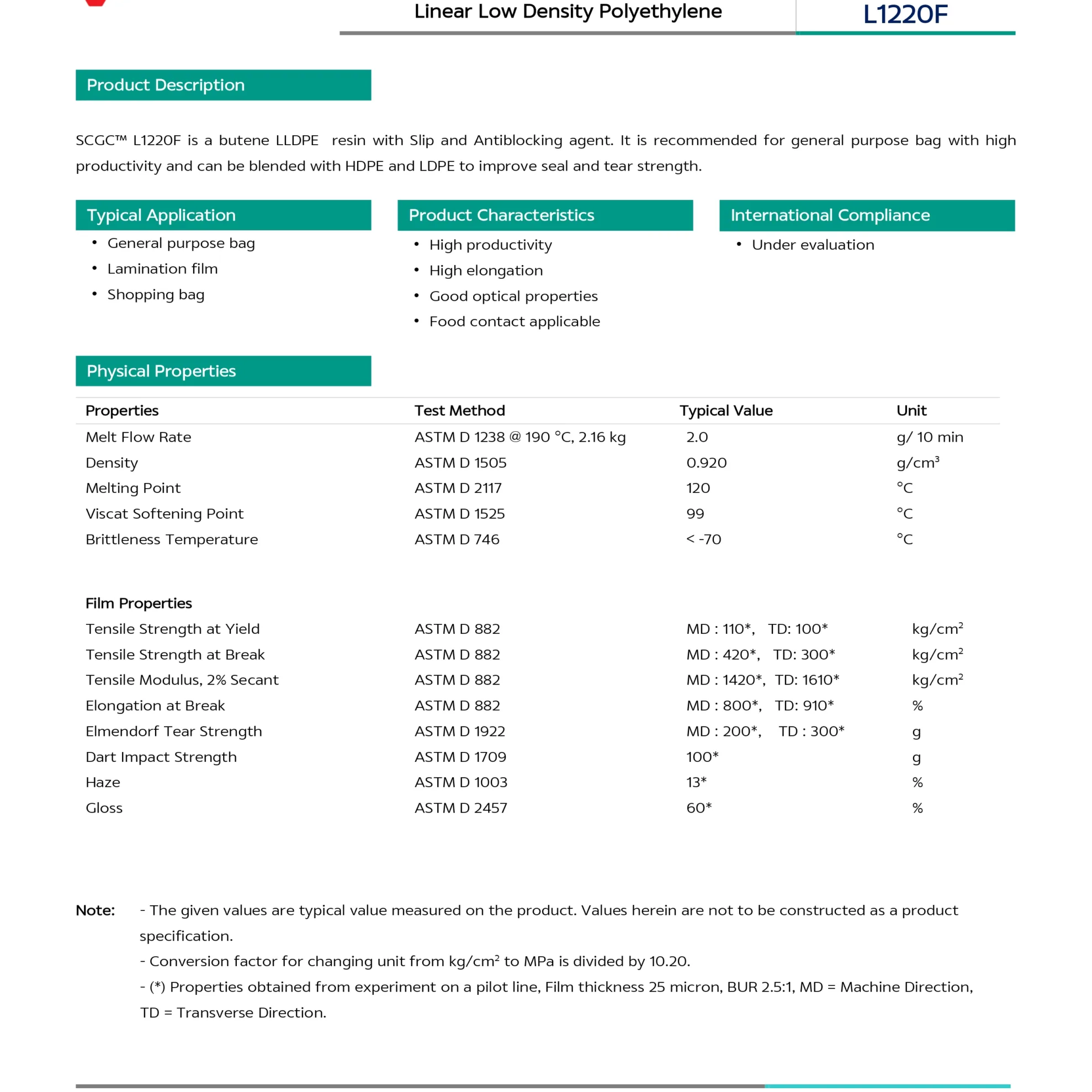

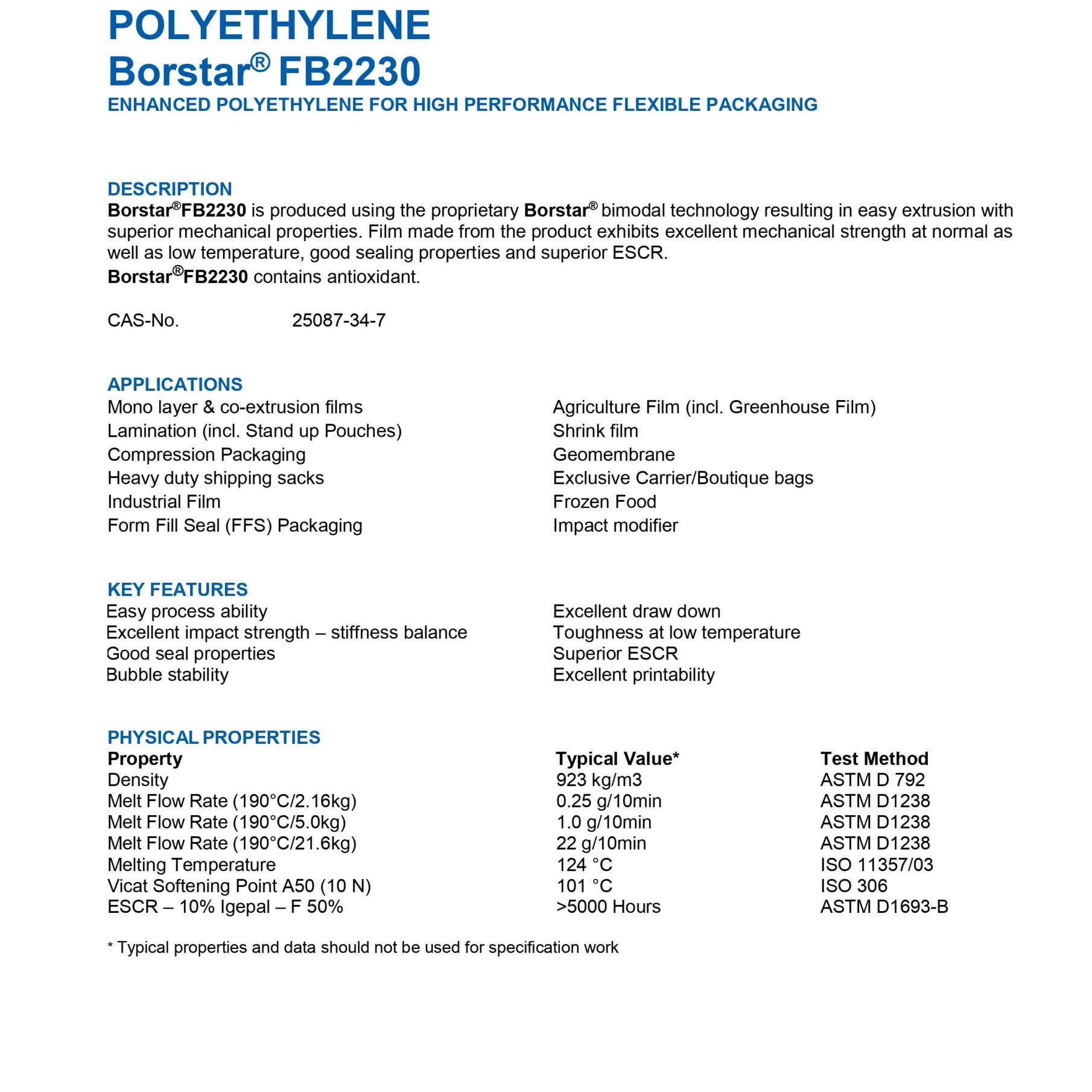

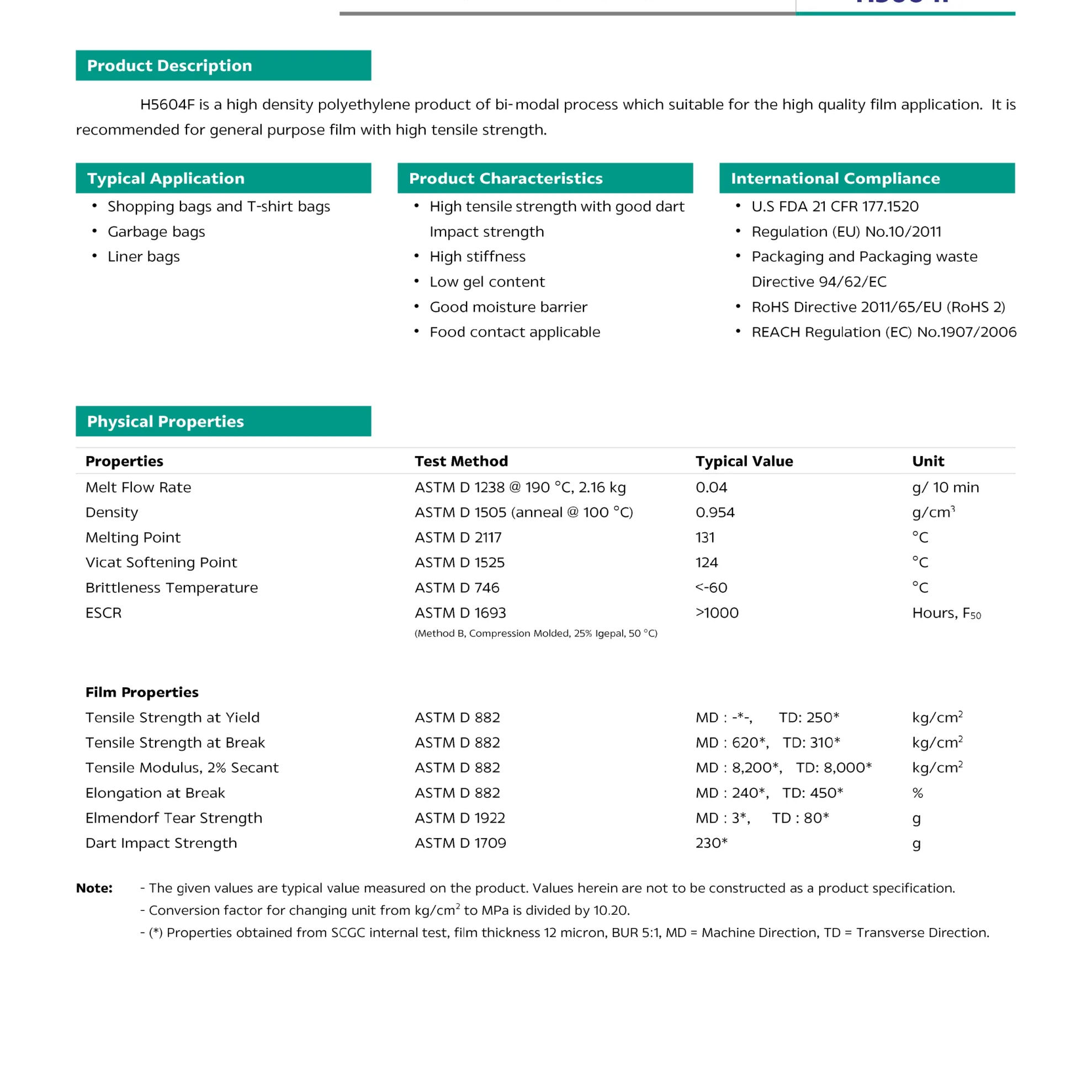

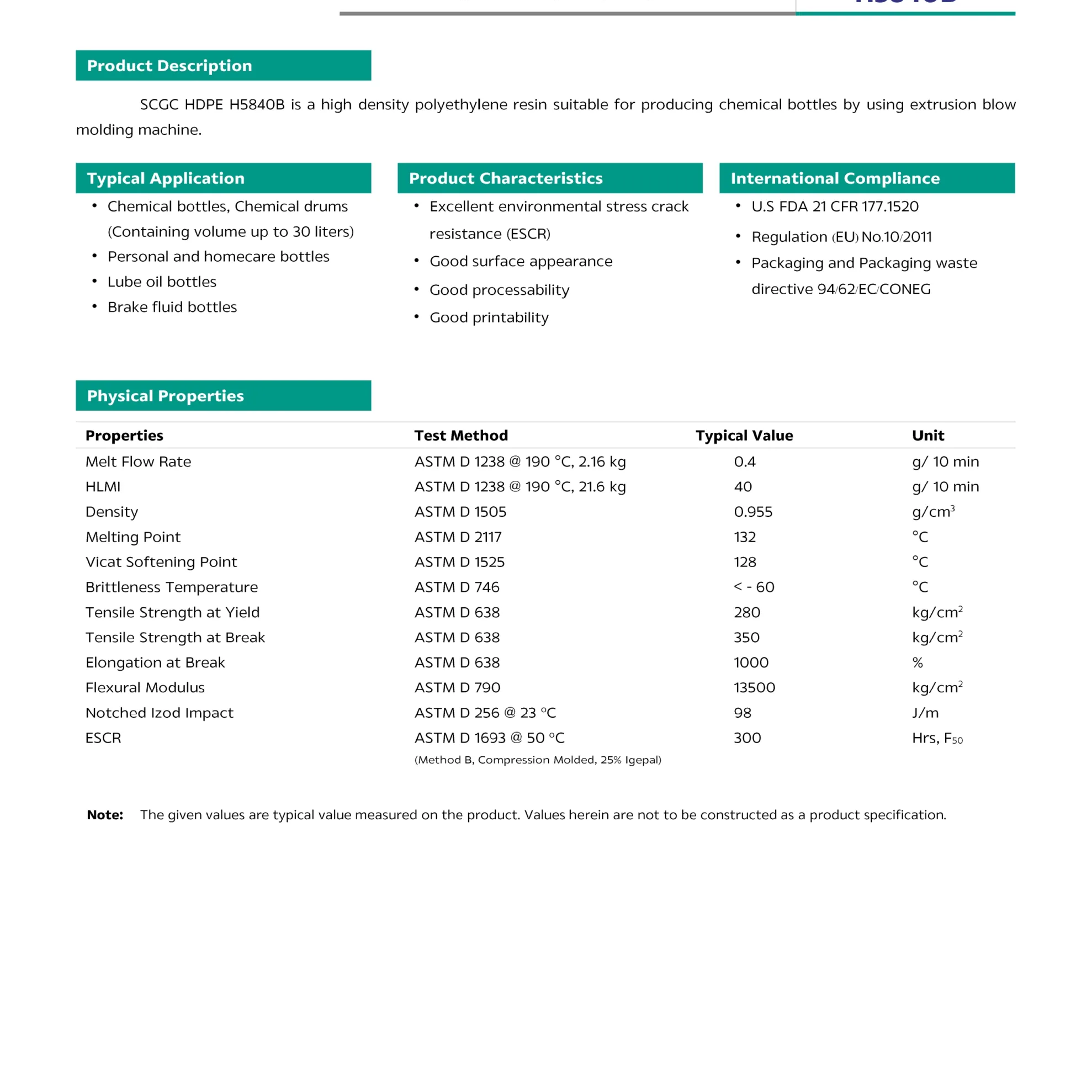

Physical ASTM D792 ISO 1183 ASTM D1238 ISO 1133 ISO 1133 ASTM D955 ISO 294-4 ASTM D570 ISO 62 Hardness ASTM D785, ISO 2039-2

Mechanical ASTM D638 ISO 527-2/50 ISO 527-2/50 ASTM D638 ISO 527-2/50 ASTM D790 ISO 178 ASTM D790 ISO 178 Impact ISO 179/1eA ASTM D256

Thermal ASTM D648 ISO 75-2/A ISO 11357-3, ASTM D1525 ASTM D696

Electrical IEC 60093 Flammability UL 94

Injection