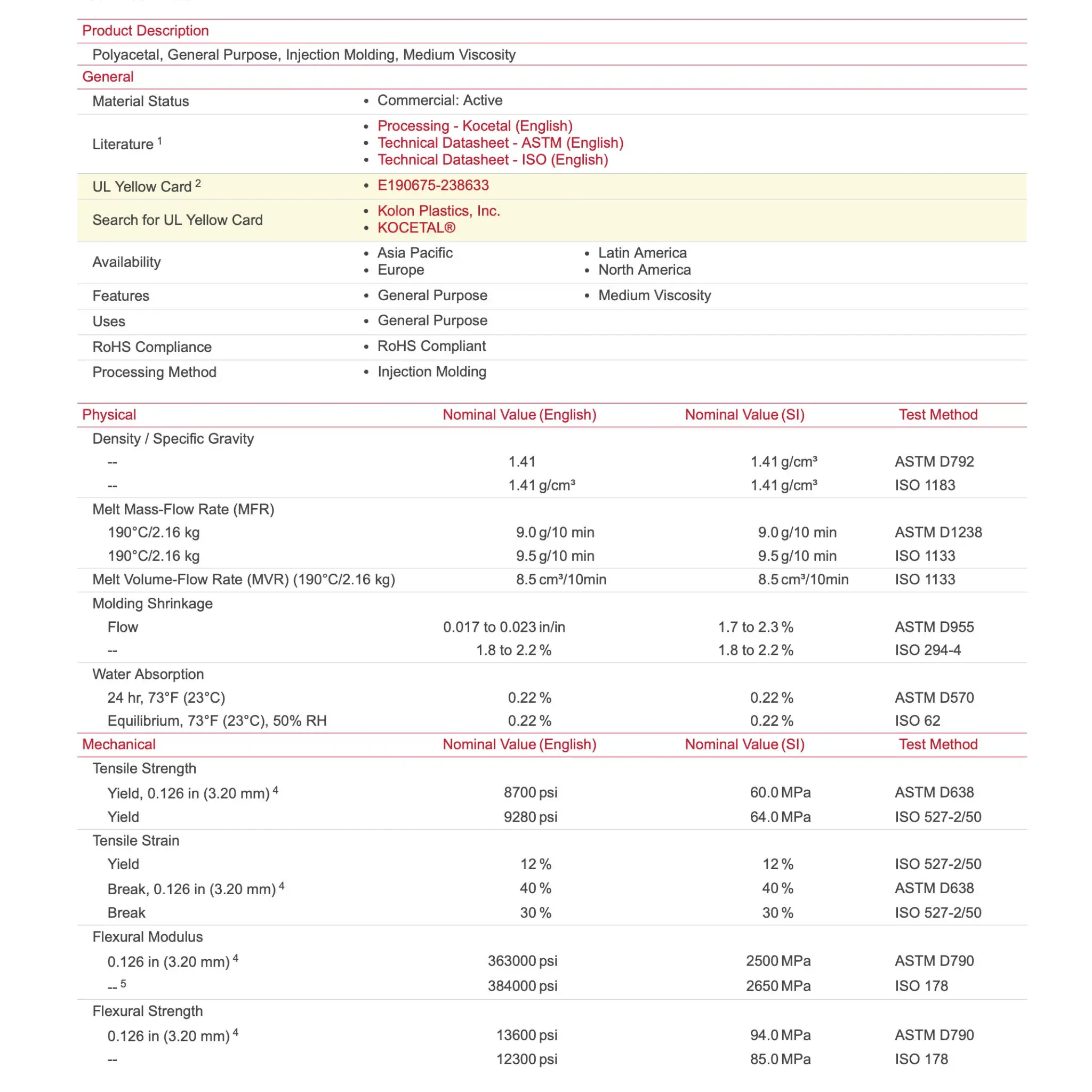

Iupital POM F20-03 is an Acetal (POM) Copolymer material. It is available in Asia Pacific, Europe, or North America for injection molding. It has important attributes such as flame-rated and medium viscosity.

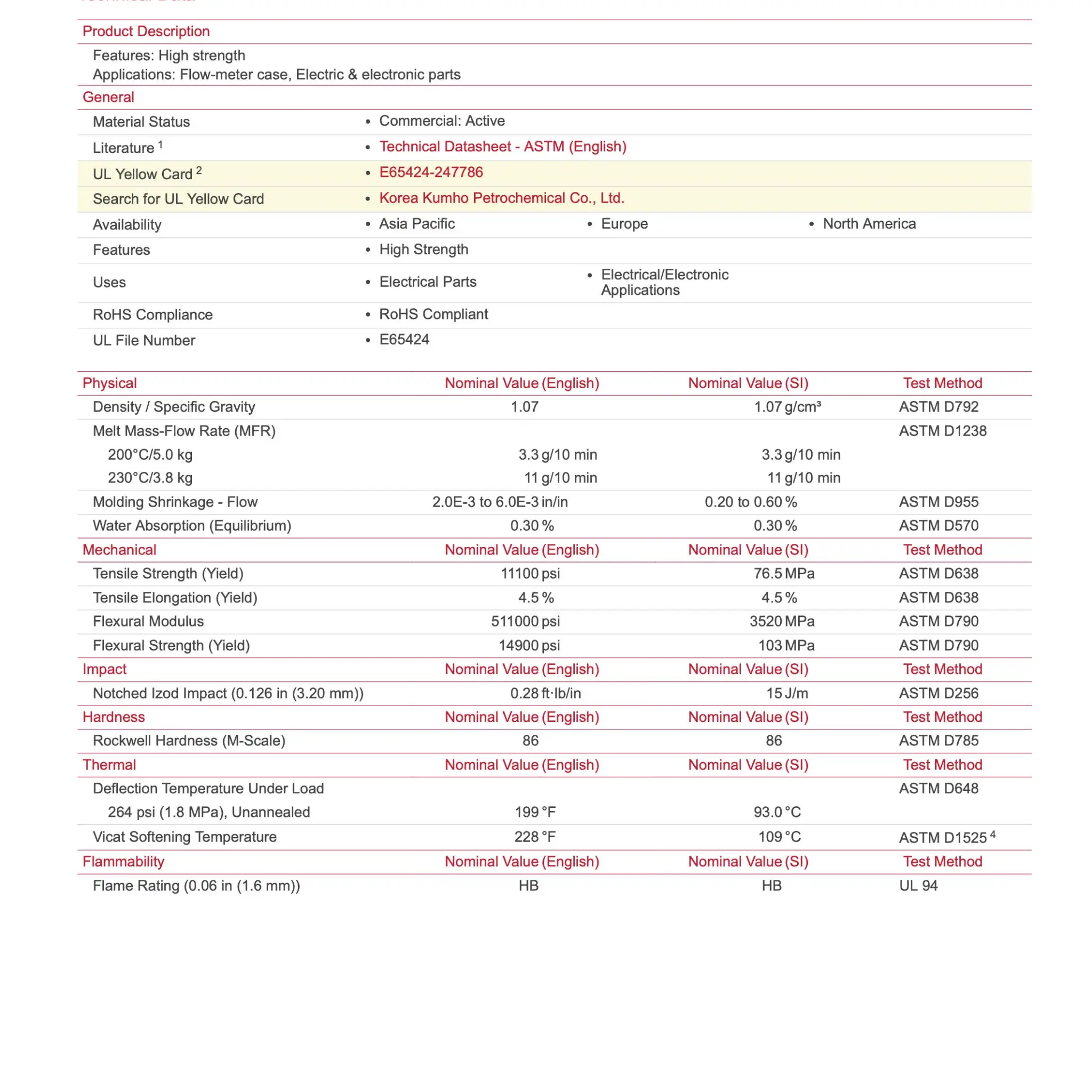

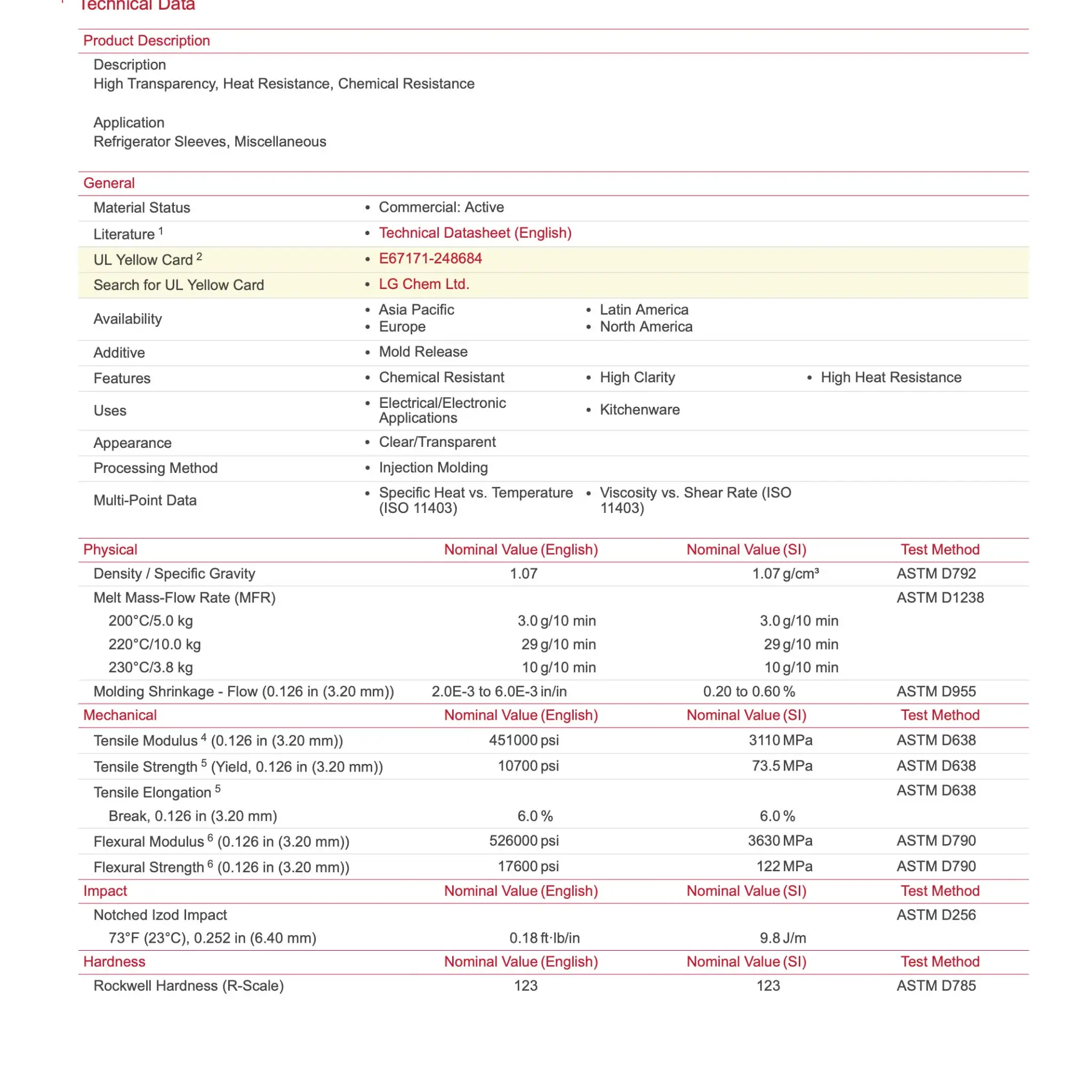

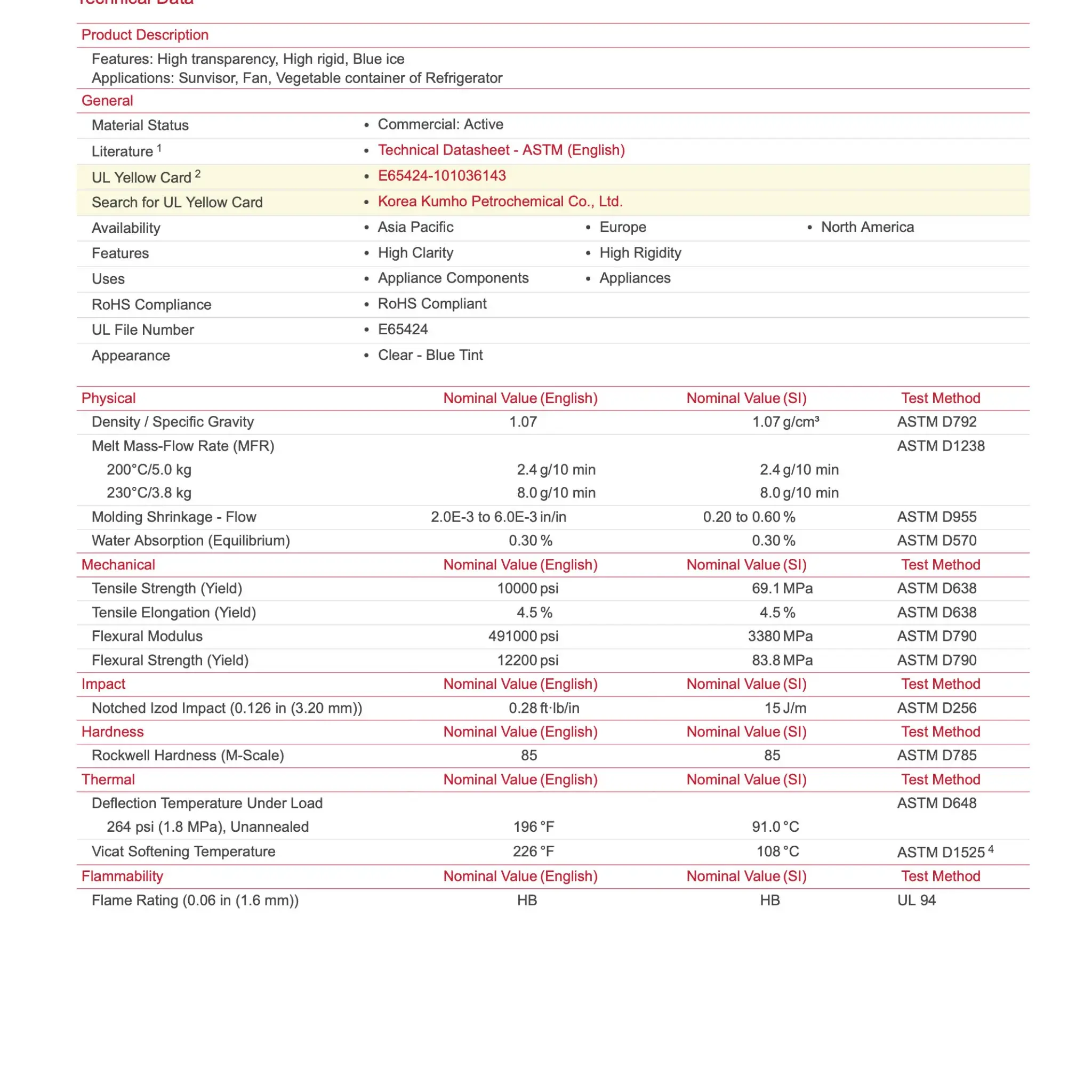

General

Physical ISO 1183 ISO 1133 ISO 1133 Internal Method Internal Method

Mechanical ISO 527-1/1 ISO 527-2/50 ISO 527-2/50 ISO 178 ISO 178 Impact ISO 179 ISO 179

Thermal ISO 75-2/B ISO 75-2/A ISO 11357-3 ISO 11359-2

Electrical IEC 60093 IEC 60093 IEC 60243-1 IEC 60250 IEC 60250 IEC 60112 Flammability UL 94

Injection