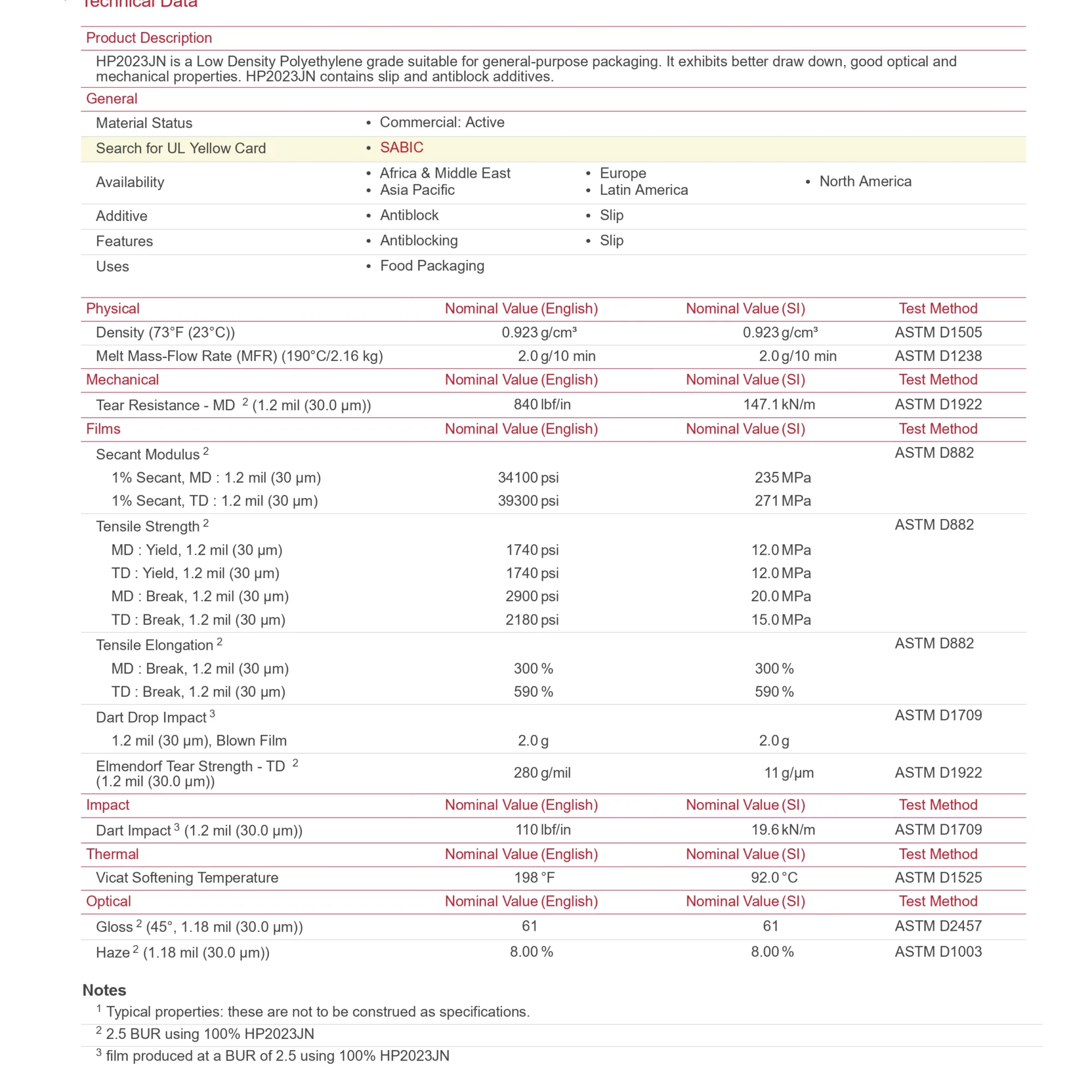

Lupolen LDPE 2427 H is an additivated, low-density polyethylene. It contains an antioxidant, slip, and anti-blocking agent. It is delivered in pellet form. Foodlaw compliance information about this product can be found in the separate product documentation. This product is not intended for use in medical and pharmaceutical applications.

General

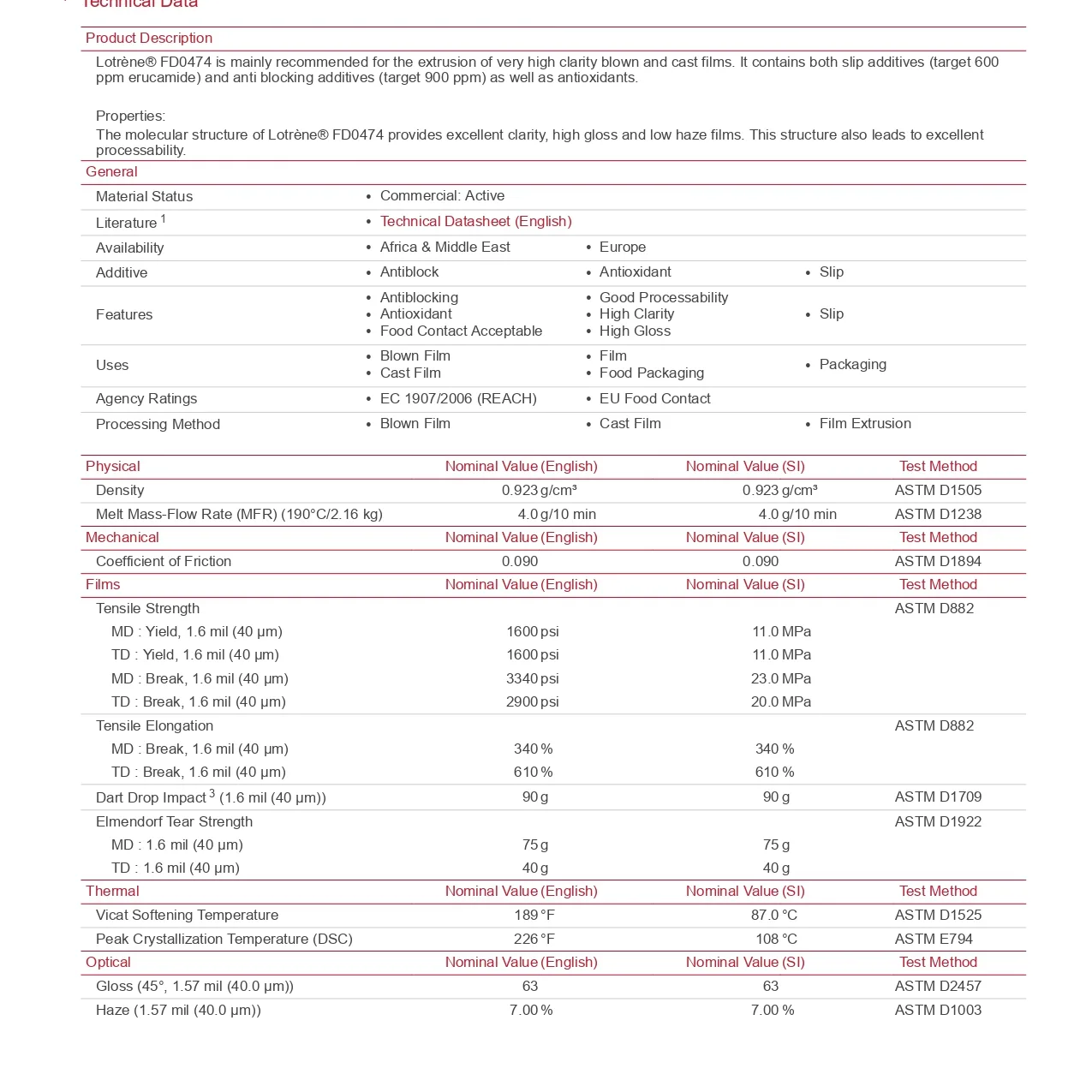

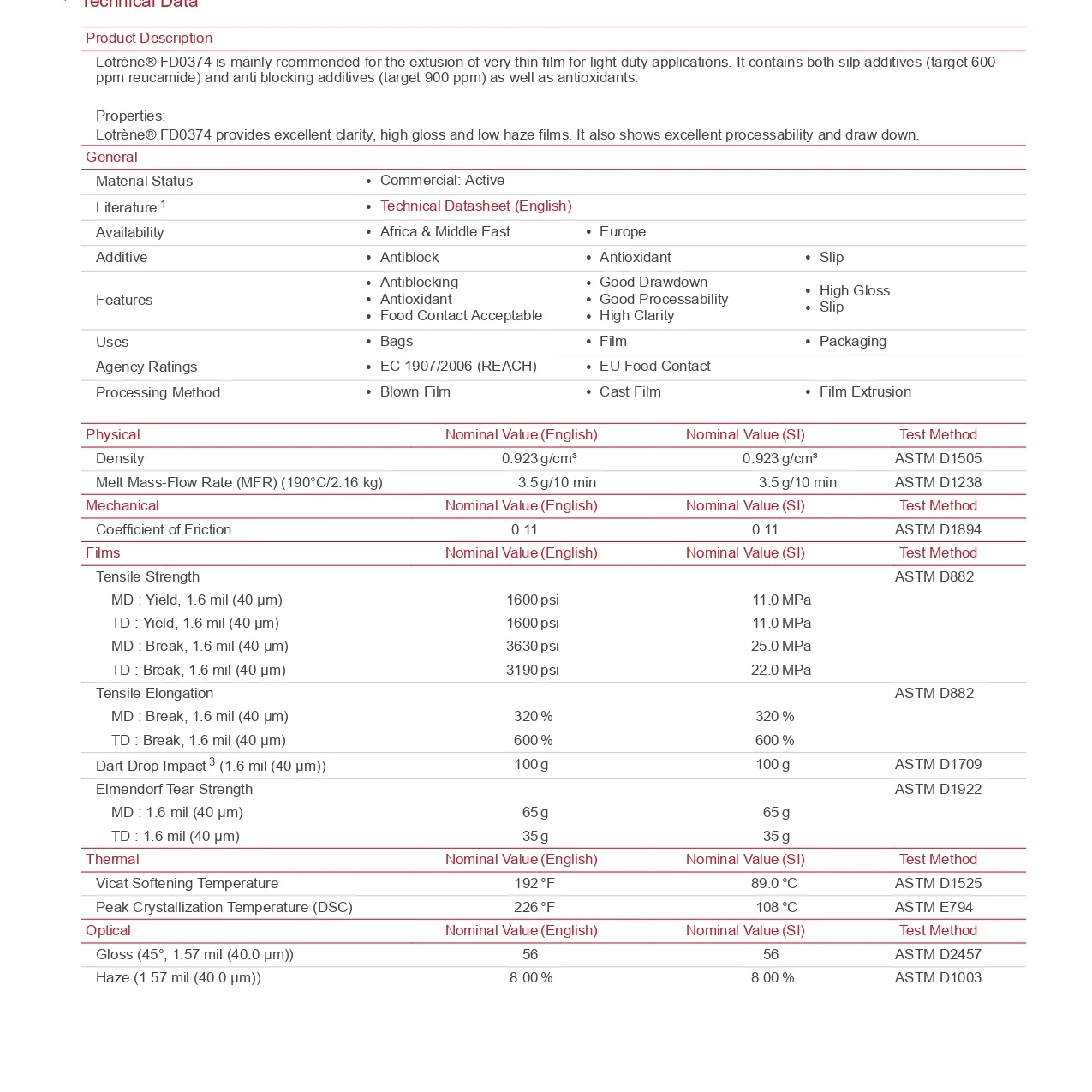

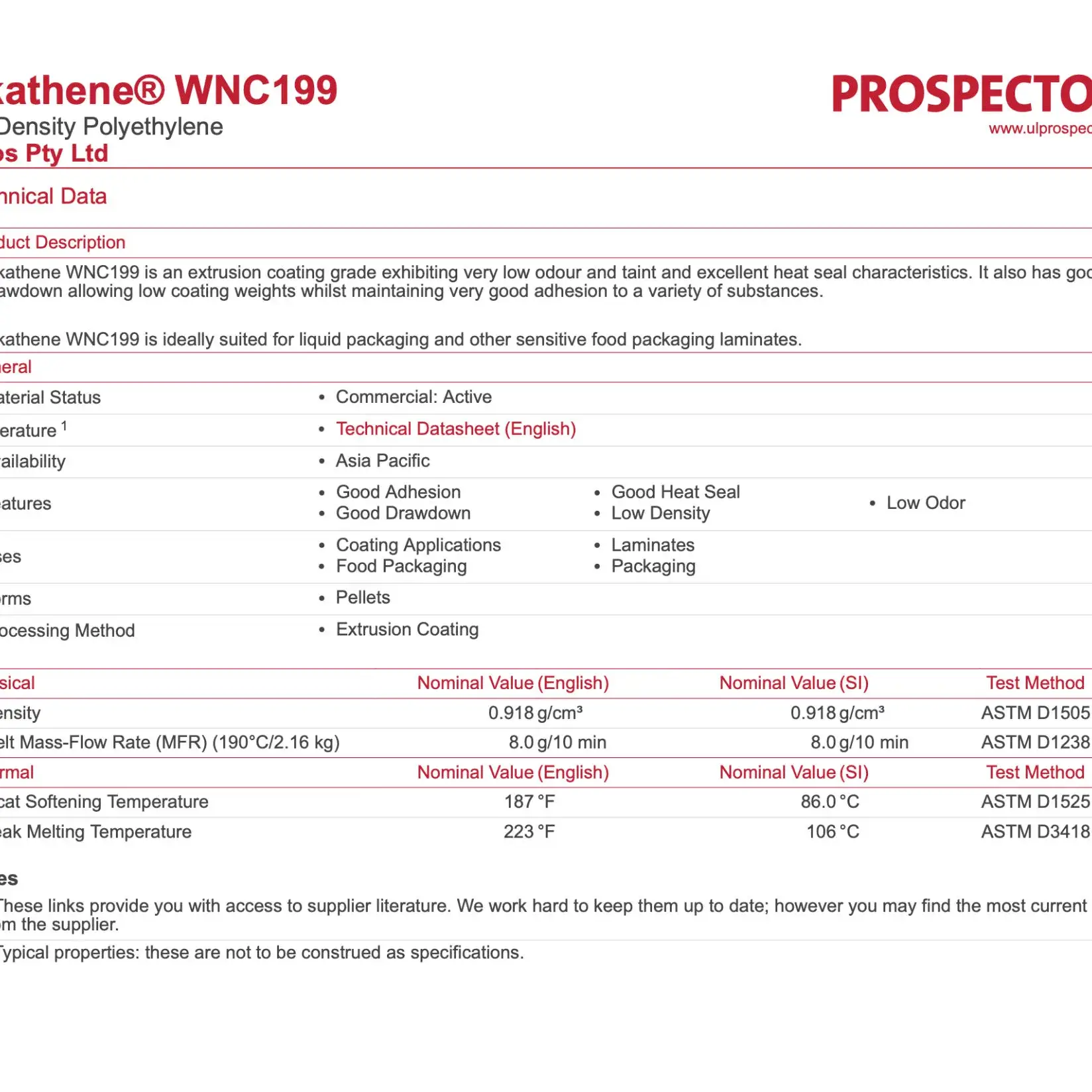

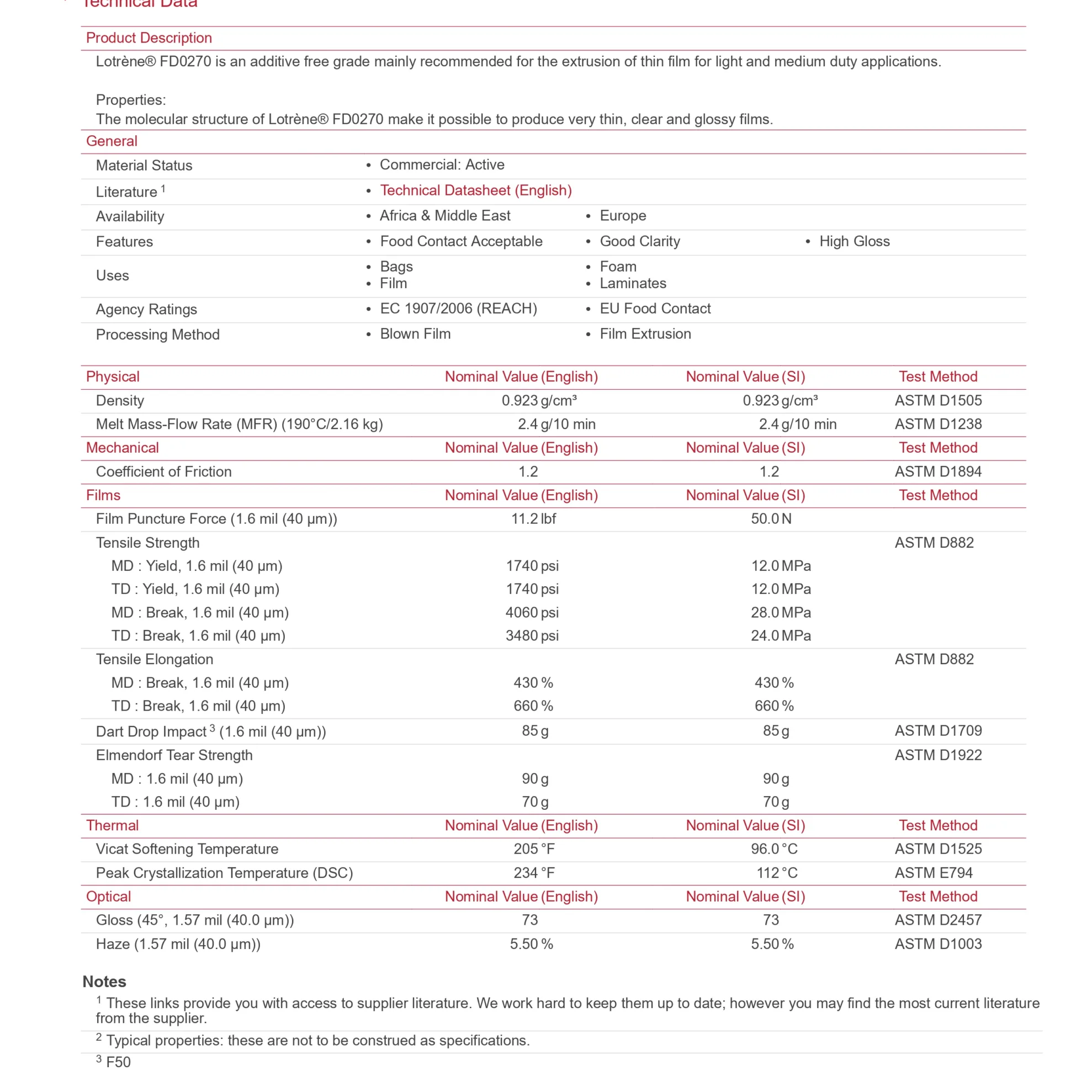

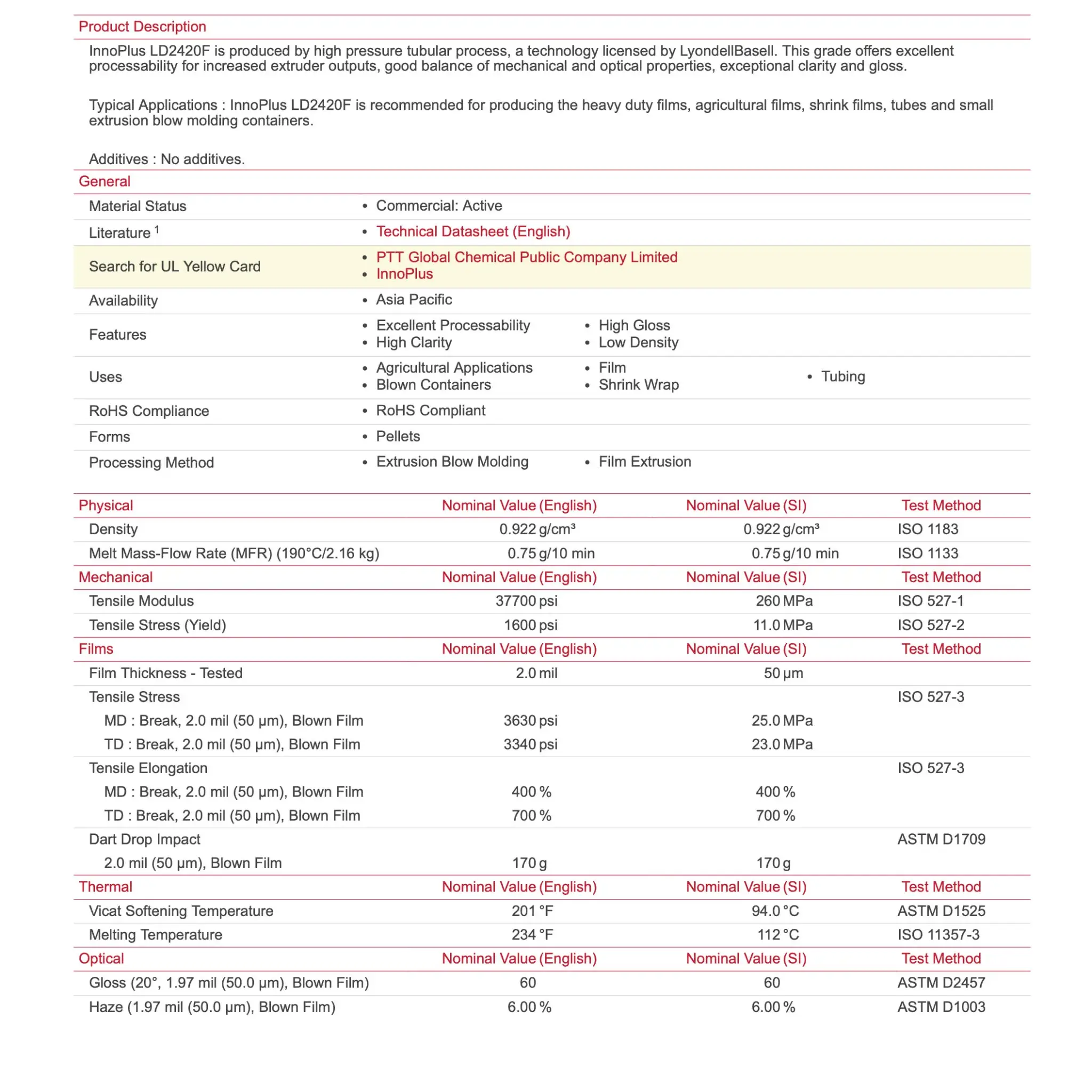

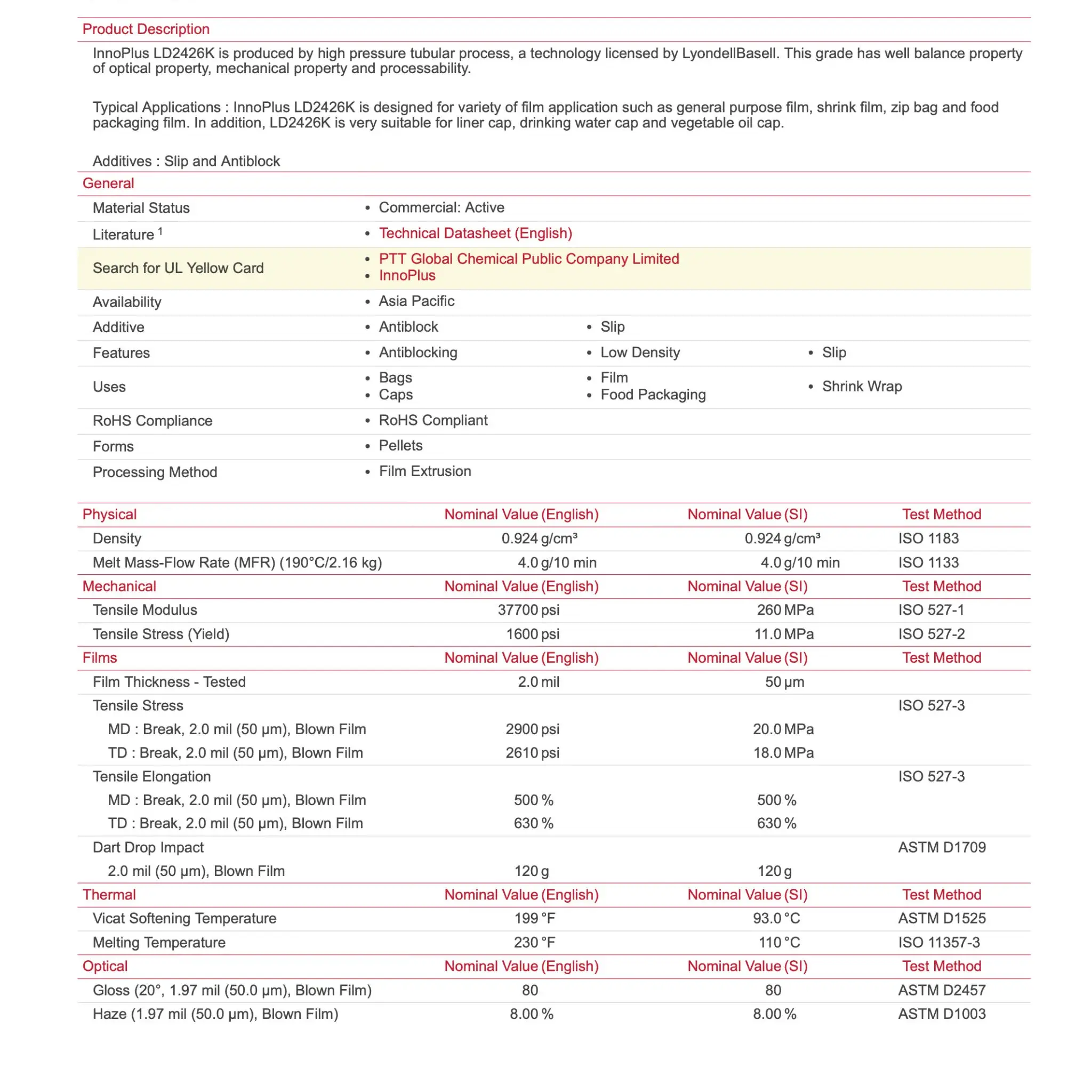

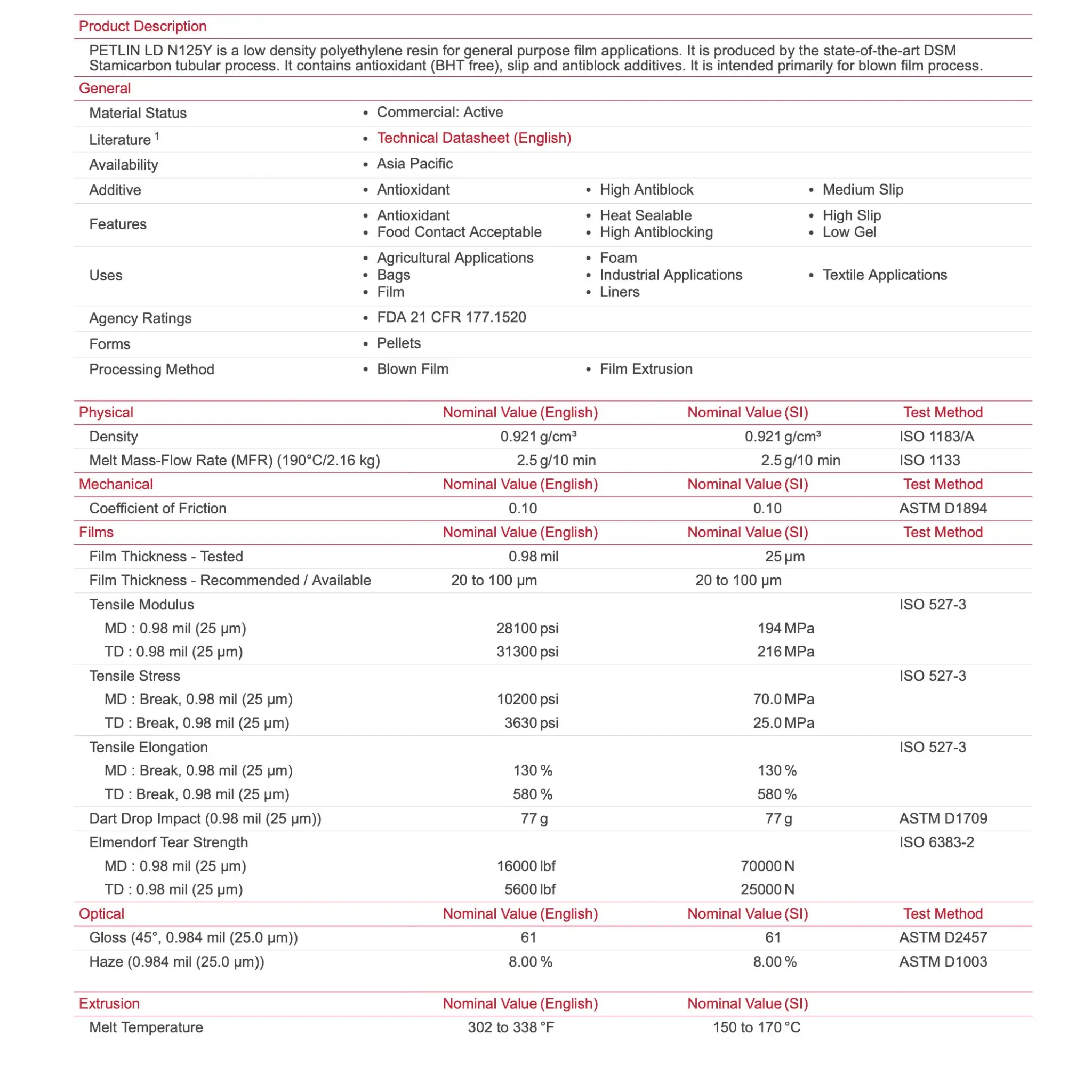

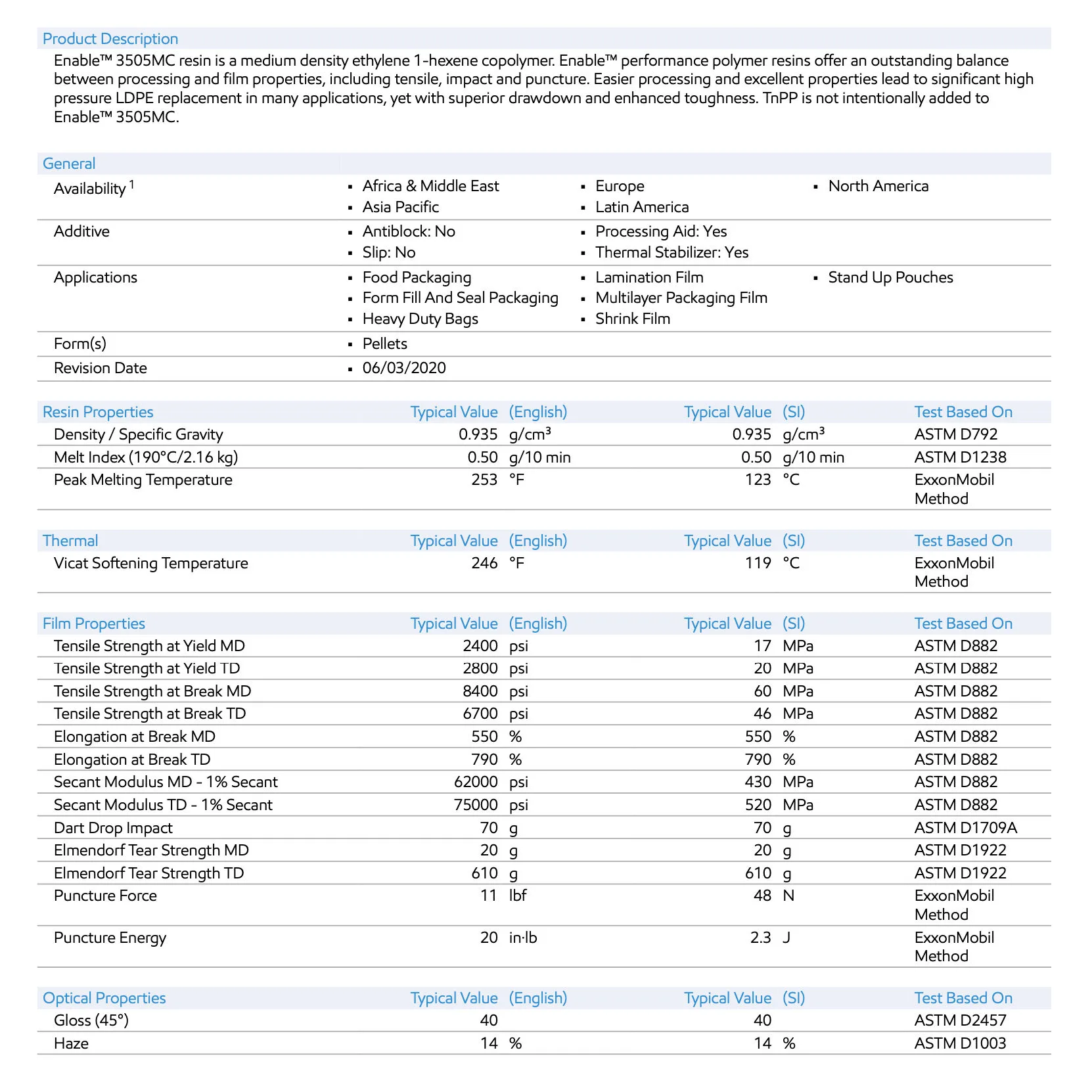

Physical ISO 1183 ISO 1133

Mechanical ISO 527-1 ISO 527-2 ISO 8295 Films ISO 527-3 ISO 527-3 ASTM D1709

Thermal ISO 306/A50 ISO 3146

Optical ASTM D2457 ASTM D1003

Additional Information DIN 51454 DIN 53373 ISO 3451-1

Extrusion