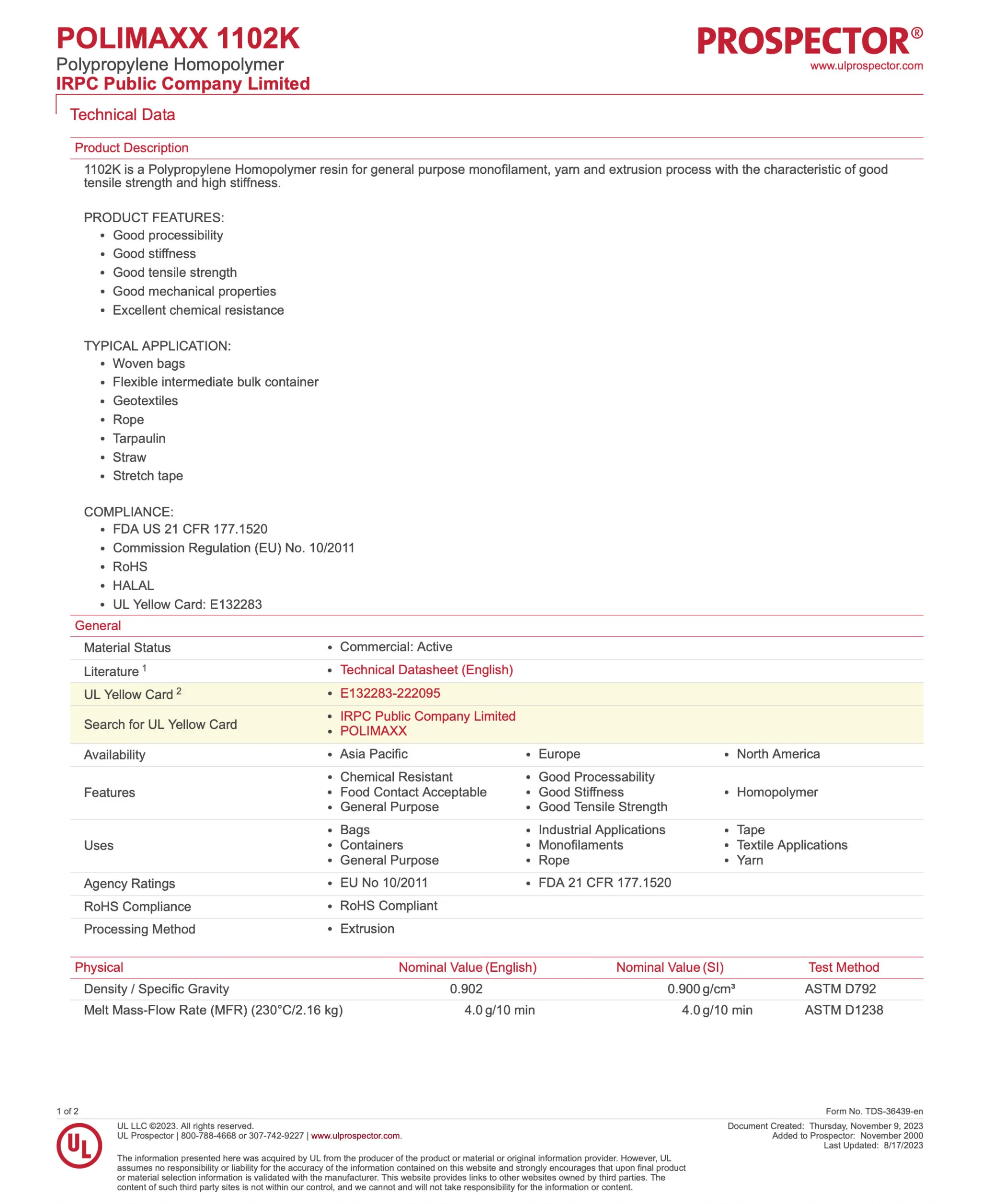

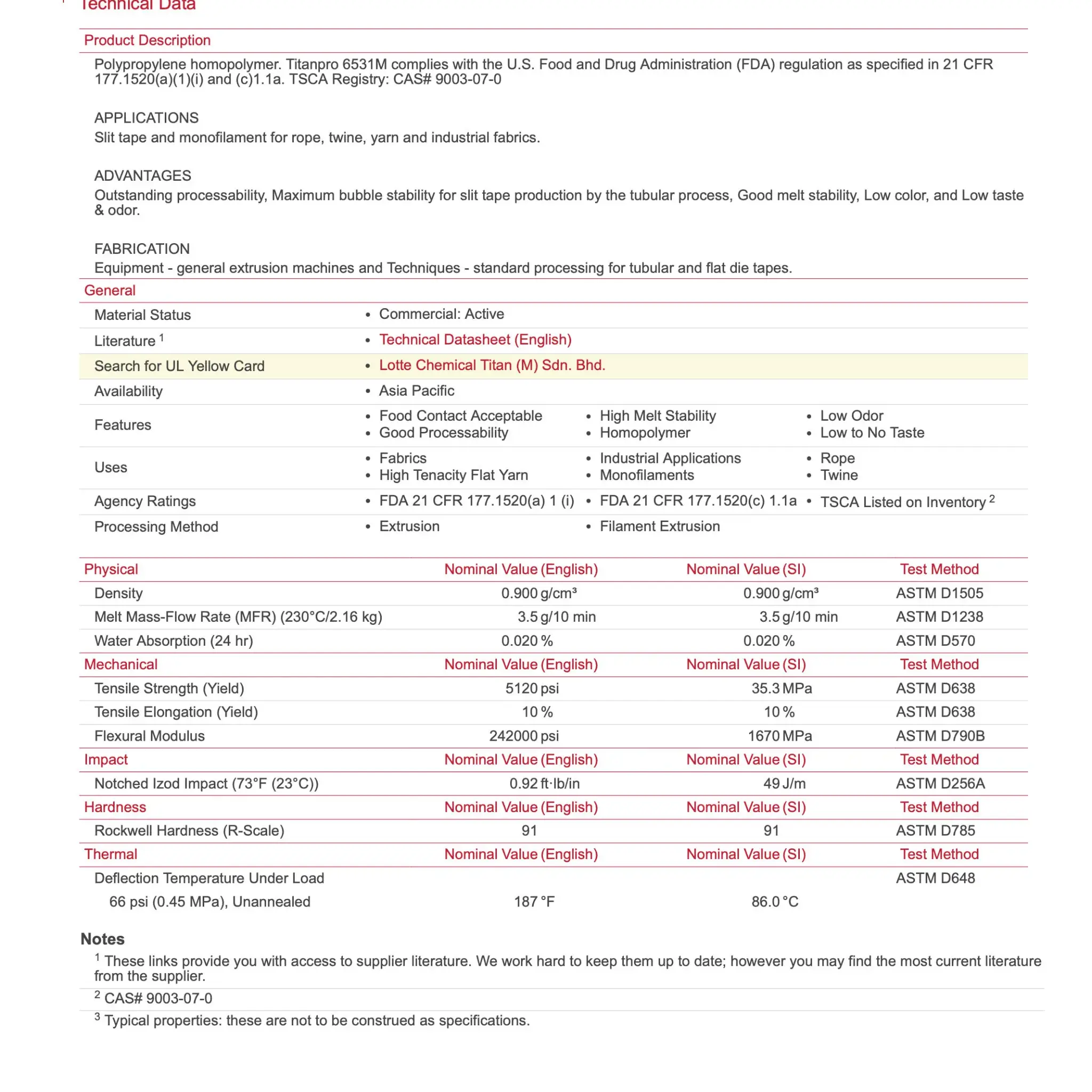

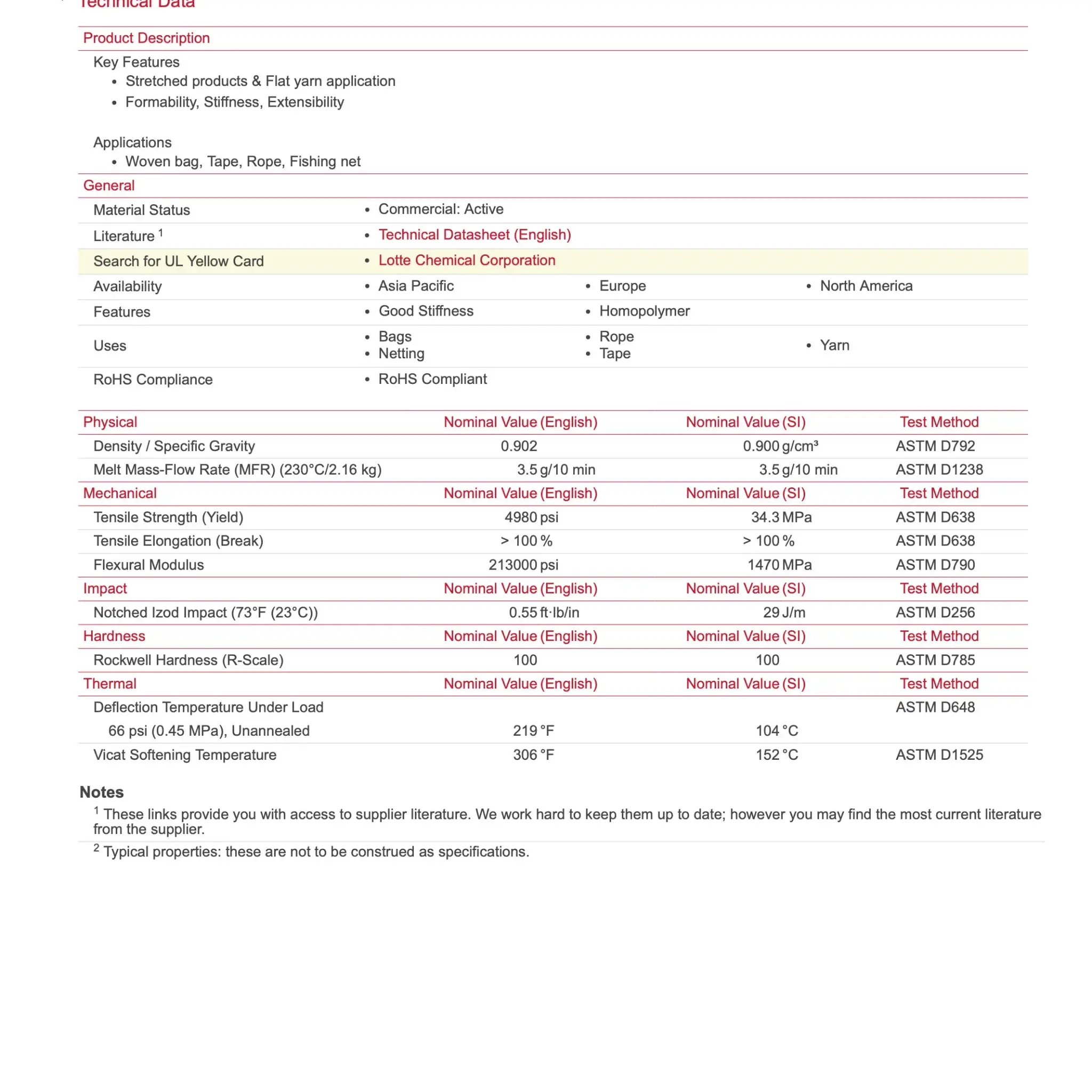

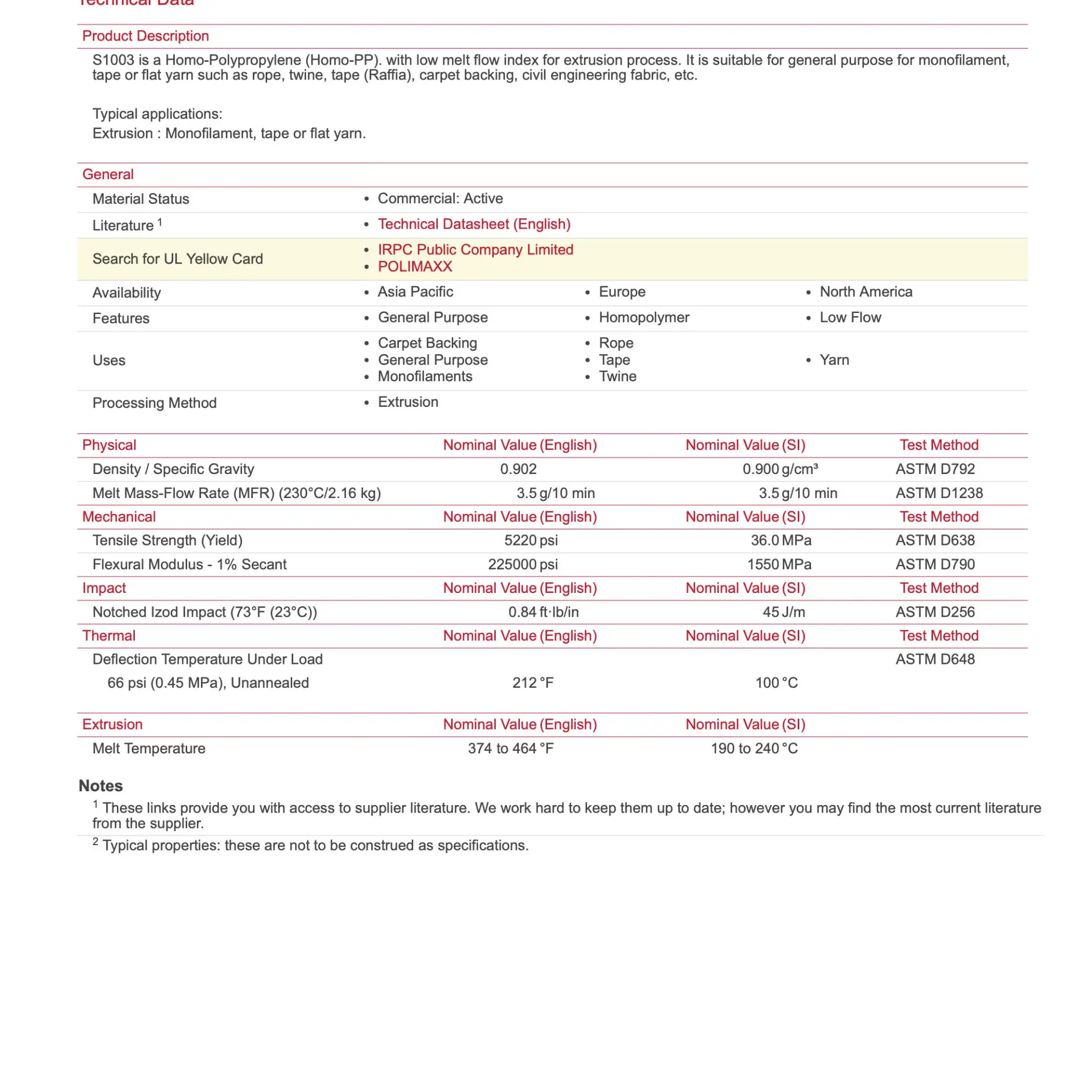

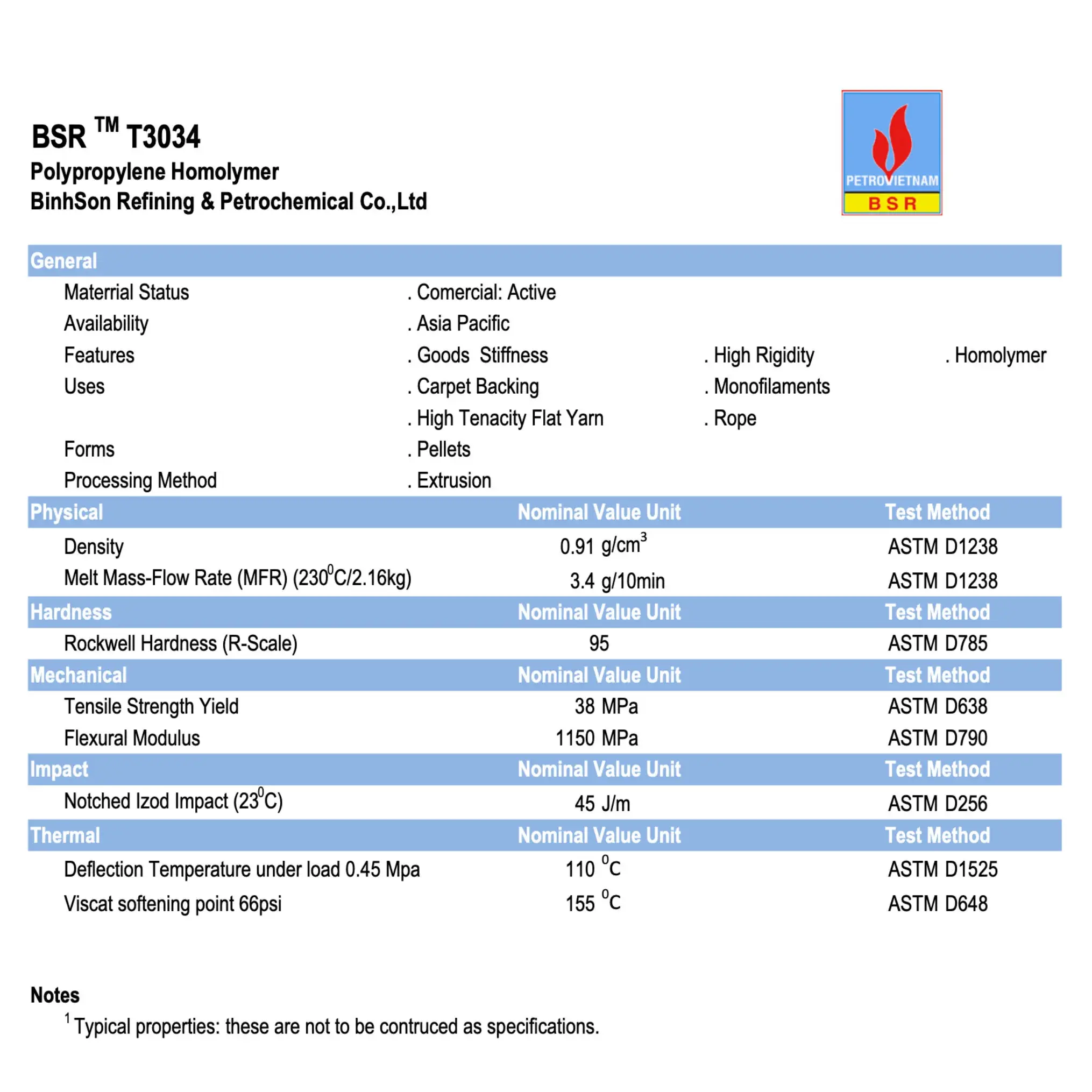

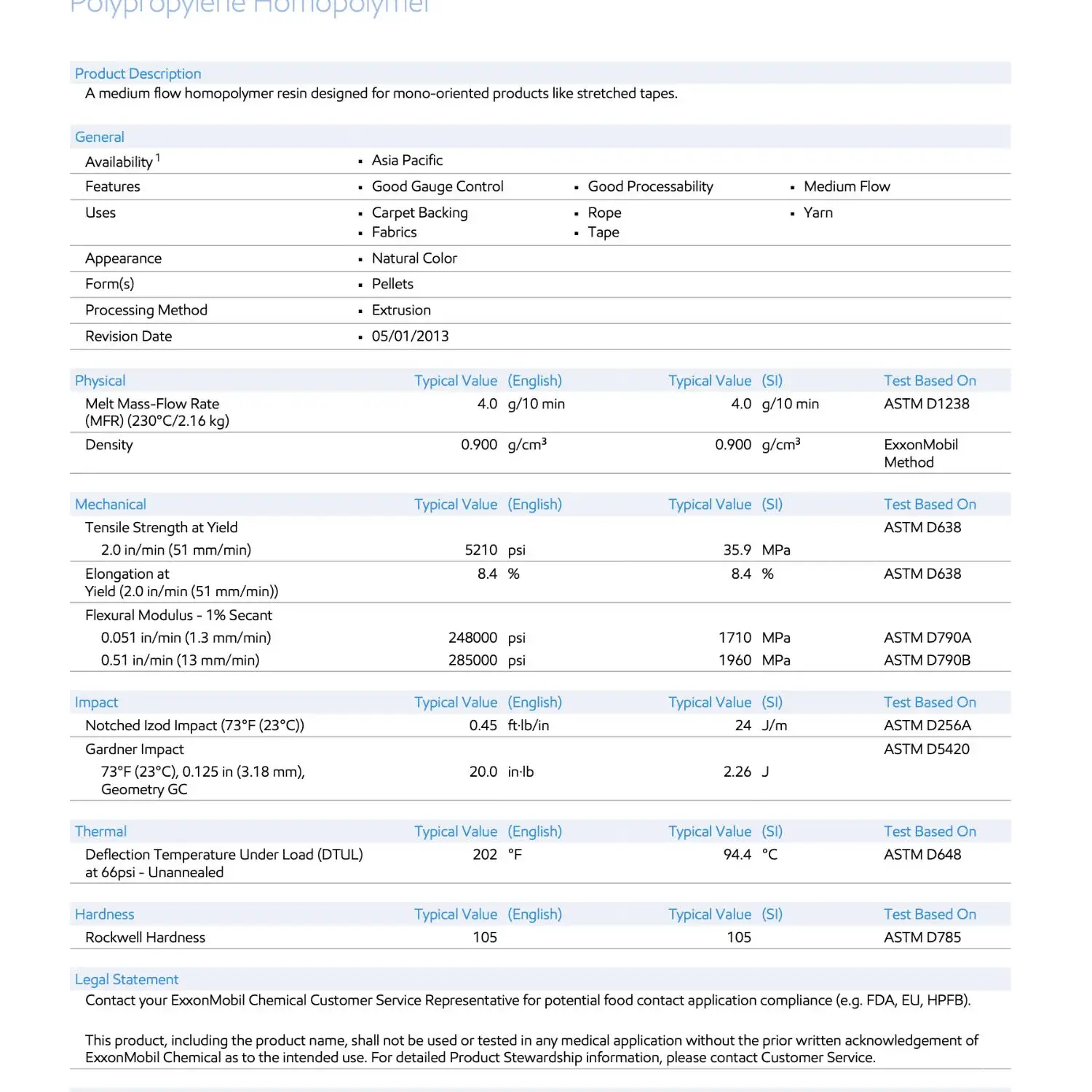

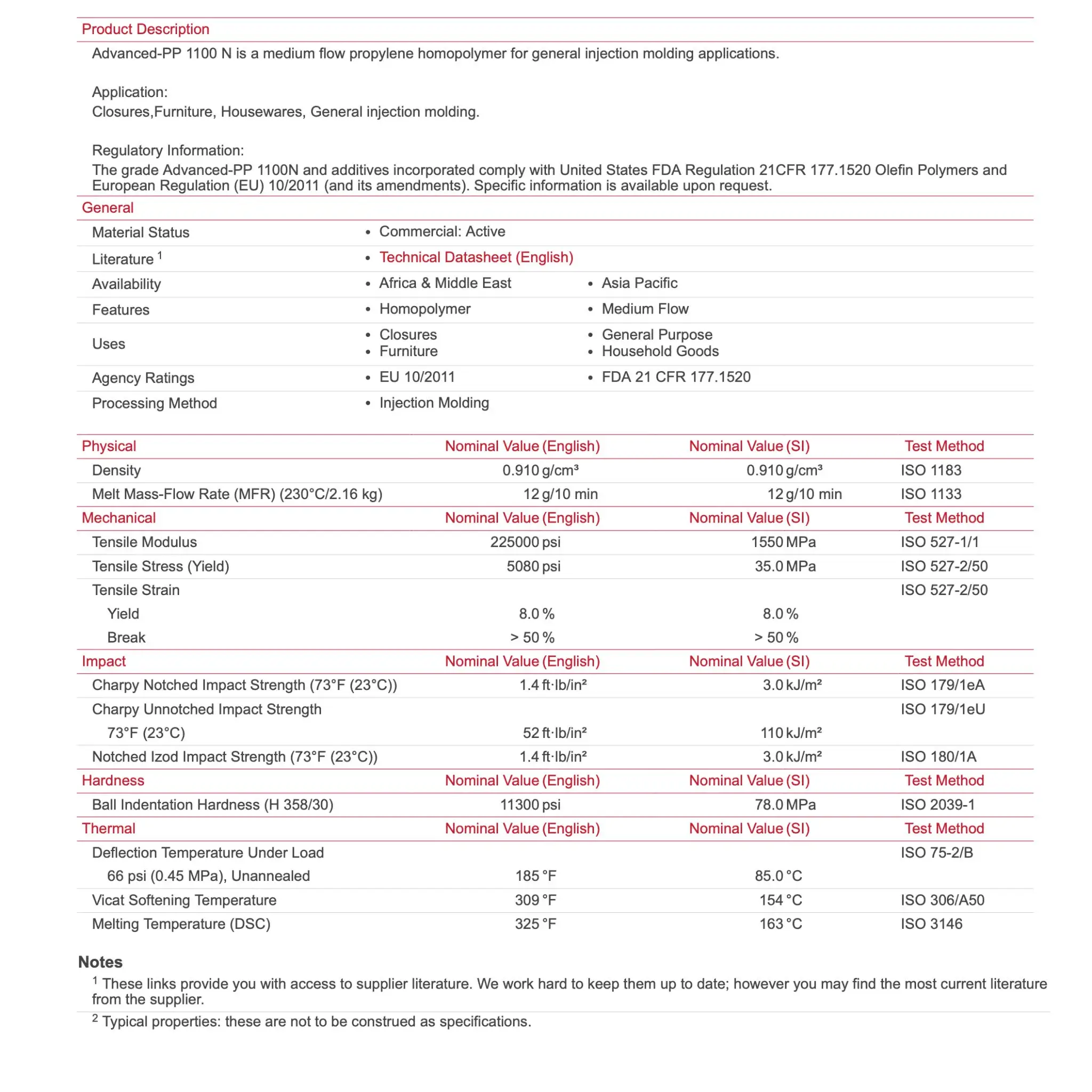

Polimaxx PP 1102K is a Polypropylene Homopolymer resin for general-purpose monofilament, yarn, and extrusion processes with the characteristic of good tensile strength, high stiffness, good processibility, mechanical properties, and excellent chemical resistance.

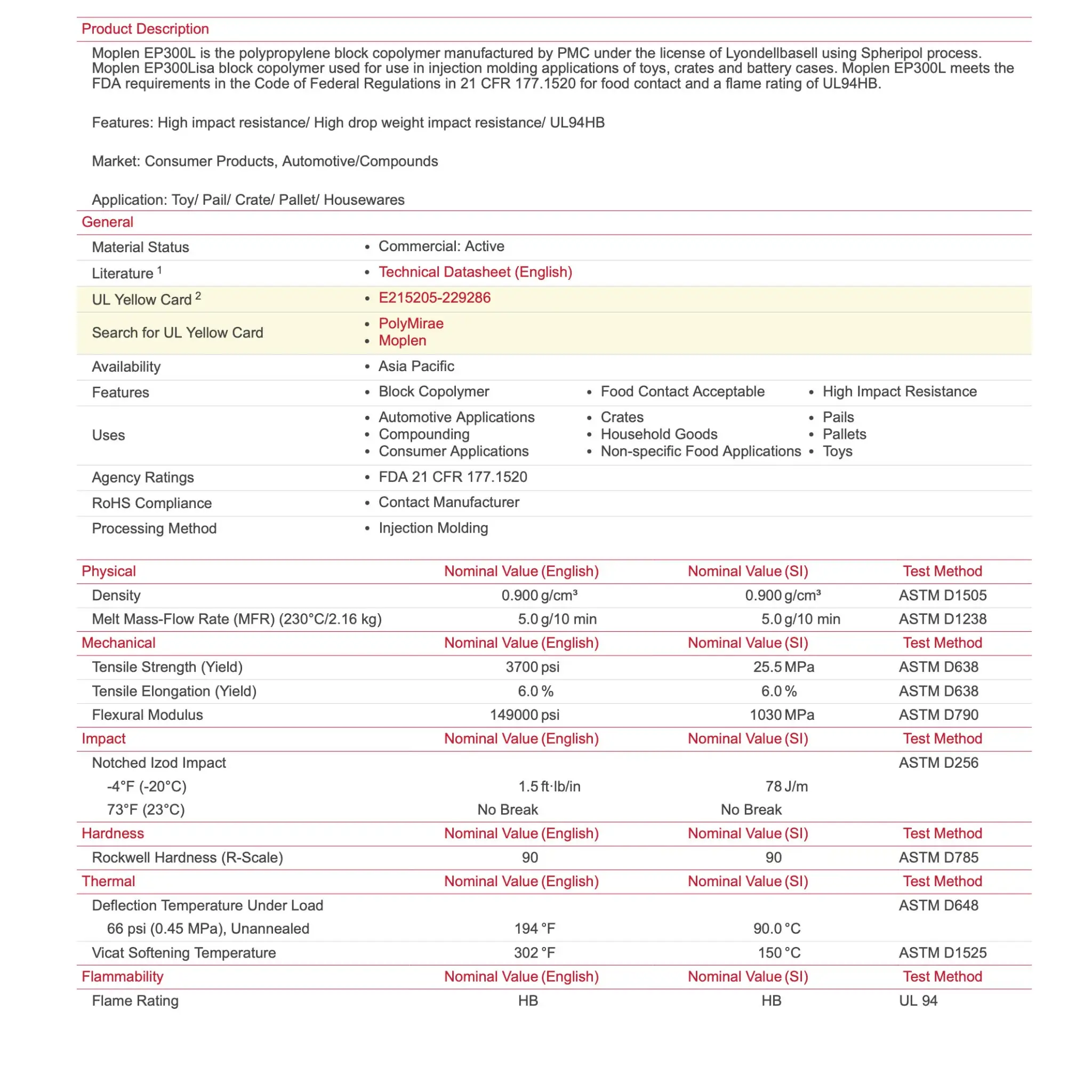

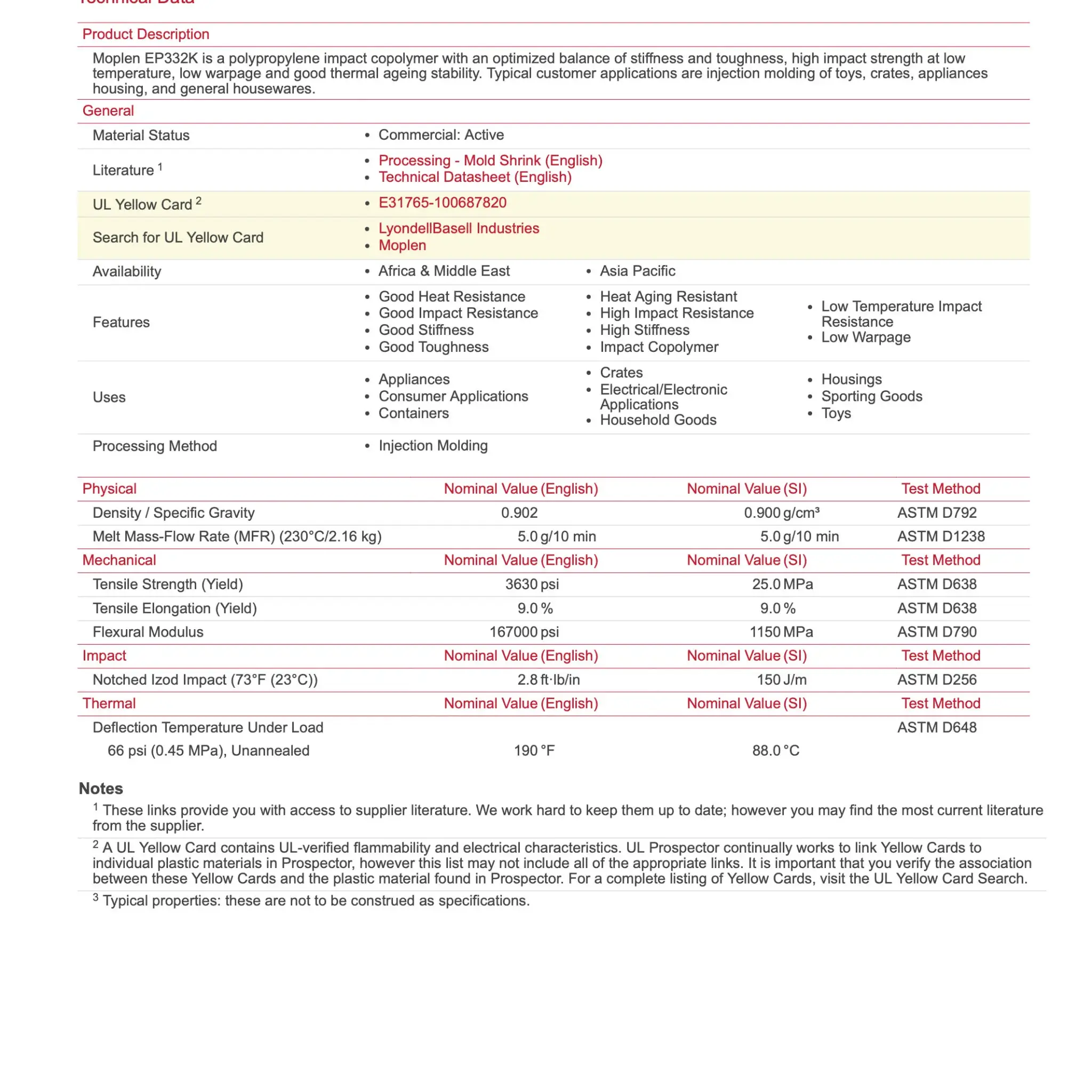

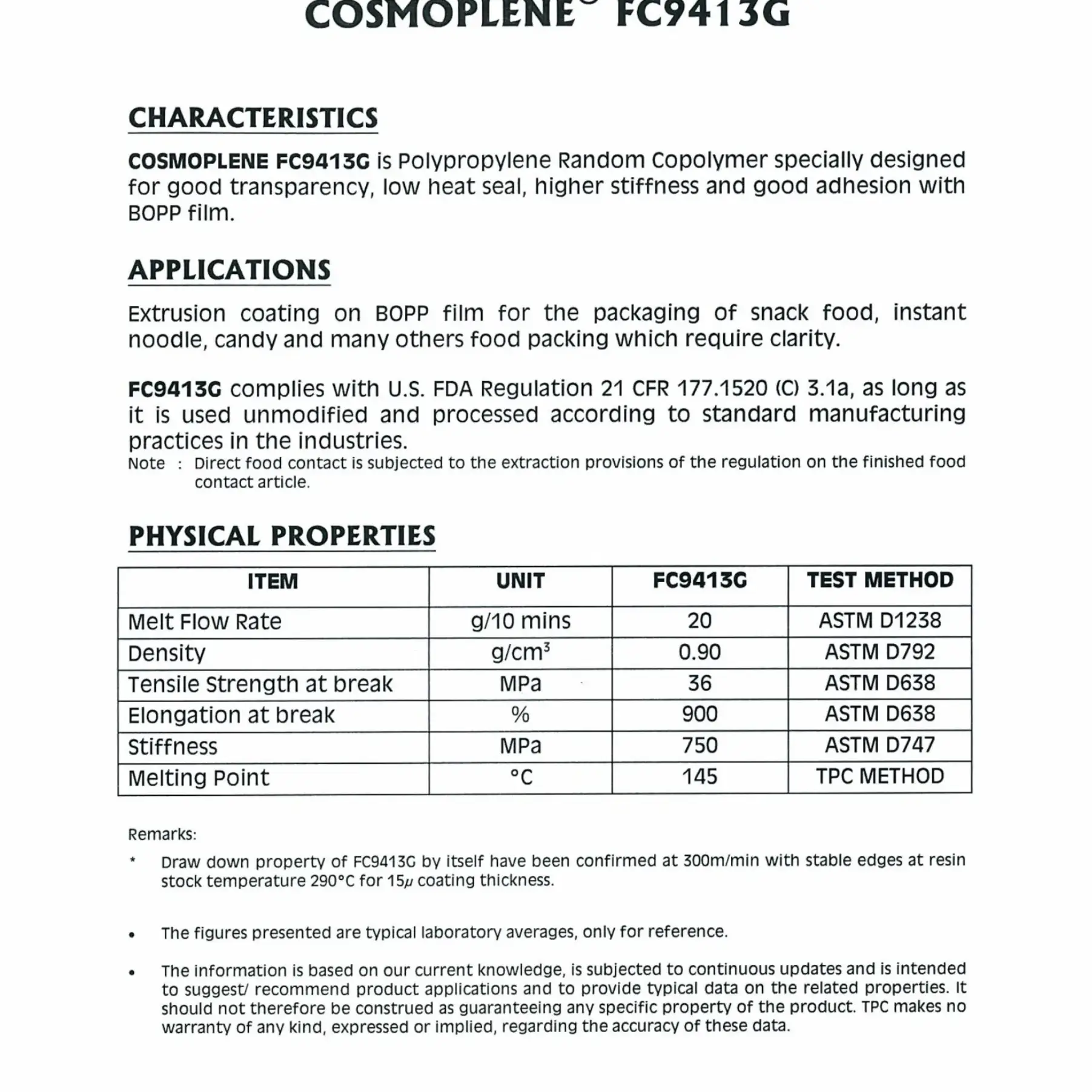

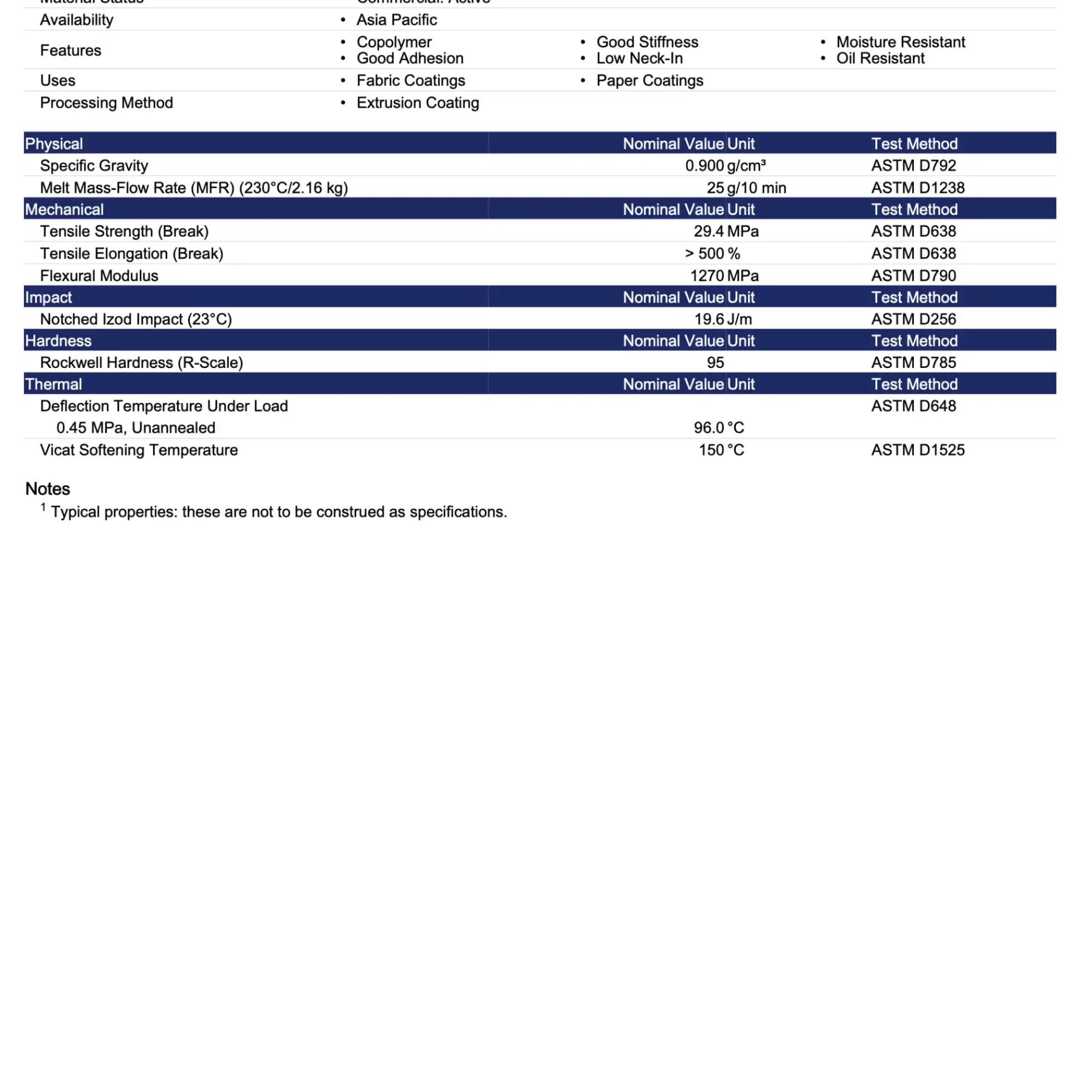

General

Physical ASTM D792 ASTM D1238 Hardness ASTM D785

Mechanical ASTM D638 ASTM D638 ASTM D790 Impact ASTM D256

Thermal ASTM D648

Flammability UL 94

Extrusion